Properly storing your carbon fiber brush is crucial for preserving its effectiveness and longevity. After cleaning, the brush must be kept in a dry, well-ventilated area, protected from direct sunlight and any physical compression that could deform its delicate bristles. This prevents the degradation of the carbon fibers and corrosion of any metal components.

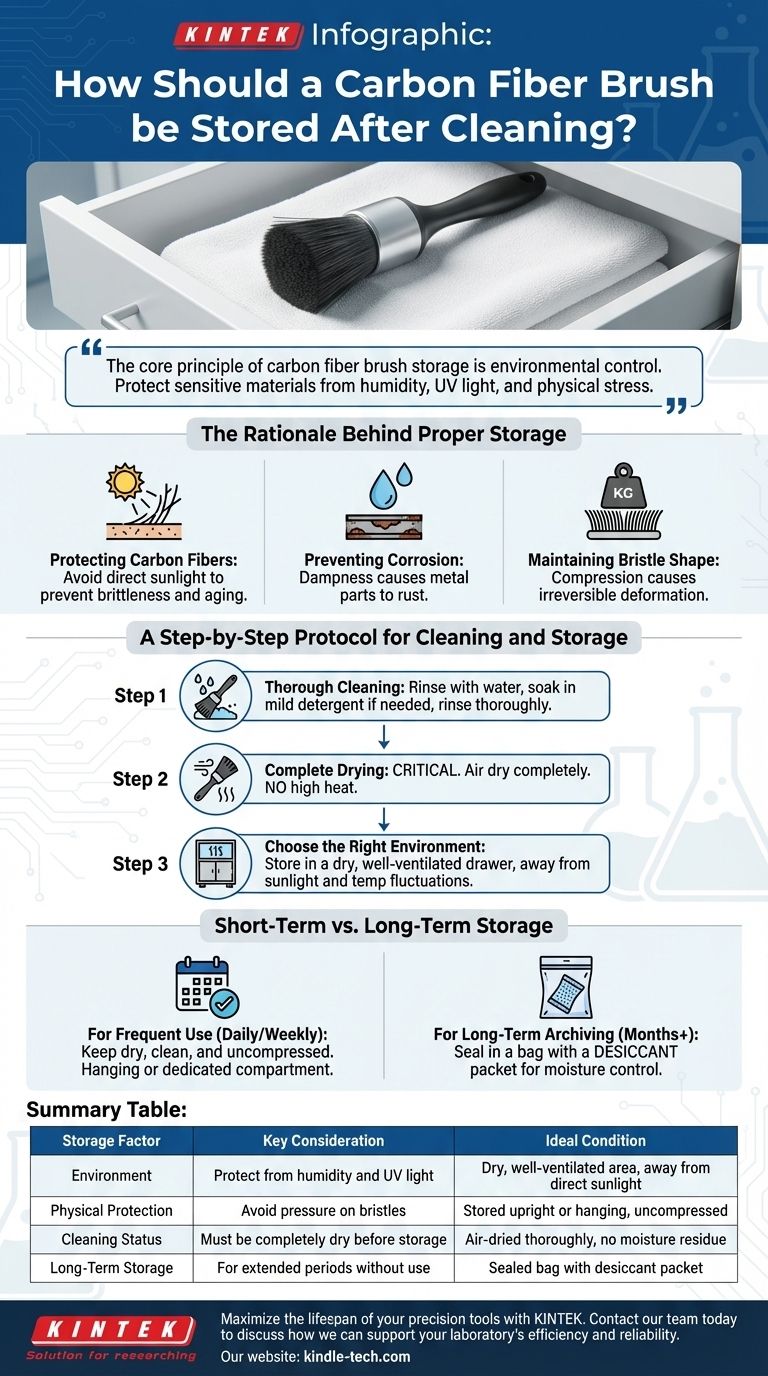

The core principle of carbon fiber brush storage is environmental control. You are not just putting the brush away; you are actively protecting its sensitive materials from humidity, UV light, and physical stress to ensure it performs correctly the next time you need it.

The Rationale Behind Proper Storage

Understanding why these storage steps are necessary helps in applying them correctly. A carbon fiber brush is a precision tool whose performance depends on the integrity of its individual components.

Protecting the Carbon Fibers

The primary function of the brush comes from its carbon fibers. Prolonged exposure to direct sunlight can cause these fibers to become brittle and age prematurely, reducing their cleaning or conductive properties.

Similarly, high humidity can negatively impact the fibers, making proper drying and storage essential.

Preventing Corrosion of Metal Components

Many carbon fiber brushes use metal wires or ferrules to hold the bristles in place. Storing the brush while it is still damp or in a humid environment creates the perfect conditions for these metal parts to rust.

Corrosion compromises the brush's structural integrity and can lead to bristle loss.

Maintaining Bristle Shape and Integrity

The bristles must maintain their original shape to function effectively. Storing the brush in a way that puts weight on the bristles will cause them to bend, splay, or deform permanently.

This damage is irreversible and significantly diminishes the brush's performance, as the bristles will no longer make contact with the target surface as intended.

A Step-by-Step Protocol for Cleaning and Storage

Before you can store the brush, it must be impeccably clean. Storing a dirty brush can trap contaminants and moisture, accelerating its degradation.

Step 1: Thorough Cleaning

First, rinse the brush with clean water to remove any loose debris or visible impurities.

If needed, soak the brush in a mild detergent solution for about 30 minutes to dissolve stubborn contaminants. Gently agitate it to help dislodge particles.

Finally, rinse the brush thoroughly with clean water to remove all traces of detergent residue, which could interfere with its function.

Step 2: Complete Drying

This is a critical step. Before storage, the brush must be completely dry. You can hang it or place it on a clean, dry towel in a well-ventilated area.

Do not use high heat to speed up drying, as this can damage the fibers. Air drying is the safest method.

Step 3: Choose the Right Environment

Once dry, place the brush in a location that is free from humidity and shielded from direct sunlight. A dedicated drawer, cabinet, or storage box is ideal.

Avoid storing it in basements, garages, or other areas prone to significant temperature and humidity fluctuations.

Understanding the Key Difference: Short-Term vs. Long-Term Storage

Your storage method can be adjusted based on how frequently you use the brush.

For Frequent Use

If you use the brush daily or weekly, the primary focus is simply keeping it dry, clean, and uncompressed between uses. Hanging the brush or placing it in its own compartment is sufficient.

For Long-Term Archiving

If you do not plan to use the brush for several months or longer, take extra precautions. Place the completely dry brush inside a sealed bag with a desiccant packet.

This creates a controlled micro-environment that actively absorbs any residual moisture, offering the best possible protection against humidity-related aging and corrosion.

Making the Right Choice for Your Goal

Your storage strategy should align with your usage patterns to maximize the brush's lifespan.

- If your primary focus is daily or weekly use: Keep it simple by ensuring the brush is dry, clean, and stored without any pressure on its bristles.

- If your primary focus is long-term preservation: Use a sealed bag with a desiccant after thorough cleaning and drying to create an ideal archival environment.

Proper care is a direct investment in the tool's future performance and reliability.

Summary Table:

| Storage Factor | Key Consideration | Ideal Condition |

|---|---|---|

| Environment | Protect from humidity and UV light | Dry, well-ventilated area, away from direct sunlight |

| Physical Protection | Avoid pressure on bristles | Stored upright or hanging, uncompressed |

| Cleaning Status | Must be completely dry before storage | Air-dried thoroughly, no moisture residue |

| Long-Term Storage | For extended periods without use | Sealed bag with desiccant packet |

Maximize the lifespan of your precision tools with KINTEK. Proper storage is just one part of maintaining your lab equipment. As your partner in laboratory excellence, KINTEK provides high-quality carbon fiber brushes and consumables designed for durability and peak performance. Our experts can help you select the right tools and establish best practices for your specific lab needs. Contact our team today to discuss how we can support your laboratory's efficiency and reliability.

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity

- What checks should be performed on a carbon fiber brush before use? Ensure Reliability in Your Lab Processes

- Under what conditions should a carbon fiber brush be replaced? Identify Critical Failure to Ensure Performance

- What are the 3 types of biomass? A Guide to Woody, Agricultural, and Waste Sources

- Is a carbon brush a good conductor of electricity? The Surprising Engineering Choice