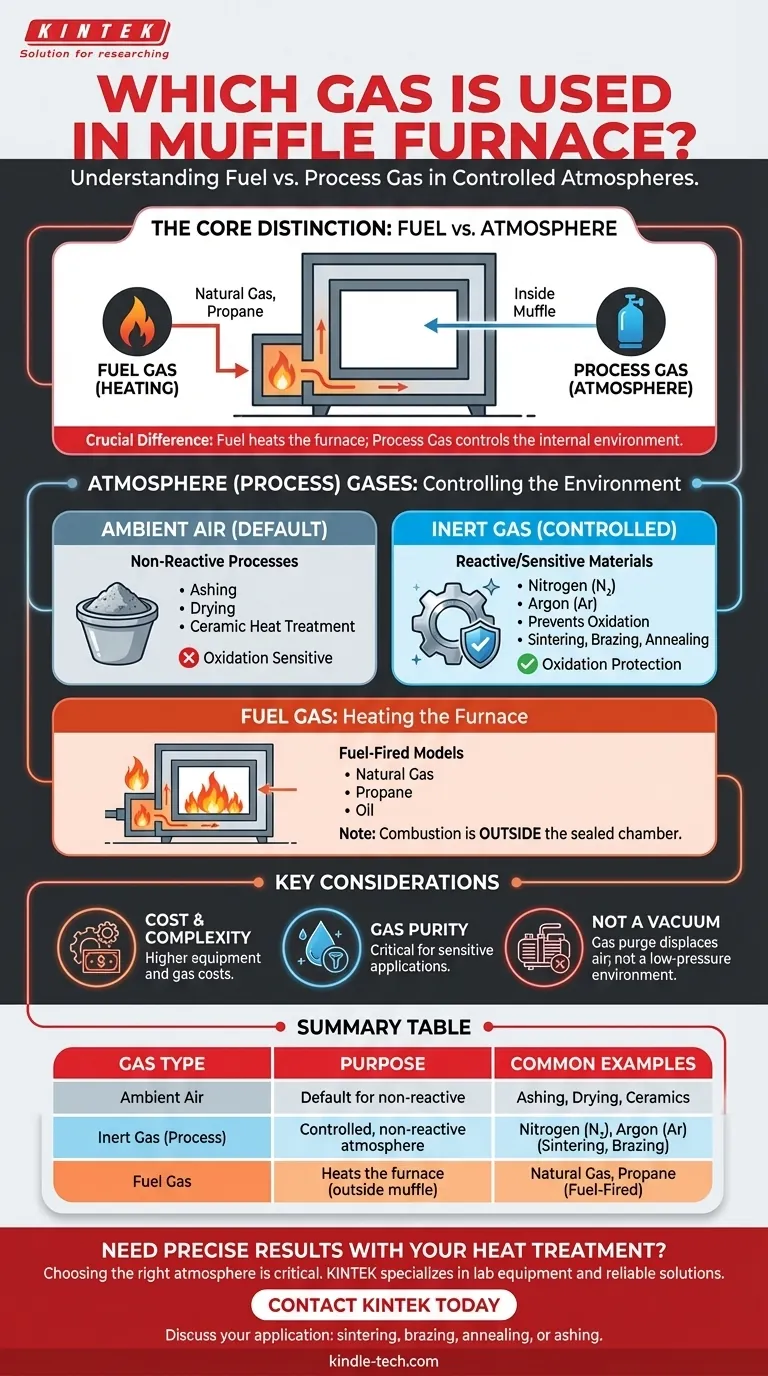

The type of gas used in a muffle furnace depends entirely on its function—whether it is for heating the furnace itself or for creating a controlled atmosphere inside it. For furnaces heated by combustion, the fuel is typically natural gas or propane. For creating a specific chemical environment to protect the material being heated, the most common gases are inert ones like nitrogen and argon.

A standard muffle furnace simply operates in ambient air. The need for a specific gas, such as nitrogen or argon, arises only when the process requires a controlled, non-reactive atmosphere to prevent outcomes like oxidation.

The Default Environment: Ambient Air

A muffle furnace is fundamentally a high-temperature oven with a sealed inner chamber (the "muffle") that isolates the sample from the heating elements. This design ensures clean, uniform heating.

Why Air is Often Sufficient

For many common applications, the default atmosphere of ambient air inside the chamber is perfectly acceptable. This includes processes like determining the ash content of a sample, drying materials, or heat-treating ceramics and other non-reactive substances.

The Role of the Muffle

The key feature is the muffle itself, typically made of ceramic. It prevents direct contact between the heating elements and the sample. This separation protects the sample from contamination and ensures that heat is transferred evenly through radiation.

When a Controlled Atmosphere is Necessary

For processes involving materials that react with oxygen at high temperatures, controlling the atmosphere inside the muffle is critical. This is where specialized gases are introduced.

Preventing Oxidation and Contamination

The primary reason to use a process gas is to displace the oxygen from the ambient air. At high temperatures, oxygen will rapidly oxidize most metals, forming a layer of scale or rust that can ruin the component. An inert atmosphere prevents this.

Common Protective Gases

Nitrogen (N₂) and Argon (Ar) are the most common choices for creating a protective, or inert, atmosphere. They are chemically stable and do not react with the materials being heated, even at extreme temperatures. This is essential for applications like brazing, sintering, and annealing sensitive metals.

How It Works in Practice

In an atmosphere-controlled furnace, the inert gas is fed from a supply tank into the muffle chamber. The gas purges the chamber, pushing the ambient air out through a dedicated release hole or vent. This creates a low-oxygen environment to protect the workpiece.

Distinguishing Fuel Gas from Process Gas

It is crucial to differentiate between the gas used to heat the furnace and the gas used to control the internal atmosphere.

Fuel for Heating

Some industrial muffle furnaces are fuel-fired, meaning they generate heat by burning a combustible gas like natural gas, propane, or oil. This combustion occurs outside the sealed muffle chamber, heating it from the exterior.

Atmosphere for Processing

Process gases, like nitrogen and argon, are used inside the muffle chamber. Their purpose is purely chemical—to create a specific environment for the material—not to generate heat.

Electric vs. Fuel-Fired Furnaces

Many laboratory and modern industrial muffle furnaces are electrically heated. In these models, the concept of a fuel gas is irrelevant. The only gas consideration is whether a controlled atmosphere is needed for the process itself.

Understanding the Trade-offs

Choosing to use a controlled atmosphere introduces new considerations that are important to understand.

Cost and Complexity

A furnace designed for controlled atmospheres is more complex and expensive than a standard air furnace. It requires additional components like gas lines, flow meters, and regulators, along with the ongoing cost of the gas itself.

Gas Purity Requirements

For highly sensitive metallurgical or electronic applications, the purity of the inert gas can be critical. Trace amounts of oxygen or moisture in the gas supply can sometimes be enough to compromise the process.

Not a True Vacuum

Creating an inert atmosphere by purging with gas is not the same as creating a vacuum. While it effectively removes most of the oxygen, a low-pressure environment may be required for certain advanced processes, which would necessitate a vacuum furnace instead.

Making the Right Choice for Your Application

Your choice depends directly on the material you are processing and your desired outcome.

- If your primary focus is ashing, drying, or heat-treating non-reactive materials: A standard furnace operating in ambient air is typically all you need.

- If your primary focus is brazing, sintering, or annealing metals sensitive to oxidation: You require a furnace capable of using an inert gas atmosphere, such as nitrogen or argon.

- If you are operating a fuel-fired furnace: The fuel will be a combustible gas like natural gas, which is entirely separate from any process gas used inside the muffle.

Ultimately, selecting the right gas is about controlling the chemical environment to achieve the precise material properties you require.

Summary Table:

| Gas Type | Purpose | Common Examples |

|---|---|---|

| Ambient Air | Default atmosphere for non-reactive processes | Ashing, drying, ceramic heat treatment |

| Inert Gas (Process) | Creates a controlled, non-reactive atmosphere | Nitrogen (N₂), Argon (Ar) for sintering, brazing |

| Fuel Gas | Heats the furnace (combustion occurs outside muffle) | Natural gas, Propane (in fuel-fired furnaces) |

Need to achieve precise results with your heat treatment processes?

Choosing the right furnace atmosphere is critical for success. KINTEK specializes in lab equipment and consumables, providing the expertise and reliable equipment—from standard muffle furnaces to advanced atmosphere-controlled models—to meet your specific laboratory needs.

Contact us today to discuss your application and ensure you have the right solution for sintering, brazing, annealing, or ashing.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between a muffle furnace and a chamber furnace? Understand the Key Distinctions for Your Lab

- What is the maximum temperature of muffle furnace? A Guide from 1100°C to 1800°C

- What is the purpose of a muffle furnace in a lab? Achieve Pure, High-Temperature Heat for Your Materials

- What is the difference between hot air oven and muffle furnace? Choose the Right Tool for Your Lab's Thermal Needs

- What is the main function of the muffle furnace? Achieve Pure, High-Temperature Heating Without Contamination