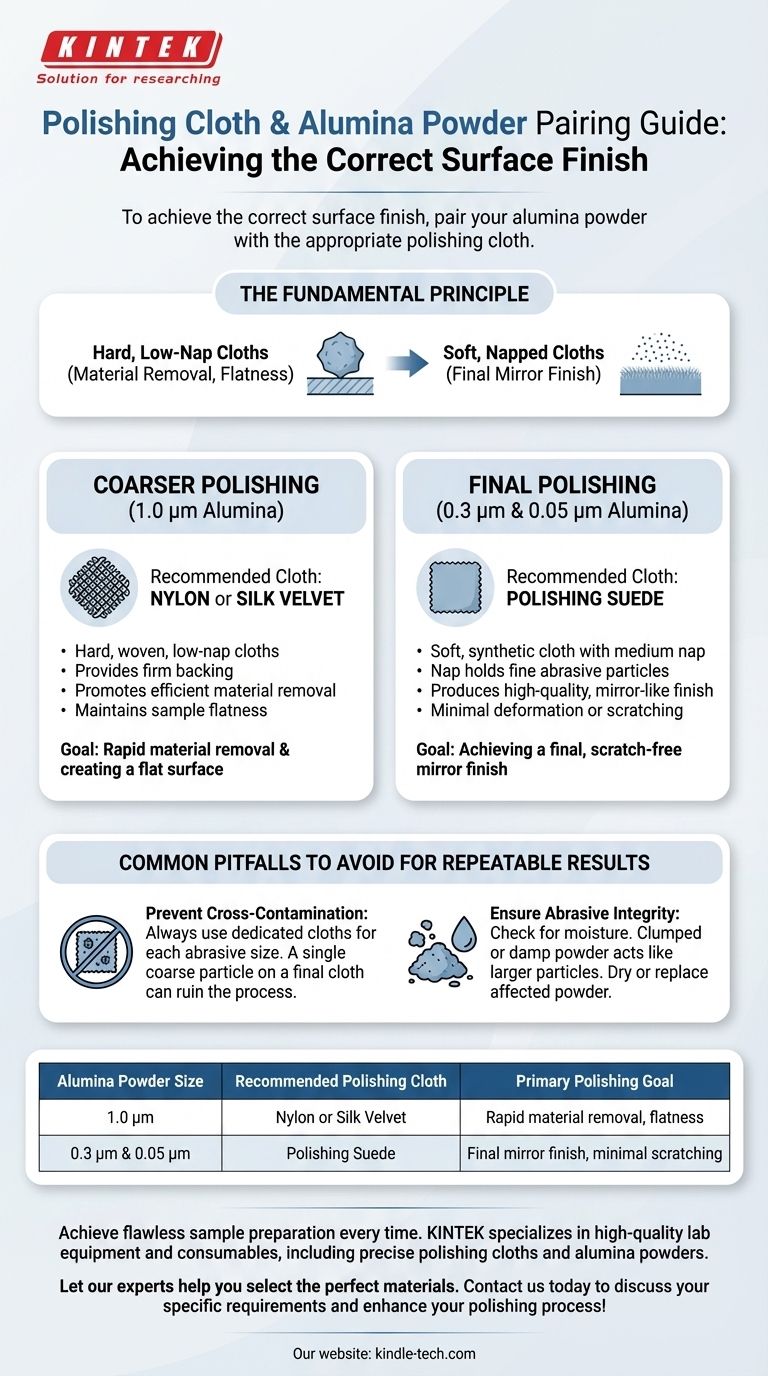

To achieve the correct surface finish, you must pair your alumina powder with the appropriate polishing cloth. For initial polishing with 1.0 µm alumina powder, use a Nylon or Silk Velvet cloth. For final, high-quality polishing with finer 0.3 µm or 0.05 µm alumina powders, you must use Polishing Suede.

The fundamental principle is that the polishing cloth and abrasive work together as a system. Hard, low-nap cloths are used with coarser abrasives for material removal, while soft, napped cloths are used with finer abrasives to achieve a final mirror finish.

The Role of the Polishing Cloth in Abrasive Action

The polishing cloth is not merely a passive carrier for the abrasive particles. It is an active component that dictates the effectiveness of the polishing step.

How Cloths Influence Polishing

A cloth's material, weave, and nap (the fuzzy surface texture) determine how the abrasive particles interact with your sample.

The right cloth ensures the abrasive is held correctly to either cut aggressively or gently burnish the surface, directly impacting the final quality and flatness of your sample.

Matching Abrasive Size to Cloth Type

The choice of cloth is directly tied to the particle size of the alumina and the goal of that specific polishing stage, whether it's rapid material removal or creating a scratch-free surface.

For Coarser Polishing (1.0 µm Alumina)

The recommended cloths for 1.0 µm alumina are Nylon or Silk Velvet.

These are typically hard, woven, low-nap cloths. Their durability and stiffness provide a firm backing for the coarser abrasive particles, promoting efficient material removal while maintaining the flatness of the sample.

For Final Polishing (0.3 µm & 0.05 µm Alumina)

For the finest alumina powders (0.3 µm and 0.05 µm), the correct choice is Polishing Suede.

This is a soft, synthetic cloth with a medium nap. The nap holds the fine abrasive particles, allowing them to produce a high-quality, mirror-like finish with minimal deformation or scratching.

Common Pitfalls to Avoid for Repeatable Results

Achieving a perfect polish is as much about avoiding errors as it is about using the correct materials. The primary goal is to prevent contamination and ensure the abrasive performs as expected.

Preventing Cross-Contamination

A single 1.0 µm particle on your final polishing suede cloth can ruin the entire process by introducing deep scratches.

Always use dedicated cloths for each abrasive size and store different alumina powder sizes separately to prevent accidental mixing.

Ensuring Abrasive Integrity

Alumina powder is chemically stable, but its physical state is critical.

Check packaging for any signs of moisture. Clumped or damp powder can act like a much larger abrasive particle, defeating the purpose of a fine polishing step. If moisture is detected, the powder must be dried or replaced.

Making the Right Choice for Your Goal

Select your cloth-and-abrasive combination based on the specific stage of your polishing process.

- If your primary focus is rapid material removal and creating a flat surface: Use 1.0 µm alumina powder with a durable Nylon or Silk Velvet cloth.

- If your primary focus is achieving a final, scratch-free mirror finish: Use 0.3 µm or 0.05 µm alumina powder with a soft Polishing Suede.

- If you are performing a multi-step process: Begin with the coarser combination and progress to the finer one, ensuring you use a separate, dedicated cloth for each step.

Ultimately, a successful polish depends on systematically matching the tool to the task at every stage.

Summary Table:

| Alumina Powder Size | Recommended Polishing Cloth | Primary Polishing Goal |

|---|---|---|

| 1.0 µm | Nylon or Silk Velvet | Rapid material removal, flatness |

| 0.3 µm & 0.05 µm | Polishing Suede | Final mirror finish, minimal scratching |

Achieve flawless sample preparation every time. The right lab supplies are critical for repeatable results. KINTEK specializes in high-quality lab equipment and consumables, including the precise polishing cloths and alumina powders your laboratory needs. Let our experts help you select the perfect materials for your application. Contact us today to discuss your specific requirements and enhance your polishing process!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Assemble Square Lab Press Mold for Laboratory Applications

- Engineering Advanced Fine Alumina (Al₂O₃) Ceramic Positioning Pin Straight Bevel for Precision Applications

People Also Ask

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights

- What are the functions of Platinum and SCE in coating corrosion testing? Enhance Data Accuracy in 3-Electrode Systems

- Why are Gas Diffusion Electrodes (GDE) critical as cathodes? Mastering Precision in Electrochemical Monitoring

- What are the features of the Iridium-Tantalum-Titanium Oxygen Evolution Electrode? Maximize Efficiency & Lifespan

- What is the role of an ultrasonic cleaner in nano-TiO2 modified electrodes? Achieve Perfect Particle Dispersion

- Why is Magnéli phase titanium suboxide (M-TiSO) used as the anode? Optimize Wastewater Treatment Efficiency

- What are the primary considerations for selecting 316L stainless steel as an electrode material? A Research Guide

- What is the function of a three-electrode system? Master Precision Film Growth for CP Sensors