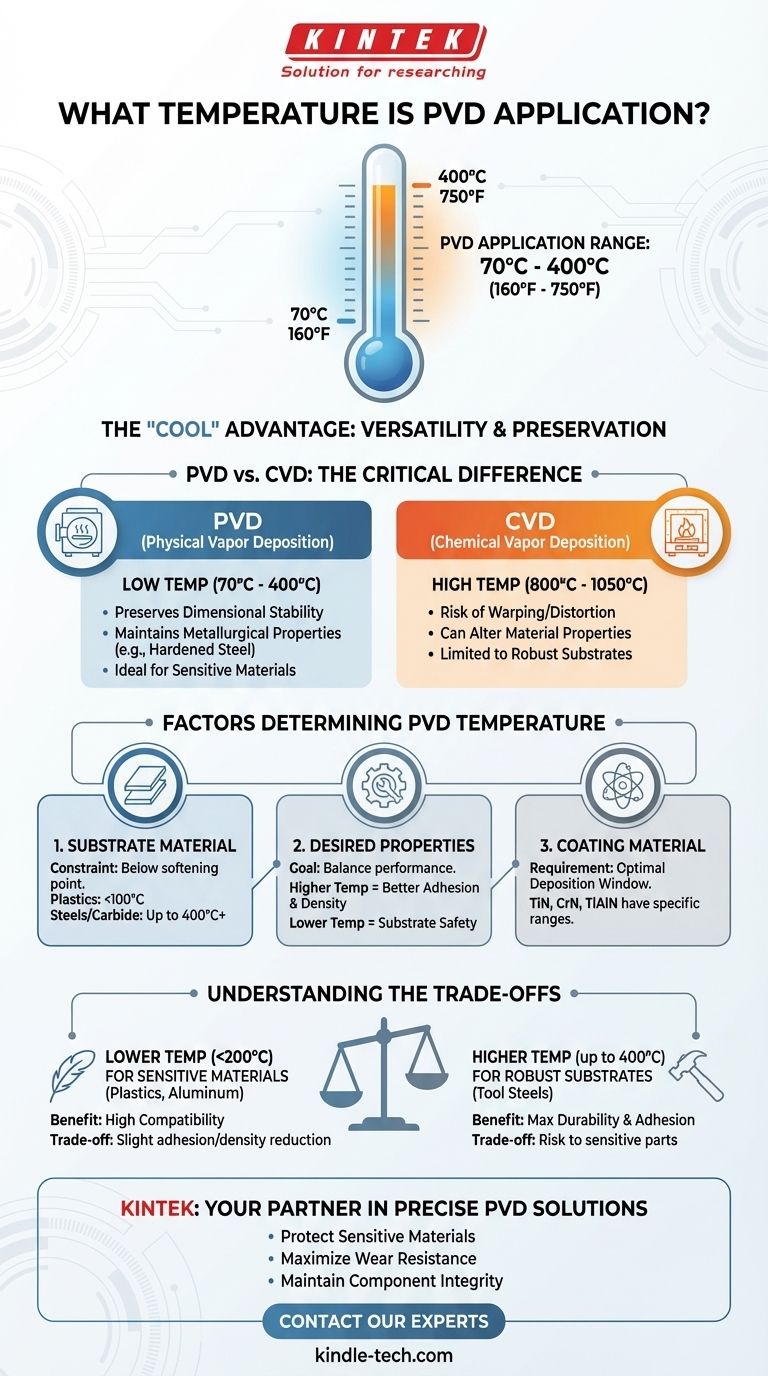

In physical vapor deposition (PVD) processes, the application temperature typically ranges from 70°C to 400°C (approximately 160°F to 750°F). This relatively low-temperature profile is a defining characteristic of PVD, allowing it to be used on a vast array of materials, from hardened steels to temperature-sensitive plastics, without damaging the underlying part.

The key takeaway is not a single temperature, but the versatility of the PVD process. Its "cool" nature, relative to other coating methods, is precisely what makes it a powerful solution for enhancing components without altering their fundamental material properties.

Why PVD is a "Low-Temperature" Process

The term "low temperature" is meaningful only in comparison. In the world of advanced coatings, PVD stands out for its ability to operate well below the critical thermal limits of most engineering materials.

The Critical Context: PVD vs. CVD

The primary alternative to PVD is Chemical Vapor Deposition (CVD). CVD processes typically require extremely high temperatures, often between 800°C and 1050°C (1475°F to 1925°F).

This fundamental difference is crucial. PVD deposits a solid coating material in a vacuum, while CVD relies on chemical reactions on the substrate surface at high heat.

Preserving Substrate Integrity

Operating at lower temperatures gives PVD a significant advantage. It ensures the dimensional stability of the component, preventing the warping or distortion that can occur at high heat.

Furthermore, it preserves the metallurgical properties of the substrate. For example, heat-treated tool steels maintain their carefully engineered hardness and temper, which would be destroyed by the extreme temperatures of a CVD process.

Factors That Determine PVD Process Temperature

The specific temperature used is not arbitrary; it is a carefully controlled parameter tailored to the application. Several factors dictate the optimal temperature for a given job.

The Substrate Material

This is the most critical constraint. The process temperature must remain below the point where the substrate material begins to soften, anneal, or deform.

- Plastics require the lowest temperatures, often below 100°C.

- Hardened steels and carbide can tolerate the higher end of the PVD range, up to 400°C or more, which helps promote better coating adhesion.

The Desired Coating Properties

Higher deposition temperatures generally lead to denser, more adherent coatings with superior wear resistance. The heat provides more energy to the depositing atoms, allowing them to arrange into a more ideal crystalline structure.

A balance must be struck between achieving the best possible coating properties and respecting the thermal limits of the part itself.

The Specific Coating Material

Different coating materials, such as Titanium Nitride (TiN), Chromium Nitride (CrN), or Titanium Aluminum Nitride (TiAlN), have different optimal deposition windows to achieve their target performance characteristics. The coating provider selects the temperature to optimize these properties.

Understanding the Trade-offs

Choosing a process temperature involves balancing performance goals with material limitations. There is no single "best" temperature, only the right temperature for a specific goal.

Lower Temperatures for Sensitive Materials

The primary benefit of using lower temperatures is compatibility. It opens the door for coating materials like aluminum, zinc, and polymers that cannot withstand high-heat processes.

The trade-off can sometimes be a slight reduction in coating adhesion or density compared to what could be achieved at higher temperatures on a more robust substrate.

Higher Temperatures for Maximum Performance

For substrates that can handle the heat (like tool steels), using the upper end of the PVD temperature range is preferable. The increased thermal energy improves atomic diffusion at the interface, creating a stronger bond between the coating and the substrate.

This results in maximum durability, hardness, and wear resistance, which is critical for demanding applications like cutting tools and industrial molds.

Making the Right Choice for Your Application

The process temperature is a variable that is tuned to achieve a specific outcome. To determine what is right for your project, consider your primary objective.

- If your primary focus is coating heat-sensitive materials (like plastics or tempered aluminum): A low-temperature PVD process (typically below 200°C) is required to prevent damage to the substrate.

- If your primary focus is maximum wear resistance on a robust substrate (like steel or carbide): A higher-temperature PVD process (e.g., 350°C - 400°C) will yield the best adhesion and coating structure.

- If you are coating a component with complex geometry or tight tolerances: A PVD process is ideal, as its low temperature prevents the distortion that high-heat methods could cause.

Understanding the role of temperature empowers you to work with your coating provider to select a process that enhances your component without compromising its core integrity.

Summary Table:

| Factor | Temperature Influence | Key Consideration |

|---|---|---|

| Substrate Material | Determines maximum safe temperature. | Plastics require <100°C; hardened steels can handle up to 400°C. |

| Coating Properties | Higher temps improve adhesion and density. | Balances performance with substrate limits. |

| Coating Material | Different materials have optimal deposition windows. | TiN, CrN, and TiAlN are tuned for specific results. |

Need a durable, precise PVD coating that won't compromise your component's integrity?

At KINTEK, we specialize in low-temperature PVD solutions for laboratories and manufacturers. Whether you are coating sensitive plastics, precision tool steels, or complex components, our expertise ensures optimal adhesion and performance without thermal damage.

We help you:

- Protect sensitive materials with our low-temperature (<200°C) processes.

- Maximize wear resistance on robust substrates using high-temperature (up to 400°C) techniques.

- Maintain dimensional stability and metallurgical properties of your parts.

Let's tailor a PVD coating process for your specific needs. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding