For most industrial PVD applications, the required base pressure is typically established in the high vacuum range, between 1x10⁻⁴ and 1x10⁻⁶ Torr. While some high-purity applications, like those in the semiconductor industry, demand ultra-high vacuum (UHV) levels below 10⁻⁸ Torr, the key is to create an environment clean enough for the specific film being deposited.

The primary goal of the vacuum in PVD is to remove unwanted gas molecules. This ensures that vaporized coating particles can travel from the source to the substrate without collisions or chemical reactions, which is essential for creating a pure, dense, and well-adhering thin film.

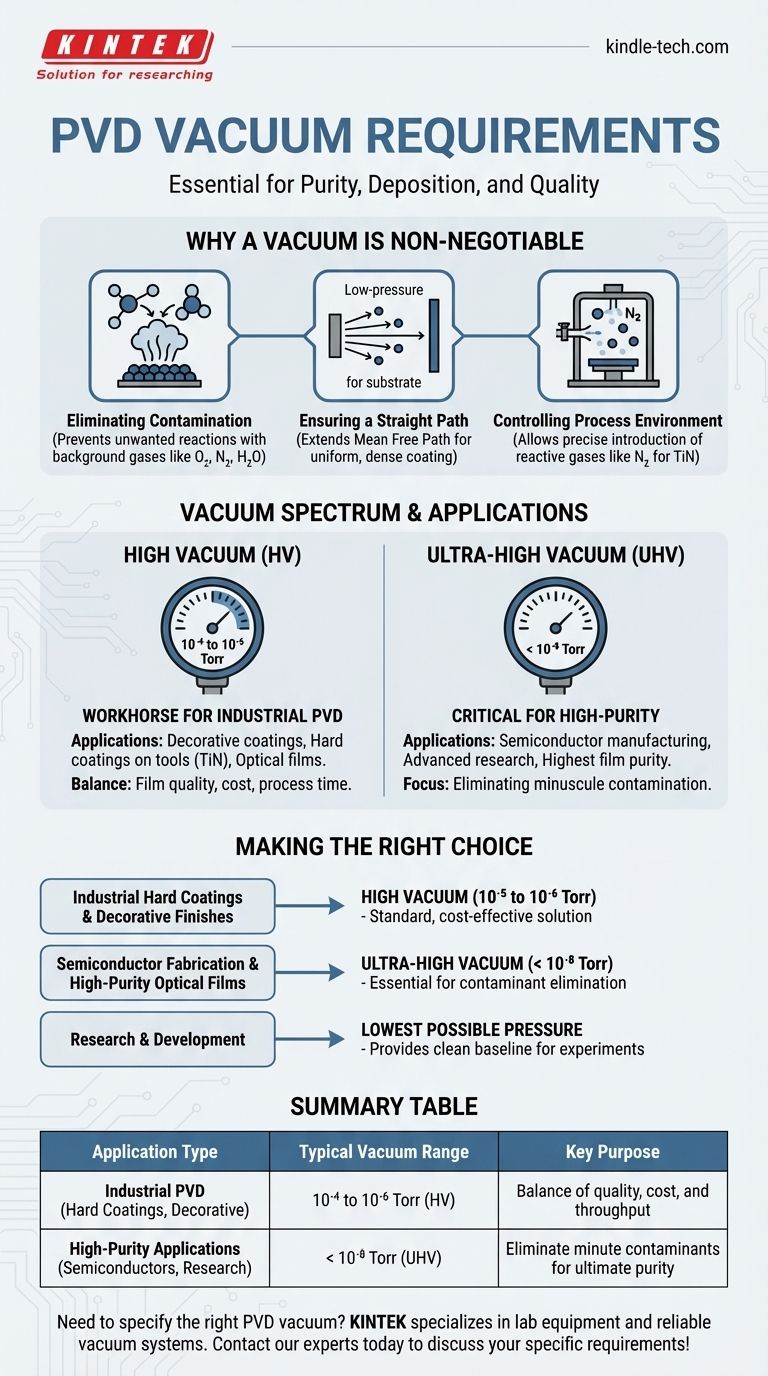

Why a Vacuum is Non-Negotiable in PVD

Achieving a low-pressure environment is the foundational step of any PVD process. The quality of the vacuum directly impacts the quality of the final coating.

Eliminating Contamination

At atmospheric pressure, a chamber is filled with reactive gases like oxygen, nitrogen, and water vapor. If these molecules are present during deposition, they will react with the vaporized material, creating unintended compounds (like oxides) and incorporating impurities into the film, degrading its performance.

Ensuring a Straight Path for Deposition

The most critical concept is the mean free path—the average distance a particle can travel before colliding with another. In a high vacuum, the mean free path is extended to be longer than the distance between the material source and the substrate.

This ensures the vaporized material travels in a straight, line-of-sight path, resulting in a uniform and dense coating. Without a vacuum, particles would scatter, leading to a porous, non-uniform, and poorly adhered film.

Controlling the Process Environment

Once a high vacuum base pressure is reached, all unwanted background gases have been removed. This creates a clean slate, allowing for the precise introduction of specific process gases if needed. For example, in reactive PVD, a controlled amount of nitrogen is introduced to form a titanium nitride (TiN) coating.

Different Vacuum Levels for Different Goals

The term "vacuum" isn't a single state; it's a spectrum of pressures. The required level depends entirely on the sensitivity of the application to impurities and the desired film properties.

High Vacuum (10⁻⁴ to 10⁻⁶ Torr)

This is the workhorse range for the vast majority of industrial PVD applications. It provides a sufficiently clean environment for decorative coatings, hard coatings on tools (e.g., TiN), and many optical films. It offers an excellent balance between film quality, cost, and process time.

Ultra-High Vacuum (UHV) (10⁻⁸ Torr and Lower)

UHV is required for applications where even minuscule levels of contamination can cause device failure. This is the domain of semiconductor manufacturing, advanced research, and applications requiring the highest possible film purity and density.

Understanding the Trade-offs

Choosing a target vacuum level is a critical decision that balances technical requirements with practical constraints.

Purity vs. Cost and Complexity

Achieving lower pressures requires more advanced and expensive equipment, such as turbomolecular or cryogenic pumps instead of simpler diffusion pumps. The chamber design and materials must also be more robust to prevent leaks and outgassing, significantly increasing capital costs.

Quality vs. Throughput

Pumping a chamber down to UHV takes substantially longer than reaching a standard high vacuum. This extended cycle time reduces the number of batches that can be processed, directly impacting manufacturing throughput. The cost of a higher-quality film is often a longer process time.

Making the Right Choice for Your Goal

Your target vacuum level should be driven by the non-negotiable requirements of your final product.

- If your primary focus is industrial hard coatings or decorative finishes: A high vacuum in the 10⁻⁵ to 10⁻⁶ Torr range is the standard and most cost-effective solution.

- If your primary focus is semiconductor fabrication or high-purity optical films: An ultra-high vacuum (UHV) system capable of reaching 10⁻⁸ Torr or lower is necessary to eliminate contaminants.

- If your primary focus is research and development: Your system should be capable of reaching the lowest possible pressure to provide a clean baseline for a wide range of experiments.

Ultimately, the vacuum level must be good enough to ensure the mean free path exceeds the chamber dimensions and residual gas contamination is below the tolerance of your specific process.

Summary Table:

| Application Type | Typical Vacuum Range | Key Purpose |

|---|---|---|

| Industrial PVD (Hard Coatings, Decorative) | 10⁻⁴ to 10⁻⁶ Torr (High Vacuum) | Balance of quality, cost, and throughput |

| High-Purity Applications (Semiconductors, Research) | < 10⁻⁸ Torr (Ultra-High Vacuum) | Eliminate minute contaminants for ultimate purity |

Need to specify the right PVD vacuum for your application? KINTEK specializes in lab equipment and consumables, providing the expertise and reliable vacuum systems essential for successful thin-film deposition. Whether you're developing industrial coatings or high-purity semiconductor layers, we can help you achieve the perfect process environment. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

People Also Ask

- What types of gases can a water circulating vacuum pump handle? Safely Manage Flammable, Condensable & Dirty Gases

- What are the advantages of a water circulating vacuum pump? Superior Durability for Demanding Lab Environments

- What determines the vacuum degree achievable by a water circulating vacuum pump? Unlock the Physics of Its Limits

- How does the impeller rotation affect the gas flow in a water circulating vacuum pump? A Guide to the Liquid Ring Principle

- How does a water circulating vacuum pump operate? Discover the Efficient Liquid Piston Principle