In short, modern muffle furnaces primarily use high-purity alumina or ceramic fiber insulation. Some specialized models, particularly those for very high temperatures or specific atmospheres, may use graphite felt. These materials are chosen for their exceptional ability to contain extreme heat, which is essential for the furnace's efficiency and temperature stability.

The choice of insulation is not arbitrary; it is a critical engineering decision directly tied to the furnace's maximum temperature, energy efficiency, and operational lifespan. Understanding the material—typically alumina fiber or graphite felt—tells you a great deal about the furnace's intended purpose and quality.

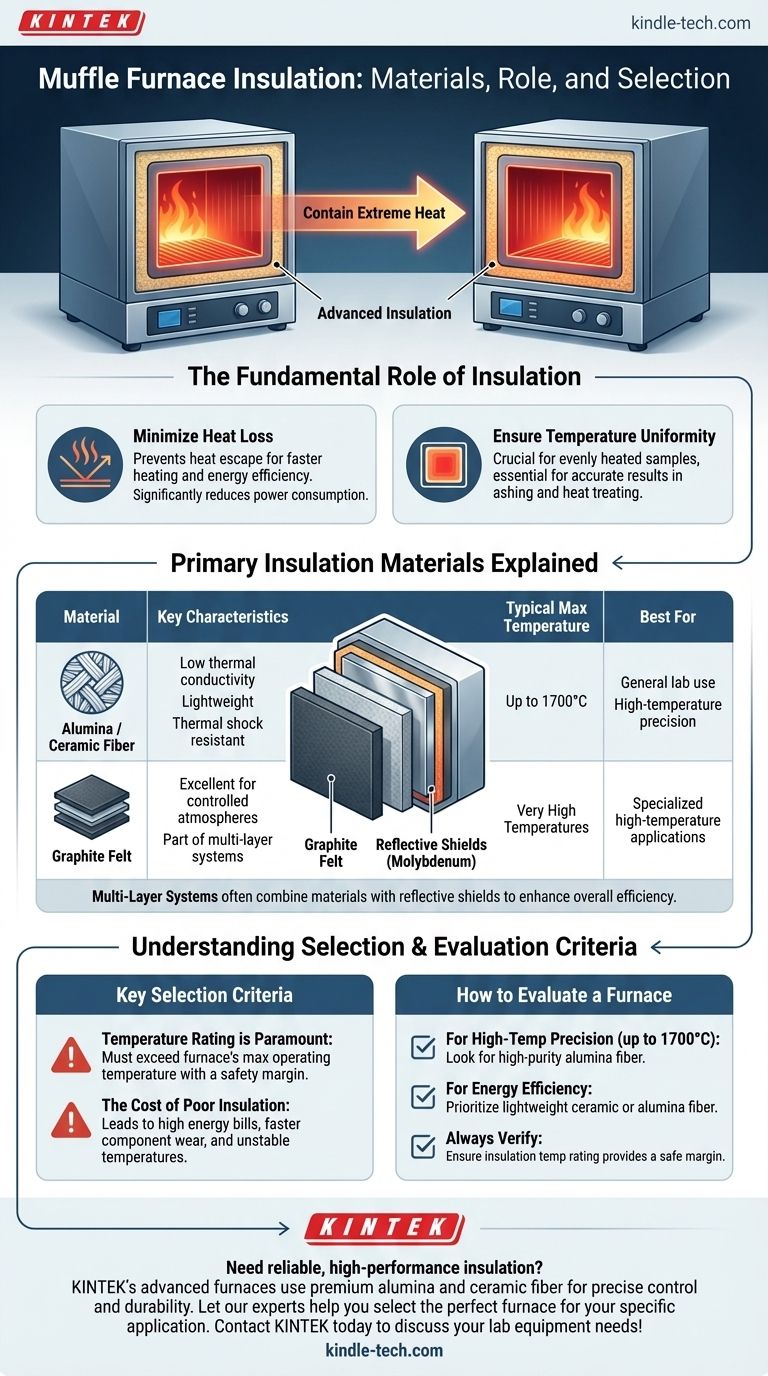

The Fundamental Role of Insulation

A muffle furnace's performance is defined by its ability to generate and maintain a precise, uniform temperature. The insulation is the key component that makes this possible.

To Minimize Heat Loss

The primary job of insulation is to keep the heat generated by the heating elements inside the furnace chamber.

By preventing heat from escaping, the furnace can reach its target temperature faster and use significantly less energy to maintain it.

To Ensure Temperature Uniformity

Effective insulation surrounds the heating chamber, ensuring that all surfaces are heated evenly.

This uniformity is critical for processes like ashing, heat treating, and materials testing, where consistent temperature across the entire sample is required for accurate results.

Primary Insulation Materials Explained

While older models used heavy firebricks, modern furnaces rely on advanced materials that offer superior performance in a lighter, more compact form.

Alumina and Ceramic Fibers

This is the most common type of insulation in modern laboratory and industrial muffle furnaces.

High-purity fibrous alumina is a synthetic material with extremely low thermal conductivity, meaning it's very poor at transferring heat. It is lightweight, resistant to thermal shock, and provides excellent electrical insulation at high temperatures, often rated for use up to 1700°C.

Graphite Felts

For certain high-temperature applications or furnaces with controlled atmospheres, graphite felt is the material of choice.

Graphite insulation can be used in soft or hard felt forms. It is often part of a sophisticated multi-layer system designed for extreme heat containment.

The Multi-Layer System

Insulation is often more than just a single layer of one material.

In some designs, it is an engineered system that may include an inner layer of graphite felt, reflective shields made of materials like molybdenum sheets, and an outer furnace body. The reflective shields bounce radiant heat back into the chamber, preventing it from even reaching the main insulation layer and improving overall efficiency.

Understanding the Key Selection Criteria

The quality and type of insulation directly impact the furnace's reliability and suitability for your work. Ignoring it can lead to poor performance and higher operational costs.

Temperature Rating is Paramount

The single most important factor is the material's maximum service temperature.

The insulation must be able to withstand a temperature significantly higher than the furnace's maximum operating temperature. This safety margin ensures the material does not degrade, which would compromise its insulating properties and shorten the furnace's lifespan.

The Cost of Poor Insulation

Inadequate or low-quality insulation will constantly leak heat into the surrounding environment.

This forces the heating elements to work harder and consume more power to maintain the set temperature, leading to higher energy bills and faster component wear. It also makes achieving a stable and uniform temperature much more difficult.

How to Evaluate a Furnace's Insulation

When selecting or assessing a muffle furnace, use the insulation type as a key indicator of its performance capabilities.

- If your primary focus is high-temperature precision (up to 1700°C): Look for furnaces explicitly specifying high-purity alumina fiber insulation, as this indicates a modern, high-performance design.

- If your primary focus is energy efficiency: Prioritize furnaces with lightweight ceramic or alumina fiber insulation, which are far superior to older, denser firebrick designs.

- If you are evaluating any furnace: Always verify that the insulation's maximum temperature rating provides a safe margin above the furnace's maximum operating temperature.

Understanding the insulation allows you to make a more informed decision, ensuring your equipment is perfectly matched to your technical requirements.

Summary Table:

| Insulation Material | Key Characteristics | Typical Max Temperature | Best For |

|---|---|---|---|

| Alumina/Ceramic Fiber | Low thermal conductivity, lightweight, thermal shock resistant | Up to 1700°C | General lab use, high-temperature precision |

| Graphite Felt | Excellent for controlled atmospheres, part of multi-layer systems | Very high temperatures | Specialized high-temperature applications |

Need a muffle furnace with reliable, high-performance insulation? KINTEK's advanced furnaces use premium alumina and ceramic fiber insulation to ensure precise temperature control, energy efficiency, and long-term durability for your laboratory. Let our experts help you select the perfect furnace for your specific application. Contact KINTEK today to discuss your lab equipment needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a muffle furnace and a normal furnace? Ensuring Sample Purity with Indirect Heating

- What is the difference between cold type and hot type? Uncover the Printing Revolution

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- What is melt loss? The Ultimate Guide to Reducing Metal Loss in High-Temp Processing

- What are the disadvantages of a muffle furnace? Understanding the Trade-offs for Your Lab