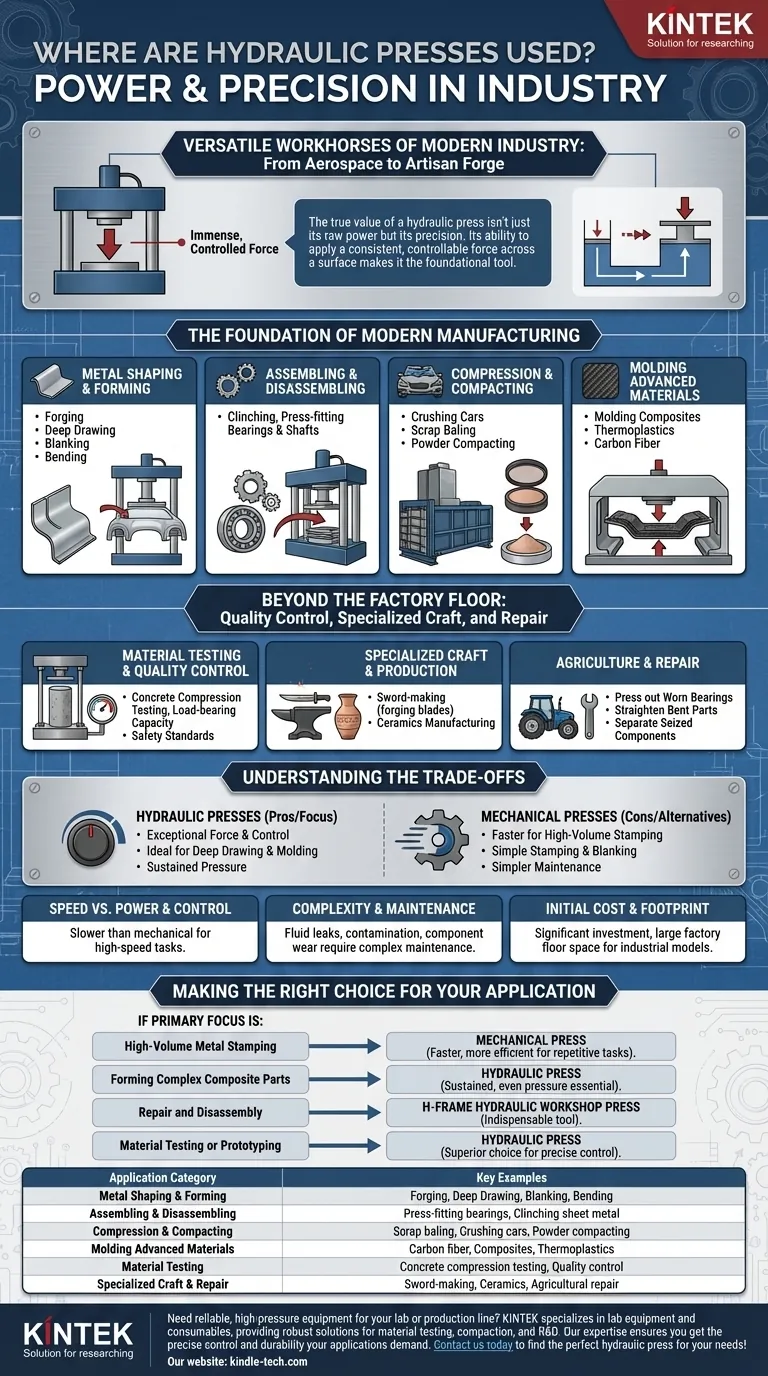

At its core, a hydraulic press is used wherever immense, controlled force is needed to shape, assemble, crush, or test materials. They are the versatile workhorses of modern industry, found in everything from massive automotive and aerospace manufacturing plants to specialized sword-making forges and agricultural repair shops.

The true value of a hydraulic press isn't just its raw power but its precision. Its ability to apply a consistent, controllable force across a surface makes it the foundational tool for forming everything from car doors and carbon fiber components to compacting powders and testing the strength of concrete.

The Foundation of Modern Manufacturing

The versatility of the hydraulic press stems from its simple and effective principle: applying Pascal's law to multiply force. This allows it to perform a wide range of essential manufacturing operations with a high degree of control.

Metal Shaping and Forming

This is the most common application, where presses permanently alter the shape of metal sheets or blocks. Key operations include forging (shaping metal with compressive force), deep drawing (stretching sheet metal into a die), blanking (punching out shapes), and bending.

Assembling and Disassembling Components

Immense force is often required to join parts together or take them apart. A hydraulic press is used for clinching (joining sheet metals without welding) and press-fitting components like bearings and shafts into place, a common task in automotive and equipment repair.

Compression and Compacting

This category involves reducing the volume of a material. The most visually dramatic example is crushing cars for recycling, but it also includes scrap baling, compacting cosmetic powders, and even producing fat-free cocoa powder by pressing the fat from cocoa beans.

Molding Advanced Materials

Modern manufacturing relies on materials beyond metal. Hydraulic presses are critical for molding composites, thermoplastics, and carbon fiber components, especially in the aerospace and high-performance automotive industries where strength and light weight are paramount. The sustained pressure is essential for curing these materials correctly.

Beyond the Factory Floor

While central to large-scale manufacturing, the applications of hydraulic presses extend into quality control, specialized crafts, and essential repair work.

Material Testing and Quality Control

In construction and material science, hydraulic presses are used for destructive testing. A prime example is concrete compression testing, where a press determines the load-bearing capacity of a concrete cylinder, ensuring it meets safety standards.

Specialized Craft and Production

Artisans and specialized manufacturers rely on the controlled power of hydraulic presses. This includes traditional sword-making, where presses help forge and shape the blade, and ceramics manufacturing, where they are used to compact ceramic powders into a desired form before firing.

Agriculture and Repair

On a more practical, everyday level, hydraulic presses are indispensable in agricultural and mechanical repair shops. They are used to press out worn bearings from farm equipment, straighten bent parts, and separate rusted components that are otherwise seized together.

Understanding the Trade-offs

While incredibly versatile, hydraulic presses are not the universal solution for every task. Understanding their limitations is key to appreciating where they excel.

Speed vs. Power and Control

Hydraulic presses deliver exceptional force and control over the entire stroke, which is ideal for deep drawing and molding. However, they are generally slower than their mechanical press counterparts, which are often preferred for high-speed, high-volume operations like simple stamping or blanking.

Complexity and Maintenance

A hydraulic system relies on fluid, pumps, hoses, and seals. This introduces the potential for fluid leaks, contamination, and component wear, requiring a different and sometimes more complex maintenance routine compared to a simpler mechanical system.

Initial Cost and Footprint

While smaller workshop presses can be relatively affordable, large-scale industrial hydraulic presses represent a significant investment in both capital and factory floor space. Their power and size are directly related to their cost.

Making the Right Choice for Your Application

The decision to use a hydraulic press depends entirely on the specific force, control, and material requirements of the task.

- If your primary focus is high-volume metal stamping: A mechanical press is often faster and more efficient for simple, repetitive tasks.

- If your primary focus is forming complex composite parts: The sustained, even pressure of a hydraulic press is essential for curing materials like carbon fiber.

- If your primary focus is repair and disassembly: A smaller H-frame hydraulic workshop press is an indispensable tool for pressing bearings and straightening shafts.

- If your primary focus is material testing or prototyping: The precise control over pressure and stroke makes a hydraulic press the superior choice for lab work.

Ultimately, where immense and controllable force is needed to shape, test, or assemble our world, the hydraulic press remains the fundamental tool for the job.

Summary Table:

| Application Category | Key Examples |

|---|---|

| Metal Shaping & Forming | Forging, Deep Drawing, Blanking, Bending |

| Assembling & Disassembling | Press-fitting bearings, Clinching sheet metal |

| Compression & Compacting | Scrap baling, Crushing cars, Powder compacting |

| Molding Advanced Materials | Carbon fiber, Composites, Thermoplastics |

| Material Testing | Concrete compression testing, Quality control |

| Specialized Craft & Repair | Sword-making, Ceramics, Agricultural equipment repair |

Need reliable, high-pressure equipment for your lab or production line? KINTEK specializes in lab equipment and consumables, providing robust solutions for material testing, compaction, and R&D. Our expertise ensures you get the precise control and durability your applications demand. Contact us today to find the perfect hydraulic press for your needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples