When using an X-ray Fluorescence (XRF) analyzer, the most critical precautions involve understanding that the device produces ionizing radiation. Your primary safety measures must be to receive proper training on the specific device, never bypass engineered safety interlocks, always know the direction of the primary X-ray beam, and use the principles of time, distance, and shielding to minimize any potential exposure.

The core issue with XRF safety is not the device itself, but the invisible ionizing radiation it generates. A robust safety protocol, therefore, relies on both respecting the machine's built-in safety features and maintaining strict operator discipline.

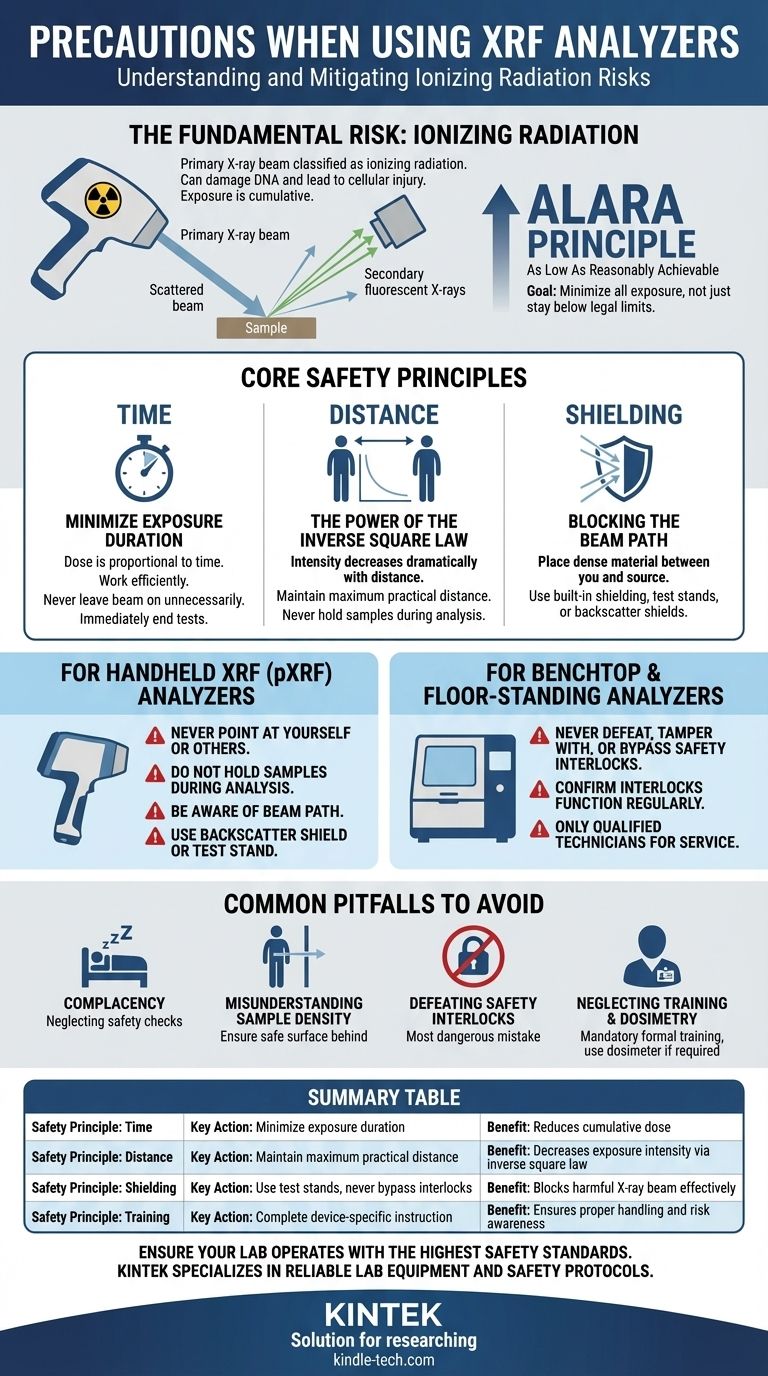

The Fundamental Risk: Understanding Ionizing Radiation

To use an XRF analyzer safely, you must first understand the nature of the risk. The danger comes from a focused beam of X-rays, which is a form of ionizing radiation.

What XRF Analyzers Do

XRF analyzers work by directing a primary X-ray beam at a sample. This energy excites atoms within the sample, causing them to emit secondary, "fluorescent" X-rays. A detector reads these secondary X-rays to identify the elements present in the sample.

The Dangers of the Primary Beam

The primary X-ray beam contains enough energy to be classified as ionizing radiation. This means it can knock electrons out of atoms in living tissue, potentially damaging DNA and leading to cellular injury. Exposure is cumulative, and the goal of all safety protocols is to prevent any unnecessary exposure.

The ALARA Principle

All radiation safety is governed by the ALARA principle: keeping exposure As Low As Reasonably Achievable. This means you should not just stay below the legal dose limits but should actively work to minimize all exposure, no matter how small.

Core Safety Principles in Practice

The three pillars of radiation protection are simple to remember and apply: time, distance, and shielding.

Time: Minimizing Exposure Duration

The total radiation dose you receive is directly proportional to the amount of time you are exposed.

Therefore, you should work efficiently and never leave the analyzer's X-ray beam on unnecessarily. For handheld units, this means taking your reading and then immediately ending the test.

Distance: The Power of the Inverse Square Law

Radiation intensity decreases dramatically with distance from the source. This relationship is described by the inverse square law—if you double your distance from the source, you reduce your exposure to one-quarter of the original intensity.

Always maintain the maximum practical distance from the X-ray source. Never hold a sample in your hand during analysis with a portable unit.

Shielding: Blocking the Beam Path

Shielding involves placing a dense material between you and the radiation source to absorb the energy. Benchtop and floor-standing XRF units have extensive built-in shielding (often lead or thick steel).

For handheld units, the device's housing provides some shielding, but the primary beam is unshielded as it exits the front. A backscatter shield or test stand should be used whenever possible.

Precautions by XRF Type

Safety procedures differ significantly depending on the type of analyzer you are using.

For Handheld XRF Analyzers (pXRF)

These units present the highest potential risk for operator error because the beam is not contained within a shielded chamber.

- Never point the analyzer at yourself or anyone else. Treat it like a loaded gun.

- Do not hold samples during analysis. Use a proper test stand or place the sample on a surface.

- Be aware of the beam path. Ensure no one's hands, feet, or other body parts are underneath the analysis area.

- Use the backscatter shield. This is designed to protect your hands from radiation that scatters off the sample being tested.

For Benchtop and Floor-Standing Analyzers

These units are inherently safer due to their fully enclosed, shielded sample chambers. The primary safety feature is the safety interlock system.

- Never defeat, tamper with, or bypass safety interlocks. These systems are designed to automatically shut off the X-ray beam if the chamber is opened or shielding is compromised.

- Confirm that interlocks are functioning as part of a regular maintenance check.

- Only allow qualified technicians to service the instrument's X-ray tube and shielding components.

Common Pitfalls to Avoid

Even with robust systems, human error and complacency are significant risks.

The Pitfall of Complacency

With enclosed benchtop systems, it is easy to become complacent and forget that a powerful X-ray tube is operating inside. This can lead to the neglect of safety checks or the temptation to bypass an interlock for a "quick test."

Misunderstanding Sample Density

When using a handheld XRF on a low-density material (like plastic, wood, or soil), the primary beam can pass directly through the sample. You must be certain that a dense, safe surface is behind your sample to absorb the beam.

Defeating Safety Interlocks

Bypassing an interlock on an enclosed system to measure an oversized sample is one of the most dangerous mistakes an operator can make. This practice exposes the user to the direct, unshielded primary beam.

Neglecting Training and Dosimetry

Formal training for your specific device is not optional. Furthermore, if required by your institution or local regulations (common for handheld XRF users), wearing your assigned dosimeter (radiation badge) is mandatory for tracking cumulative exposure.

Making the Right Choice for Your Goal

Your safety protocol should be tailored to your specific equipment and working environment.

- If your primary focus is operating a handheld XRF: Your safety depends on constant operator vigilance, particularly regarding the beam's direction and the use of test stands instead of holding samples.

- If your primary focus is managing a lab with a benchtop XRF: Your main responsibility is to ensure no one ever bypasses the safety interlocks and that all users are trained to respect the machine's engineered controls.

- If your primary focus is developing an organizational safety policy: Your policy must mandate manufacturer-approved training for all operators, regular functionality tests of safety interlocks, and strict adherence to the ALARA principle.

Ultimately, safe and effective XRF analysis is achieved by combining a clear understanding of the radiation risk with disciplined adherence to established safety procedures.

Summary Table:

| Safety Principle | Key Action | Benefit |

|---|---|---|

| Time | Minimize exposure duration | Reduces cumulative radiation dose |

| Distance | Maintain maximum practical distance | Decreases exposure intensity via inverse square law |

| Shielding | Use test stands and never bypass interlocks | Blocks harmful X-ray beam effectively |

| Training | Complete device-specific instruction | Ensures proper handling and risk awareness |

Ensure your lab operates with the highest safety standards. KINTEK specializes in providing reliable lab equipment and consumables, including XRF analyzers and safety accessories. Our experts can help you select the right equipment and develop robust safety protocols tailored to your laboratory's needs. Contact us today to enhance your lab's safety and efficiency!

Visual Guide

Related Products

- Customizable XRD Sample Holders for Diverse Research Applications

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What products are made by roll forming? Discover the Versatile Applications Across Industries

- What is the difference between plate and frame and recessed chamber filter press? Flexibility vs. Efficiency

- What is the function of a laboratory hydraulic press in solid-state battery assembly? Achieve Superior Densification

- How do laboratory hydraulic presses and specialized molds influence all-solid-state batteries? Boost Cell Performance

- Do hydraulic presses use electricity? Powering Industrial Force with Electric Motors

- How thick is XRF coating? Measure Metallic Coatings from Nanometers to 100µm

- How accurate is the XRF measurement? Unlock the True Potential of Your Material Analysis