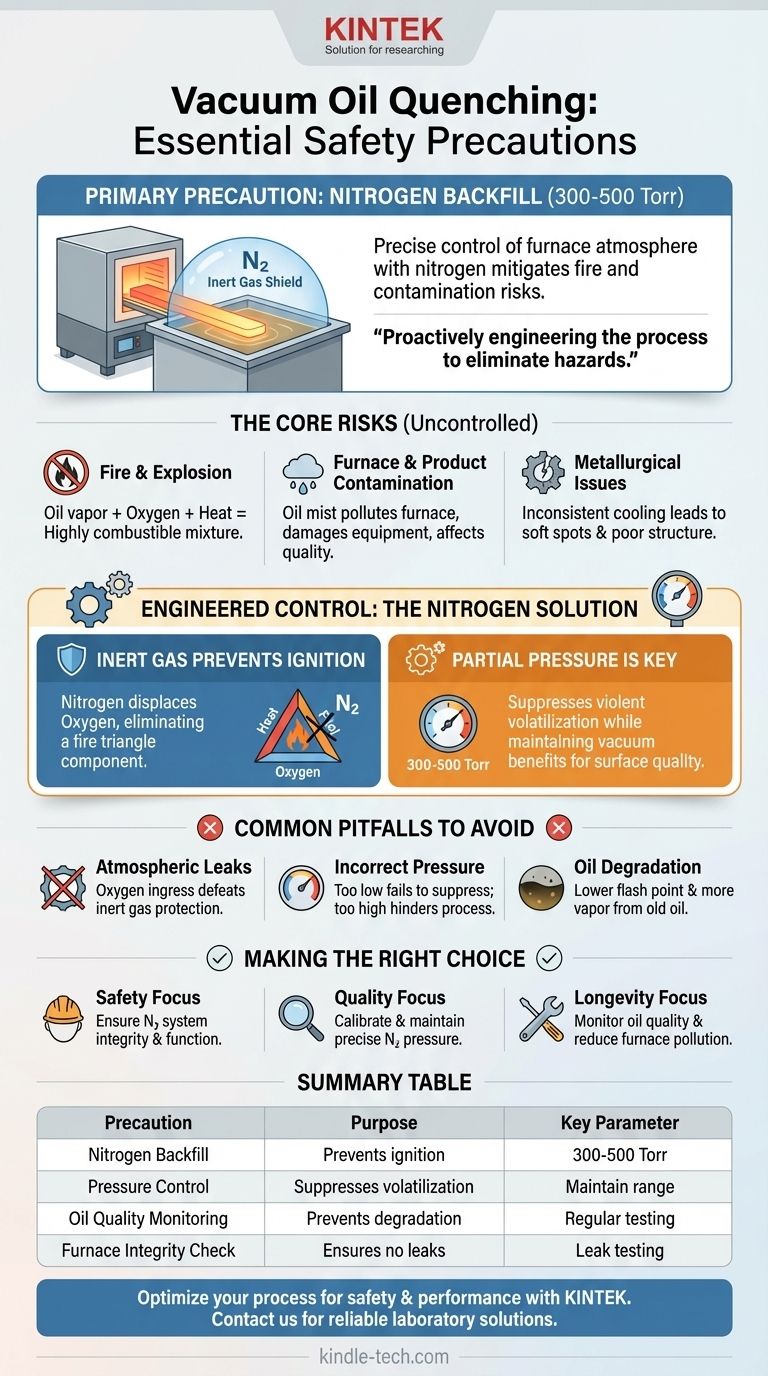

A primary safety precaution during vacuum oil quenching is the precise control of the furnace atmosphere. Specifically, the oil cooling chamber should be backfilled with nitrogen to a partial pressure of 300-500 Torr (approximately 0.4-0.67 x 10⁵ Pa). This engineered control is designed to mitigate the inherent fire and contamination risks associated with hot workpieces being introduced to quenching oil.

The most critical aspect of quenching safety is not merely reacting to hazards, but proactively engineering the process to eliminate them. Controlling the furnace atmosphere with an inert gas like nitrogen is a fundamental engineering control that prevents the formation of a flammable or contaminated environment from the start.

The Core Risks of Uncontrolled Quenching

To implement effective safety measures, you must first understand the fundamental hazards of introducing a hot component into a quenching medium like oil, especially within an enclosed vacuum furnace.

The Danger of Volatilization and Oil Mist

When a hot workpiece enters the quench oil, the intense heat causes the oil at the interface to vaporize instantly. This creates oil vapor and a fine mist.

In an uncontrolled atmosphere, this vapor and mist can mix with any residual oxygen, creating a highly combustible or explosive mixture. A single spark or the component's own heat could be enough to ignite it.

The Threat of Furnace and Product Contamination

The oil vapor doesn't just pose a fire risk. It can travel throughout the furnace, condensing on cooler surfaces.

This leads to significant furnace pollution, increasing maintenance requirements and potentially damaging sensitive equipment. It can also contaminate subsequent batches, negatively impacting product quality and consistency.

The Impact on Metallurgical Properties

Safety and product quality are directly linked. The nitrogen backfill mentioned in the procedure does more than prevent fires.

By applying this partial pressure, the nitrogen improves the cooling capacity of the oil. This ensures a more effective quench, allowing the workpiece to achieve the desired hardness and metallurgical structure. An uncontrolled quench can lead to soft spots or inconsistent results.

Engineered Controls: The Nitrogen Backfill

The most effective safety measures are those designed into the process itself. The use of a nitrogen backfill is a perfect example of such an engineering control.

How Inert Gas Prevents Ignition

Nitrogen is an inert gas, meaning it does not react or support combustion. By filling the chamber, it displaces any residual oxygen.

This eliminates one of the three components of the fire triangle (heat, fuel, oxygen). Without oxygen, the oil vapor and mist simply cannot ignite, neutralizing the primary safety hazard.

Why Partial Pressure is Key

The process specifies a pressure of 300-500 Torr, which is a partial vacuum, not a full atmospheric pressurization.

This specific pressure is high enough to suppress the violent volatilization of the quenching oil, reducing the amount of vapor and mist generated. However, it's still low enough to maintain the benefits of a vacuum environment, preventing unwanted oxidation on the part's surface.

Common Pitfalls to Avoid

Implementing this procedure correctly requires attention to detail. Failures often stem from overlooking key process parameters.

Neglecting Atmospheric Integrity

Assuming the vacuum itself is enough for safety is a critical mistake. Leaks in the furnace can introduce oxygen, and without the protective nitrogen backfill, a flammable mixture can form unexpectedly.

Incorrect Pressure Settings

Using a pressure that is too low will fail to adequately suppress oil volatilization. Using a pressure that is too high can hinder the effectiveness of the vacuum process. Adherence to the specified range (300-500 Torr) is non-negotiable for achieving both safety and quality.

Overlooking Oil Degradation

Over time, quenching oil breaks down, especially when subjected to repeated high-heat cycles. Degraded oil has a lower flash point and produces more vapor. Failing to monitor oil quality and replace it as needed introduces a significant, and often overlooked, safety risk.

Making the Right Choice for Your Process

Applying these principles requires aligning your actions with your primary operational goals.

- If your primary focus is operator and facility safety: The non-negotiable first step is ensuring the integrity and proper function of the nitrogen backfill system to prevent the formation of a flammable atmosphere.

- If your primary focus is consistent product quality: Calibrating and maintaining the precise nitrogen pressure is critical, as this directly influences the oil's cooling performance and the final hardness of your workpiece.

- If your primary focus is equipment longevity and efficiency: Implementing a strict oil quality monitoring program and ensuring the nitrogen system works correctly will drastically reduce furnace pollution, minimizing downtime and maintenance costs.

Ultimately, a safe quenching process is an engineered outcome, not a matter of chance.

Summary Table:

| Safety Precaution | Purpose | Key Parameter |

|---|---|---|

| Nitrogen Backfill | Prevents oil vapor ignition by displacing oxygen | 300-500 Torr (0.4-0.67 x 10⁵ Pa) |

| Pressure Control | Suppresses violent oil volatilization while maintaining vacuum benefits | Maintain specified range |

| Oil Quality Monitoring | Prevents degradation that lowers flash point and increases vapor | Regular testing and replacement |

| Furnace Integrity Check | Ensures no oxygen leaks into the chamber | Leak testing and maintenance |

Optimize your quenching process for maximum safety and performance. KINTEK specializes in laboratory equipment and consumables, providing reliable solutions for vacuum furnaces and quenching systems. Our expertise ensures your operations meet the highest safety standards while achieving consistent metallurgical results. Contact us today to discuss how we can enhance your lab's safety and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why is a high vacuum furnace used for the homogenization of 3D-printed alloy libraries before corrosion testing? - FAQ

- What is the major advantage that brazing has over welding? Joining Dissimilar Metals with Ease

- What is the heating rate range for fast pyrolysis? Maximize Your Bio-Oil Yield

- How does an industrial vacuum drying oven contribute to the post-processing of gradient cathode material precursors?

- What is the temperature of pyrolysis? A Guide to Controlling Product Yields

- How does a laboratory vacuum drying oven contribute to the pretreatment of Super C65? Ensure Battery Stability

- What is the process of heat treatment furnace? Master the 3 Stages for Precise Material Properties

- What is the function of a vacuum drying oven in catalyst recovery? Maximize Cycle Life and Maintain Active Sites