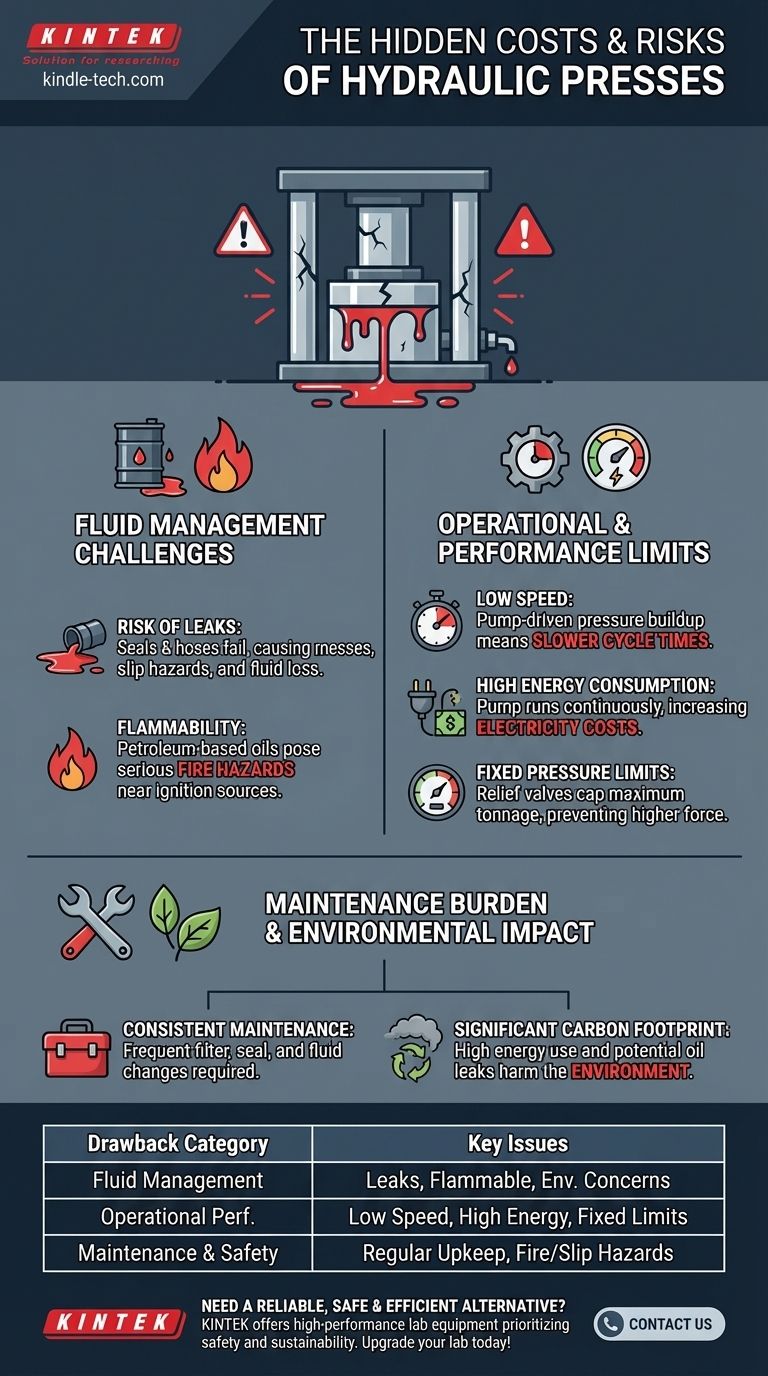

While incredibly powerful, the hydraulic press is not without significant operational and safety drawbacks. Its core problems revolve around the fluid that gives it power, leading to potential leaks, safety hazards, and high maintenance needs. Furthermore, they are often characterized by low operational speeds and high energy consumption compared to alternatives.

The immense force of a hydraulic press comes at a cost. Its reliance on pressurized fluid introduces complexities in maintenance, safety, and operational efficiency that must be carefully managed.

The Challenge of Managing Hydraulic Fluid

The defining component of a hydraulic press—its fluid—is also the source of its most common problems.

The Risk of Leaks

Hydraulic systems are prone to fluid leakage from seals, hoses, or fittings. A leak not only causes the press to lose pressure and function improperly but also creates a significant cleanup task and a potential slip hazard on the shop floor.

These leaks represent a direct loss of operational fluid, increasing costs over time and posing an environmental risk if not properly contained.

Flammability and Safety Concerns

Many standard hydraulic oils are petroleum-based and therefore flammable. A leak near an ignition source, such as a spark from other machinery or a welding operation, can create a serious fire hazard.

While fire-resistant fluids are available, they often come at a higher cost or with their own performance trade-offs.

Operational and Performance Limitations

Beyond fluid management, the fundamental design of a hydraulic press imposes certain limits on its performance and efficiency.

Low Operational Speed

Hydraulic presses are generally slower than their mechanical counterparts. The ram's movement depends on a pump moving a large volume of fluid to build pressure, which takes time. This can make them less suitable for high-speed, high-volume production lines.

High Energy Consumption

To maintain readiness, the hydraulic pump often runs continuously to keep the system pressurized, even when the press is idle between cycles. This leads to significant energy consumption and electricity costs, especially when compared to mechanical presses that only draw significant power during the stroke itself.

Fixed Pressure Limits

A hydraulic system is protected by a pressure relief valve. While this is a critical safety feature, it means the press has a definitive maximum force that cannot be exceeded. Once this pressure is reached, the valve diverts fluid, capping the available tonnage.

Understanding the Trade-offs

The choice to use a hydraulic press involves accepting a series of trade-offs between power, precision, and operational overhead.

The Burden of Maintenance

Hydraulic systems require consistent and thorough maintenance. Hoses, seals, and pumps are wear items that must be inspected and replaced regularly to prevent failure. The hydraulic fluid itself must be filtered and periodically replaced to avoid contamination that can damage internal components.

The Environmental Footprint

Between the high energy consumption of the pump and the potential for oil leaks into the environment, hydraulic presses carry a notable carbon footprint. This is an increasing concern for businesses focused on sustainability and responsible operations.

Making the Right Choice for Your Application

Understanding these drawbacks is key to selecting the right tool for your specific manufacturing or fabrication goal.

- If your primary focus is raw power and force control: The hydraulic press is superior for applications requiring immense, sustained force, such as forging or deep-drawing, provided you budget for its maintenance.

- If your primary focus is high speed and production volume: A mechanical press is often a more efficient and cost-effective choice for repetitive stamping or punching operations.

- If your primary focus is safety and environmental impact: Mitigate the risks by investing in a modern, energy-efficient system and using non-flammable, biodegradable hydraulic fluids.

By weighing these inherent limitations against its unique strengths, you can deploy a hydraulic press effectively and safely.

Summary Table:

| Drawback Category | Key Issues |

|---|---|

| Fluid Management | Risk of leaks, flammable oil, environmental concerns |

| Operational Performance | Low speed, high energy use, fixed pressure limits |

| Maintenance & Safety | Regular upkeep needed, potential fire hazards, slip risks |

Need a reliable alternative for your lab or production line? KINTEK specializes in high-performance lab equipment and consumables, offering solutions that prioritize safety, efficiency, and sustainability. Whether you're upgrading from a hydraulic system or seeking a more efficient press for your laboratory needs, our experts can help you find the right equipment. Contact us today to discuss how we can enhance your operational safety and reduce maintenance costs!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the Bernoulli's principle of hydraulic press? It's Actually Pascal's Law That Powers It

- How many pounds of force can a hydraulic press produce? From 10,000 to 80,000+ Tons Explained

- What is a hydraulic press made of? Discover the Core Components for Immense Force

- How do you make a pellet sample? A 4-Step Guide to Perfect Pressed Pellets for Accurate Analysis

- Why KBr is used in the KBr pellet method? The Ideal Matrix for Clear IR Spectroscopy

- Why is a laboratory hydraulic press used for pelletizing metal oxide powders? Unlock Precise Gas-Sensing Data

- What are the characteristics and uses of a belt press in the HPHT process? Mastery of Industrial Diamond Synthesis

- How do you make biomass pellets at home? A Step-by-Step Guide to DIY Fuel Production