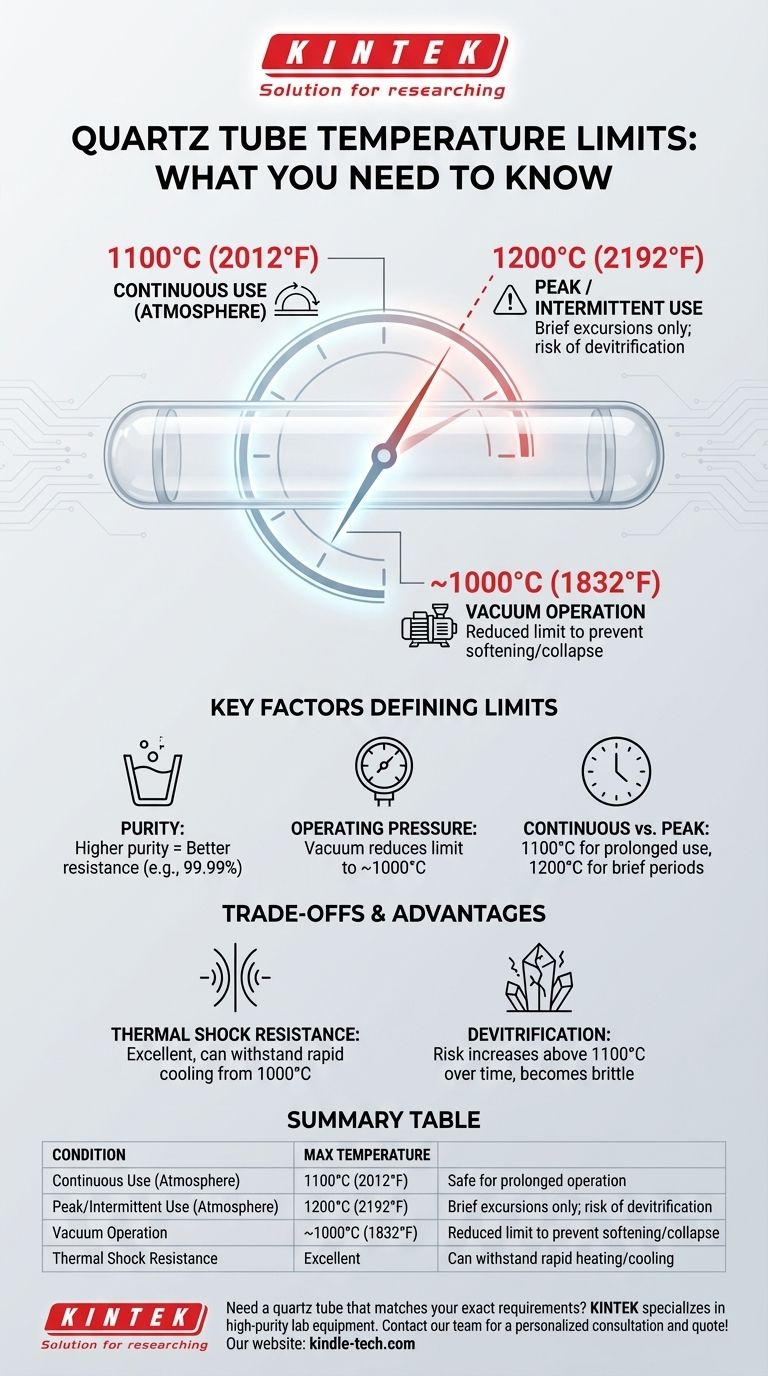

In practical terms, a standard transparent quartz tube can continuously withstand temperatures up to 1100°C (2012°F). However, its absolute maximum temperature can reach 1200°C (2192°F) under specific atmospheric conditions, while its performance is significantly altered by factors like purity and operating pressure.

The temperature a quartz tube can withstand is not a single number, but a variable dependent on its purity and the operating environment. Understanding the interplay between temperature, pressure, and thermal shock is critical for selecting the right tube and preventing failure.

The Key Factors Defining Temperature Limits

The advertised temperature rating is only a starting point. To use a quartz tube reliably and safely, you must understand the variables that dictate its real-world performance.

The Critical Role of Purity

A tube's temperature resistance is directly tied to its material purity. High-purity fused quartz (often 99.99%) has fewer contaminants that can act as nucleation sites for crystallization at high temperatures.

This superior purity allows the tube to maintain its structural integrity closer to its softening point, making it suitable for more demanding applications.

The Impact of Operating Pressure

The environment inside the tube drastically changes its temperature limits. A quartz tube can operate up to 1200°C at standard atmospheric pressure.

However, under a vacuum, the safe maximum operating temperature is reduced to approximately 1000°C. The lack of external pressure makes the material more susceptible to softening and deformation at elevated temperatures.

Continuous vs. Peak Temperature

It is essential to distinguish between continuous and peak use. The commonly cited 1100°C limit is a safe temperature for prolonged, continuous operation.

The 1200°C figure should be treated as a peak or intermittent limit. Pushing a tube to this temperature for extended periods increases the risk of structural failure or devitrification.

Exceptional Thermal Shock Resistance

One of quartz's most significant advantages is its extremely low coefficient of thermal expansion. This gives it remarkable resistance to thermal shock.

A quartz tube can be heated to 1000°C and then rapidly cooled to room temperature without cracking, a feat that would shatter most other ceramics.

Understanding the Critical Trade-offs

While powerful, quartz is not without its limitations. Acknowledging these trade-offs is key to successful implementation and avoiding costly failures.

The Temperature vs. Vacuum Constraint

You cannot have both maximum temperature and high vacuum simultaneously. If your process requires a vacuum, you must respect the lower 1000°C operating limit. Exceeding this under vacuum risks tube collapse.

The Risk of Devitrification

When held at high temperatures (especially above 1100°C) for extended periods, quartz can begin to devitrify. The amorphous glass structure converts back into a crystalline state (cristobalite).

This process makes the quartz opaque and, more importantly, mechanically weak and brittle. Devitrification is a primary failure mode in long-duration, high-temperature applications.

Purity vs. Cost

Higher performance comes at a price. The 99.99% pure quartz tubes that offer the best temperature resistance and optical clarity are significantly more expensive than standard-grade quartz. For less demanding applications, a lower-purity tube may be a more economical choice.

Making the Right Choice for Your Application

Use your specific operating goal to guide your selection and define your safety margins.

- If your primary focus is maximum temperature in atmosphere: Seek a high-purity quartz tube and plan for a continuous operating limit near 1100°C, reserving 1200°C for brief excursions.

- If your primary focus is high-temperature vacuum work: Acknowledge that the safe operating temperature is reduced to approximately 1000°C to prevent tube softening and ensure integrity.

- If your primary focus is applications with rapid heating and cooling: Quartz is an excellent choice due to its superior thermal shock resistance, providing reliability where other materials would fail.

By matching the tube's specifications to your specific operating conditions, you ensure both process reliability and safe operation.

Summary Table:

| Condition | Maximum Safe Temperature | Key Consideration |

|---|---|---|

| Continuous Use (Atmosphere) | 1100°C (2012°F) | Safe for prolonged operation |

| Peak/Intermittent Use (Atmosphere) | 1200°C (2192°F) | Brief excursions only; risk of devitrification |

| Vacuum Operation | ~1000°C (1832°F) | Reduced limit to prevent softening/collapse |

| Thermal Shock Resistance | Excellent (1000°C to room temp) | Can withstand rapid heating/cooling |

Need a quartz tube that matches your exact temperature and pressure requirements?

KINTEK specializes in high-purity lab equipment and consumables. Our experts can help you select the ideal quartz tube for your application, ensuring maximum temperature resistance, vacuum compatibility, and long-term reliability.

Contact our team today for a personalized consultation and quote!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- Why are polyethylene ball milling jars preferred over stainless steel for battery electrode materials?

- What is the maximum temperature for quartz windows? Ensure Long-Term Reliability and Avoid Devitrification

- What is the purpose of using graphite paper in hot press sintering? Protect Molds and Ensure Easy Sample Demolding

- Why are zirconia grinding jars and balls preferred for sulfide electrolytes? Ensure Purity & Battery Performance

- Why must a KEMS chamber have a turbomolecular pump? Ensure Ultra-High Vacuum for Precise Mass Spectrometry

- How can a gas ballast valve be used as a diagnostic tool? Identify Oil Contamination vs. System Leaks

- How do temperature control thermocouples and PID control cabinets influence the separation efficiency in crude magnesium vacuum distillation? Optimize Purity with Precise Thermal Control

- Why are zirconia grinding balls essential for LLZO production? Achieve High Purity in Solid-State Electrolyte Synthesis