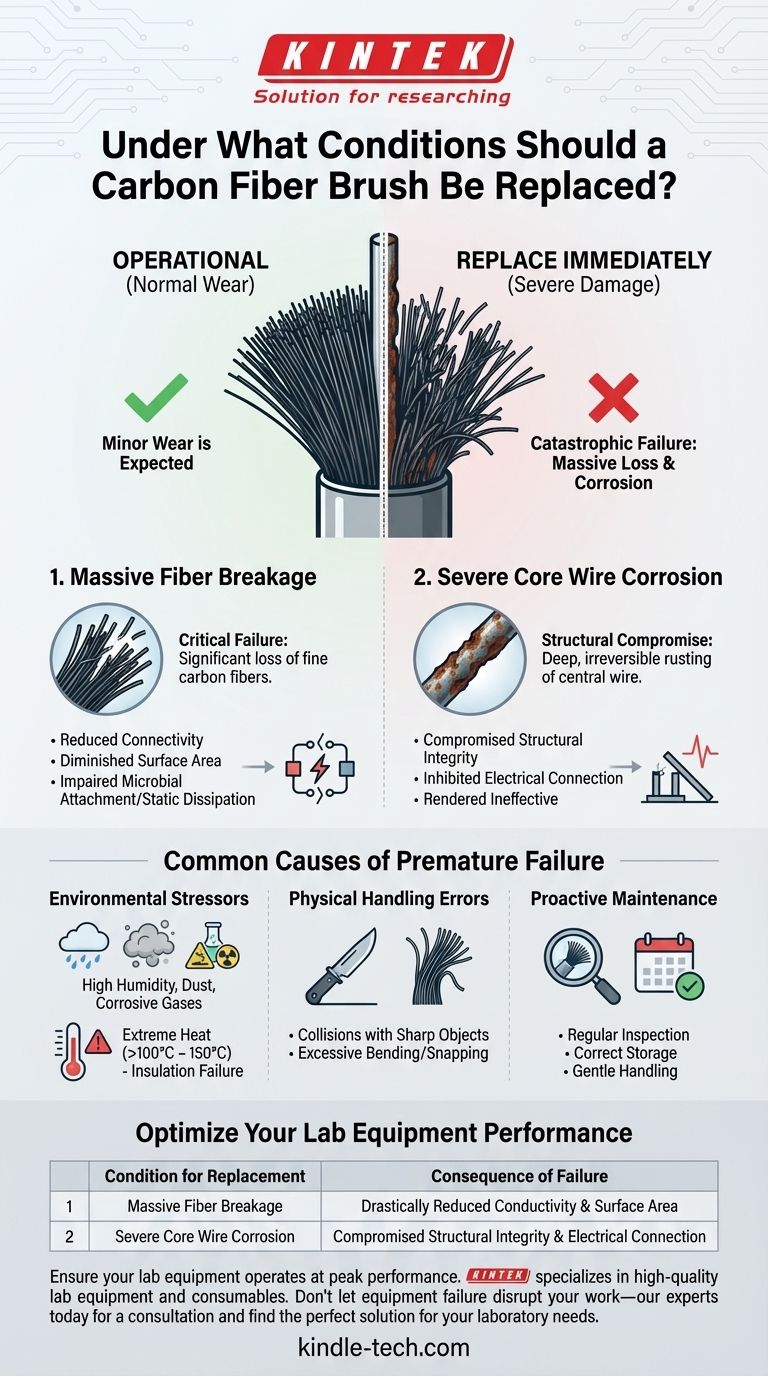

In short, a carbon fiber brush requires replacement only when it suffers severe, irreparable physical damage. This most often includes a massive loss of its fine carbon fibers or deep, irreversible corrosion of its central titanium wire. Minor wear is expected, but catastrophic failure is the key indicator for replacement.

The decision to replace a carbon fiber brush is not based on its age, but on its physical integrity. Once the brush loses a significant portion of its conductive fibers or its core structure is compromised, its performance is irreversibly degraded, and it must be replaced.

Identifying Irreparable Damage

You must learn to distinguish between normal wear and critical failure. The two primary conditions that mandate a replacement are distinct and visually identifiable.

Massive Fiber Breakage

A carbon fiber brush functions through the collective action of thousands of individual fibers. While losing a few strands is not a concern, massive breakage is a critical failure.

This level of damage significantly reduces the brush's overall conductivity. It also diminishes the available surface area, which is crucial for applications relying on microbial attachment or static dissipation.

Severe Core Wire Corrosion

The structural backbone of the brush is typically a titanium wire. While resistant to corrosion, it is not immune, especially in harsh environments.

If you observe severe, irreparable rusting on this central wire, the brush's structural integrity is compromised. This corrosion can also inhibit the electrical connection between the fibers and the terminal, rendering the brush ineffective.

Common Causes of Premature Failure

Understanding what causes a brush to fail is the most effective way to extend its operational life. Failure is almost always rooted in environmental conditions or physical handling.

Environmental Stressors

Certain environments will dramatically accelerate the aging and degradation of a carbon fiber brush. Be vigilant about its placement and storage.

Avoid operating or storing the brush in areas with high humidity, dust, or corrosive gases like acid mist or chlorine. These elements directly attack the fibers and the core wire.

Additionally, keep the brush away from high temperatures. Most carbon fiber brushes have a tolerance that does not exceed 100°C to 150°C, and excessive heat can cause insulation failure or material degradation.

Physical Handling Errors

Carbon fibers are strong but brittle. The brush must be handled with care to prevent the very damage that necessitates replacement.

Always avoid collisions with sharp objects or subjecting the brush to excessive bending. These actions can easily snap large clusters of fibers, immediately reducing the brush's performance.

How to Apply This to Your Maintenance Plan

Use this knowledge to create a clear and effective inspection and replacement strategy. Your decision should be based on direct observation.

- If you observe significant, widespread fiber loss: Replace the brush immediately, as its core functions of conductivity and surface area are permanently compromised.

- If the central wire shows deep, unremovable corrosion: Replace the brush to prevent structural failure and ensure a reliable electrical connection.

- If your brush operates in a harsh environment: Implement a more frequent inspection schedule to catch early signs of corrosion or fiber degradation before they lead to systemic failure.

Proactive inspection and proper handling are the keys to maximizing both the performance and lifespan of your carbon fiber brush.

Summary Table:

| Condition for Replacement | Key Indicator | Consequence of Failure |

|---|---|---|

| Massive Fiber Breakage | Significant loss of conductive carbon fibers | Drastically reduced conductivity and surface area |

| Severe Core Wire Corrosion | Deep, irreversible rusting of the titanium wire | Compromised structural integrity and electrical connection |

Ensure your lab equipment operates at peak performance. A failing carbon fiber brush can compromise your entire system's conductivity and efficiency. KINTEK specializes in high-quality lab equipment and consumables, providing reliable replacements and expert advice to keep your laboratory running smoothly.

Don't let equipment failure disrupt your work—contact our experts today for a consultation and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Graphite Vacuum Continuous Graphitization Furnace

- Laboratory Jaw Crusher

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

- Glassy Carbon Sheet RVC for Electrochemical Experiments

People Also Ask

- How should a carbon fiber brush be stored after cleaning? Preserve Performance and Longevity

- What are 3 types of biomass? A Guide to Wood, Waste, and Biofuels for Energy

- What checks should be performed on a carbon fiber brush before use? Ensure Reliability in Your Lab Processes

- What are 3 benefits of biomass energy? Turn Waste into Renewable Power

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity