Before any use, a carbon fiber brush must undergo a thorough visual and environmental check. You need to inspect the brush for any significant breakage or shedding of fibers, ensure the metal fixing wires are secure and not rusted, and confirm that the intended operational environment (like temperature and humidity) is within the material's specified tolerance range.

A pre-use inspection is not a formality; it is a critical step to guarantee the brush's fundamental properties—its electrical conductivity and physical surface area—are intact. Failing to do so can compromise the validity and efficiency of your entire process.

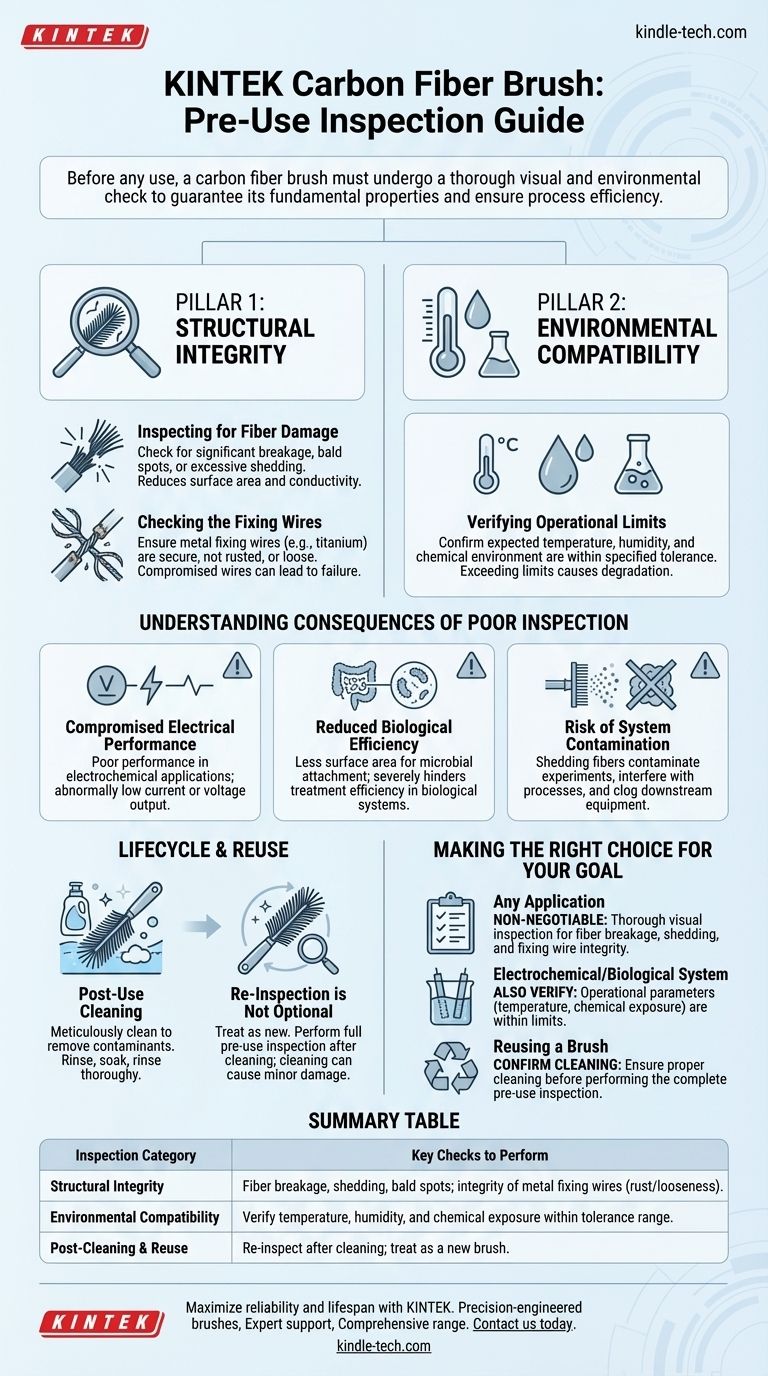

The Two Pillars of Pre-Use Inspection

A reliable carbon fiber brush depends on both its physical structure and its suitability for the intended environment. Your inspection should cover both aspects.

Pillar 1: Structural Integrity

A brush that is physically compromised cannot perform its function correctly.

Inspecting for Fiber Damage The primary function of the brush relies on its dense, high-surface-area fibers. Look for significant breakage, bald spots, or excessive shedding. A large number of broken fibers directly reduces the available surface area for microbial attachment and diminishes the brush's overall electrical conductivity.

Checking the Fixing Wires The carbon fibers are typically held together by metal wires, often titanium. Check that these wires are not loose, broken, or rusted. A compromised fixing wire can lead to the brush falling apart during operation and indicates a potential failure of the core electrical connection point.

Pillar 2: Environmental Compatibility

A structurally sound brush can still fail if it's used in the wrong conditions.

Verifying Operational Limits Before installation, confirm that the expected temperature, humidity, and chemical environment of your system are within the brush material's tolerance range. Exceeding these limits can cause premature degradation of the fibers or fixing wires.

Understanding the Consequences of a Poor Inspection

Skipping these checks introduces significant risks to your project, leading to wasted time and unreliable data.

Compromised Electrical Performance

In electrochemical applications like microbial fuel cells, a damaged brush will exhibit poor performance. You may observe abnormally low current or voltage output, which often points directly back to inadequate conductivity from a faulty brush.

Reduced Biological Efficiency

For wastewater treatment or other biological systems, the brush's vast surface area is essential for cultivating a healthy microbial biofilm. A damaged brush with fewer fibers offers less area for microbes to colonize, severely hindering the system's treatment efficiency.

Risk of System Contamination

A shedding brush releases small carbon fibers into your system. These particulates can contaminate your experiment, interfere with chemical processes, or clog downstream equipment, creating a cascade of problems.

A Note on Brush Lifecycle and Reuse

Proper care extends beyond the pre-use check and is crucial for obtaining repeatable results.

The Importance of Post-Use Cleaning

After use, a brush must be meticulously cleaned to remove contaminants and residual byproducts. A typical process involves rinsing with clean water, soaking in a mild detergent solution, and then rinsing thoroughly again.

Re-Inspection is Not Optional

A cleaned brush must be treated as a new brush. Perform the full pre-use inspection again before it is returned to service, as the cleaning process itself can sometimes cause minor damage.

Making the Right Choice for Your Goal

Your pre-use checklist ensures the brush is fit for purpose from the very start.

- If your primary focus is any application: Your non-negotiable first step is a thorough visual inspection for fiber breakage, shedding, and the integrity of the fixing wires.

- If your primary focus is an electrochemical or biological system: You must also verify that operational parameters like temperature and chemical exposure are within the brush's specified limits.

- If you are reusing a brush: Confirm it has been properly cleaned before performing the complete pre-use inspection as if it were new.

These simple checks are the foundation for achieving reliable, efficient, and repeatable results in your work.

Summary Table:

| Inspection Category | Key Checks to Perform |

|---|---|

| Structural Integrity | Fiber breakage, shedding, bald spots; integrity of metal fixing wires (e.g., titanium) for rust or looseness. |

| Environmental Compatibility | Verify temperature, humidity, and chemical exposure are within the brush's specified tolerance range. |

| Post-Cleaning & Reuse | Re-inspect after cleaning; treat as a new brush to ensure no damage occurred during maintenance. |

Maximize the reliability and lifespan of your lab equipment with KINTEK.

Our carbon fiber brushes are engineered for superior electrical conductivity and durability, making them ideal for electrochemical and biological applications like microbial fuel cells and wastewater treatment.

Why choose KINTEK?

- Precision-engineered brushes that meet strict quality standards for consistent performance.

- Expert support to help you select the right equipment for your specific lab environment and needs.

- Comprehensive range of lab equipment and consumables tailored to enhance efficiency and repeatability in your processes.

Don’t let equipment failure compromise your results. Contact us today to learn how KINTEK’s solutions can support your laboratory’s success!

Visual Guide

Related Products

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Polygon Press Mold for Lab

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Custom PTFE Teflon Parts Manufacturer for Magnetic Stirring Bar

People Also Ask

- Under what conditions should a carbon fiber brush be replaced? Identify Critical Failure to Ensure Performance

- What is the recommended cleaning procedure for a carbon fiber brush after use? Extend Brush Life and Maintain Performance

- What are 3 types of biomass? A Guide to Wood, Waste, and Biofuels for Energy

- How should a carbon fiber brush be stored after cleaning? Preserve Performance and Longevity

- What does the regular maintenance inspection of a carbon fiber brush entail? Ensure Peak Performance and Longevity