The short answer is neither is universally "better." The choice between a pneumatic and a hydraulic press depends entirely on your application's primary requirement: speed or force. Hydraulic presses are the definitive choice for high-force applications, while pneumatic presses excel at high-speed, lower-force tasks.

The decision boils down to a fundamental principle of physics. Hydraulic presses use an incompressible liquid to generate immense, controllable force. Pneumatic presses use compressible air to achieve rapid, repetitive motion.

The Core Difference: Fluid vs. Air

This single distinction in the medium they use—liquid versus gas—is the source of all their respective strengths and weaknesses.

Hydraulic Presses: The Power of Incompressible Fluid

A hydraulic press operates by pumping a fluid, typically oil, into a cylinder. Because liquids are incompressible, any force applied to the fluid is transmitted directly and multiplied, allowing the press to generate immense force, often measured in many tons.

This system provides highly accurate and repeatable pressure. As noted, the operator has complete control over the ram's movement, pressure, and position throughout the stroke, making it ideal for precision work.

Think of it like a powerful pressure washer: the water's focused, non-compressible stream delivers a powerful, concentrated impact.

Pneumatic Presses: The Speed of Compressed Air

A pneumatic press uses compressed air to drive its piston. Air, being a gas, is highly compressible. When the valve opens, the compressed air expands rapidly into the cylinder, driving the ram down with incredible speed.

However, this compressibility means the force is "spongier" and less precise. The press delivers a fast blow but doesn't offer the same level of granular control or massive force generation as a hydraulic system.

This is like an industrial leaf blower: the air moves incredibly fast to do its work, but it doesn't have the brute-force impact of a pressure washer.

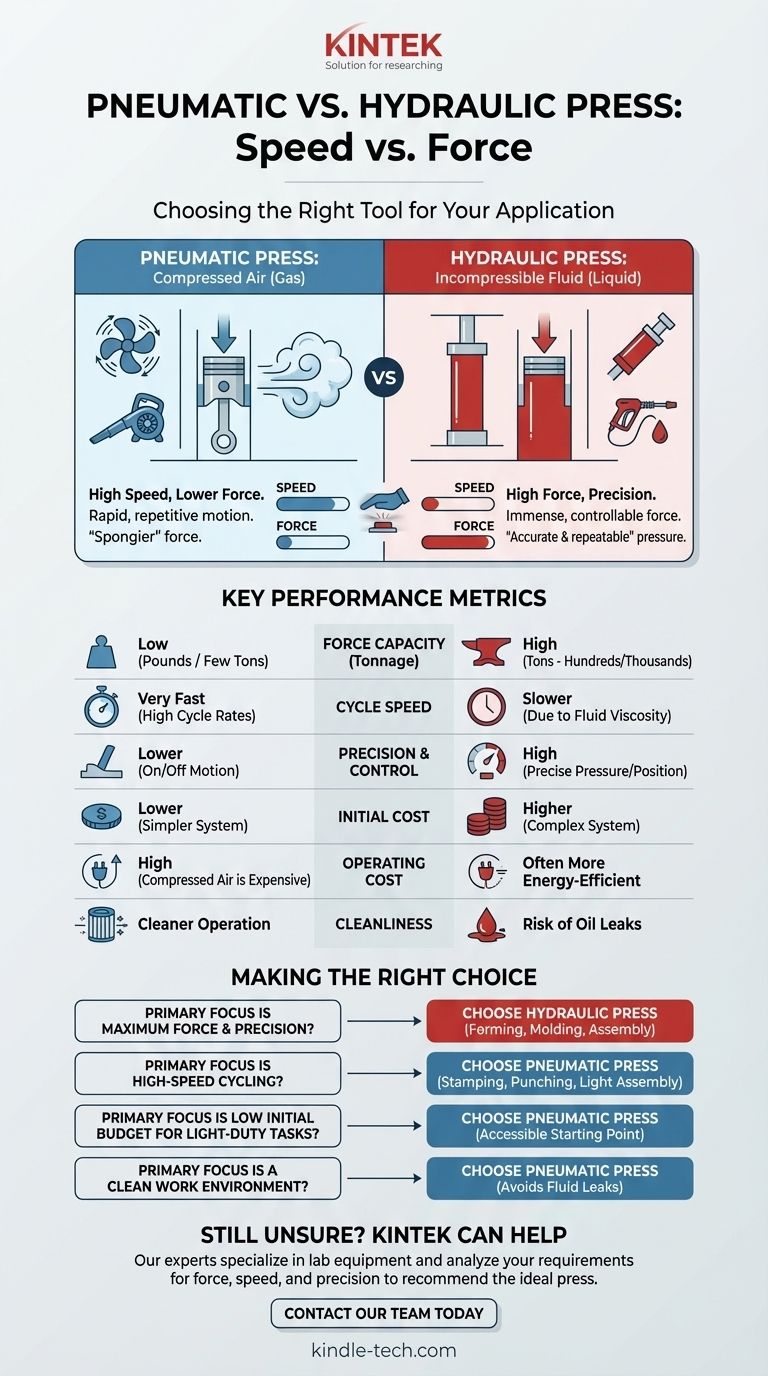

Comparing Key Performance Metrics

Let's break down how this core difference impacts their practical performance.

Force Capacity (Tonnage)

Hydraulic presses are the undisputed winners here. They can be designed to generate hundreds or even thousands of tons of force, making them essential for forging, molding, deep drawing, and crushing applications.

Pneumatic presses are limited by the pressure of the plant's air supply (typically 90-100 PSI). Their force is usually measured in pounds or just a few tons, suitable for lighter work.

Cycle Speed

Pneumatic presses are significantly faster. The rapid expansion of compressed air allows for extremely high cycle rates, perfect for applications like stamping, punching, marking, and light assembly where hundreds or thousands of cycles per hour are needed.

Hydraulic presses are inherently slower due to the need to pump a viscous fluid. While some automatic hydraulic systems are very efficient, they cannot match the raw speed of a pneumatic press.

Precision and Control

Hydraulic systems offer superior control. The incompressible fluid allows for precise adjustments to force, speed, and position at any point in the ram's stroke. This is critical for applications where a specific pressure must be applied and held.

Pneumatic presses are more of an "all or nothing" tool. They excel at moving quickly from point A to point B, but not at dwelling under a precise, controlled load.

Understanding the Trade-offs and Costs

Beyond performance, the operational realities of each system are a critical part of the decision.

Initial Investment and Complexity

Pneumatic presses are generally simpler, with fewer components. This makes them less expensive to purchase and easier to install, especially if a facility already has a compressed air system.

Hydraulic presses are more complex, requiring a hydraulic power unit (HPU), pumps, reservoirs, and more robust construction to handle the high forces. This results in a higher initial cost.

Operating Costs

This is a frequently overlooked factor. Compressed air is often one of the most expensive utilities in a manufacturing plant. The constant demand from a pneumatic press can lead to high long-term energy costs.

Hydraulic presses use electricity to run the pump, which is often only active under load. For the force they generate, they can be more energy-efficient than a pneumatic system trying to achieve a similar (though much lower) force.

Maintenance and Cleanliness

Pneumatic systems are relatively clean and low-maintenance, primarily requiring air filters and lubricators to be checked.

Hydraulic systems, while robust, present the risk of oil leaks. These leaks can create safety hazards (slips) and cleanliness issues, requiring more diligent maintenance.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational goal.

- If your primary focus is maximum force and precision: Choose a hydraulic press. It is the only choice for forming, molding, and assembly tasks requiring high tonnage and repeatable pressure control.

- If your primary focus is high-speed cycling: Choose a pneumatic press. It is ideal for rapid stamping, punching, and light assembly where speed is more important than force.

- If your primary focus is a low initial budget for light-duty tasks: Choose a pneumatic press. Its simplicity and lower cost make it an accessible starting point.

- If your primary focus is a clean work environment: A pneumatic press is generally the cleaner option, avoiding the potential for hydraulic fluid leaks.

Understanding the fundamental difference between incompressible fluid and compressible air empowers you to select the right press for your specific objective.

Summary Table:

| Feature | Hydraulic Press | Pneumatic Press |

|---|---|---|

| Primary Strength | High Force (Tonnage) | High Speed (Cycling) |

| Force Capacity | High (Tons) | Low (Pounds / Few Tons) |

| Cycle Speed | Slower | Very Fast |

| Control & Precision | High (Precise pressure/speed) | Lower (On/Off motion) |

| Initial Cost | Higher | Lower |

| Operating Cost | Often more energy-efficient | High (Compressed air is expensive) |

| Cleanliness | Risk of oil leaks | Cleaner operation |

Still Unsure Which Press is Right for Your Application?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you analyze your specific requirements for force, speed, and precision to recommend the ideal press for your workflow.

Contact our team today to discuss your project and discover how the right press can enhance your lab's efficiency and results.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy