To be clear, ceramics are used extensively throughout the human body in applications demanding high strength, wear resistance, and biological compatibility. You will find them most commonly in orthopedic joint replacements, dental implants and crowns, and as materials to repair or replace bone, leveraging their unique ability to perform for decades within the demanding biological environment.

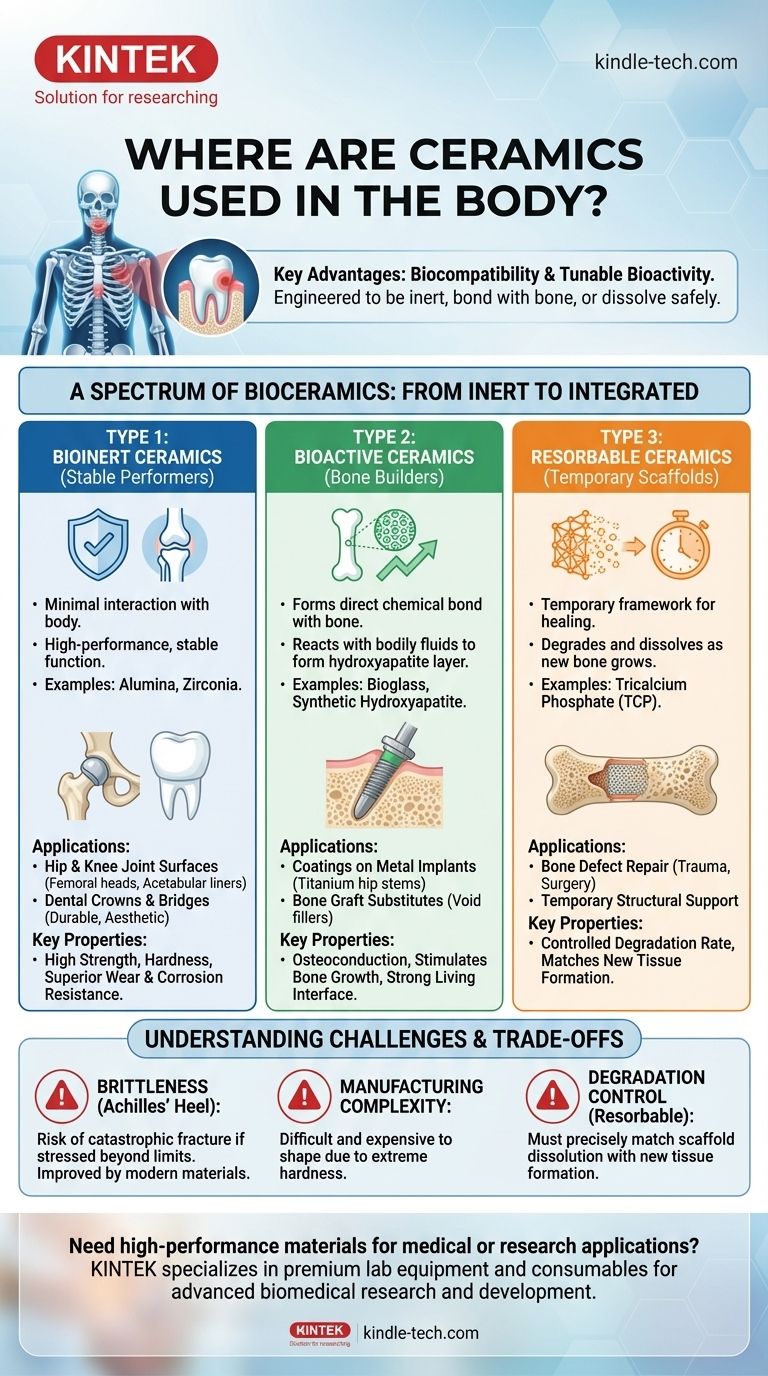

The central reason for using ceramics in the body is their unique combination of biocompatibility and tunable bioactivity. Unlike metals or polymers, ceramics can be engineered to be completely inert, to actively bond with bone, or to dissolve safely as new tissue grows, making them exceptionally versatile for medical implants.

The Core Properties Driving Ceramic Use

The selection of any material for medical use is governed by a strict set of requirements. Ceramics excel in several key areas that make them uniquely suited for implantation.

Biocompatibility: The Foundation of Medical Use

Biocompatibility is the most critical property. It means the material does not provoke a significant adverse immune response from the body, such as chronic inflammation or rejection.

Ceramics, particularly materials like zirconia and alumina, are highly stable and release virtually no ions into the body, making them exceptionally biocompatible and safe for long-term use.

Mechanical Strength and Hardness

Many medical applications, especially orthopedic ones, are load-bearing. Implants must withstand the immense and repetitive forces of daily human activity.

Ceramics possess very high compressive strength and hardness. This makes them incredibly resistant to being crushed or scratched, which is vital for the surfaces of a hip or knee joint that rub against each other millions of times.

Superior Wear and Corrosion Resistance

The human body is a corrosive environment. Metals can corrode over time, releasing ions that may cause adverse reactions. Polymers can degrade and shed wear particles that lead to inflammation.

Ceramics are chemically inert and extremely resistant to both corrosion and wear. This longevity ensures the implant remains functional and safe for decades, minimizing the need for revision surgeries.

A Spectrum of Bioceramics: From Inert to Integrated

Not all bioceramics are the same. They are classified based on how they interact with the surrounding biological tissue, falling into three main categories.

Type 1: Bioinert Ceramics (The Stable Performers)

These materials are designed to have minimal interaction with the body. Their goal is to provide a stable, high-performance function without chemically reacting with tissue.

The most common examples are alumina (aluminum oxide) and zirconia (zirconium dioxide). They are primarily used for the ball-and-socket components (femoral heads and acetabular liners) in hip replacements and for durable, aesthetic dental crowns and bridges.

Type 2: Bioactive Ceramics (The Bone Builders)

Bioactive ceramics are designed to form a direct chemical bond with bone. When implanted, their surface reacts with bodily fluids to form a layer of hydroxyapatite (HA), the same mineral that makes up our bones.

This encourages bone cells to attach and grow directly onto the implant surface, creating a strong, living interface. Bioglass and synthetic hydroxyapatite are key examples, often used as coatings on metal implants (like titanium hip stems) or as bone graft substitutes to fill voids.

Type 3: Resorbable Ceramics (The Temporary Scaffolds)

These ceramics serve as a temporary framework, or scaffold, for the body to heal itself. They are designed to degrade and dissolve at a controlled rate while being slowly replaced by new, natural bone.

Materials like tricalcium phosphate (TCP) are commonly used for this purpose. They are ideal for repairing bone defects from trauma or surgery where the body has the capacity to regenerate but needs structural support during the process.

Key Applications Across Medical Fields

Building on these properties, bioceramics have become indispensable in several areas of medicine.

Orthopedics: Rebuilding Joints and Bones

This is the largest application area. Ceramic components are used in total hip and knee replacements due to their low friction and incredibly low wear rates, which dramatically reduce the risk of implant loosening over time. They are also used as bone void fillers and in spinal fusion devices.

Dentistry: Restoring Form and Function

The strength, biocompatibility, and tooth-like appearance of ceramics make them a cornerstone of modern dentistry. Zirconia and other dental ceramics are used for implants, crowns, bridges, and veneers, offering a durable and highly aesthetic solution for tooth replacement.

Emerging and Specialized Uses

Research continues to expand the use of ceramics. They are being explored for components in heart valves, as carriers for targeted drug delivery, and in brachytherapy as capsules for radioactive seeds used to treat cancer.

Understanding the Trade-offs and Challenges

Despite their advantages, ceramics are not a perfect solution for every application. It is crucial to understand their limitations.

Brittleness: The Achilles' Heel

The primary drawback of ceramics is their brittleness. Unlike metals, which can bend or deform under extreme stress (ductility), a ceramic will fracture catastrophically if its structural limit is exceeded.

While modern medical-grade ceramics like zirconia have significantly improved toughness, the risk of fracture, though small, remains a critical design consideration.

Manufacturing and Machining Complexity

The extreme hardness that makes ceramics so wear-resistant also makes them very difficult and expensive to manufacture and shape into complex geometries. This can increase the cost of ceramic implants compared to their metal or polymer counterparts.

Degradation Control

For resorbable ceramics, the primary challenge is precisely matching the material's degradation rate to the rate of new tissue formation. If the scaffold dissolves too quickly, the new tissue lacks support; if it dissolves too slowly, it can impede full healing.

Matching the Ceramic to the Clinical Goal

The choice of ceramic is dictated entirely by the desired biological outcome.

- If your primary focus is long-term structural stability with minimal biological interaction: Choose a high-strength, bioinert ceramic like zirconia or alumina for applications like joint bearing surfaces or dental crowns.

- If your primary focus is to stimulate and integrate with new bone growth: Use a bioactive ceramic like hydroxyapatite or bioglass, typically as a coating on a structural metal implant or as a bone graft.

- If your primary focus is to provide a temporary scaffold that is eventually replaced by the body: Select a resorbable ceramic like tricalcium phosphate to fill a bone defect that can heal on its own.

Ultimately, the sophisticated use of these materials allows clinicians to not only replace what is lost but to work with the body to heal and regenerate.

Summary Table:

| Ceramic Type | Key Properties | Primary Medical Applications |

|---|---|---|

| Bioinert (e.g., Zirconia, Alumina) | High strength, wear resistance, biocompatibility | Hip/knee joint surfaces, dental crowns & bridges |

| Bioactive (e.g., Hydroxyapatite, Bioglass) | Bonds directly with bone (osteoconduction) | Coatings on metal implants, bone graft substitutes |

| Resorbable (e.g., Tricalcium Phosphate) | Degrades at a controlled rate as new bone forms | Temporary scaffolds for bone defect repair |

Need high-performance materials for your medical or research applications? KINTEK specializes in premium lab equipment and consumables, including materials for advanced biomedical research and development. Our expertise can help you source the right components for developing or testing the next generation of bioceramic implants. Contact our experts today to discuss how we can support your laboratory's innovation in medical materials.

Visual Guide

Related Products

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- Does silicon carbide dissolve in water? Discover Its Unmatched Chemical Stability

- Which process parameters were analyzed in the grinding of AlSiTi? Optimize Ceramic Machining Efficiency

- Which is harder silicon carbide or tungsten carbide? Discover the Key to Material Selection

- Why is a hexagonal Boron Nitride (h-BN) layer required for LATP? Protect Your Samples from Carbon Contamination

- How hot can you heat ceramic? From Pottery to 2700°C with Advanced Materials

- Why are alumina ceramic discs used as sample supports? Optimize Cathodic Cage Deposition Efficiency

- Can ceramics withstand high temperatures? Discover Their Exceptional Heat Resistance

- What are the 4 main classes of ceramic materials? A Guide to Their Functions and Applications