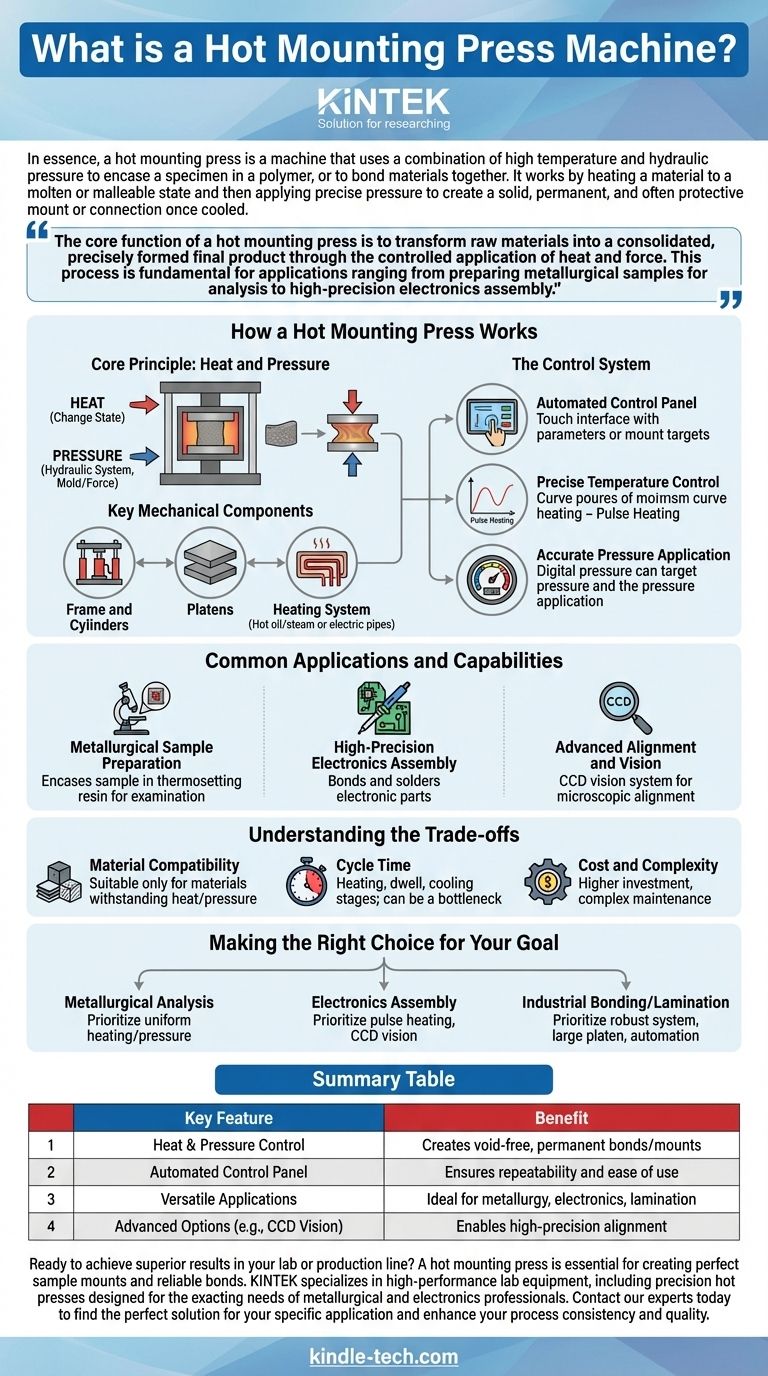

In essence, a hot mounting press is a machine that uses a combination of high temperature and hydraulic pressure to encase a specimen in a polymer, or to bond materials together. It works by heating a material, such as a thermosetting resin or solder, to a molten or malleable state and then applying precise pressure to create a solid, permanent, and often protective mount or connection once cooled.

The core function of a hot mounting press is to transform raw materials into a consolidated, precisely formed final product through the controlled application of heat and force. This process is fundamental for applications ranging from preparing metallurgical samples for analysis to high-precision electronics assembly.

How a Hot Mounting Press Works

To understand this machine, it's essential to look at its core components and the principles that govern its operation. The entire process is a practical application of thermodynamics and fluid dynamics to achieve a specific manufacturing or laboratory goal.

The Core Principle: Heat and Pressure

A hot press operates on a simple but powerful concept. It applies heat to change the state of a material, making it pliable or liquid. Simultaneously, a hydraulic system applies significant, evenly distributed pressure to mold the material or force two parts together.

This combination ensures a dense, void-free result, whether it's a perfectly encased sample for microscopic analysis or a robust electrical connection on a circuit board.

Key Mechanical Components

The machine's physical structure is designed for stability and precision under extreme force and temperature.

- Frame and Cylinders: Most units are built on a robust base housing one or more hydraulic cylinders. A rigid structure of columns or solid frames connects the base to the stationary top head, ensuring alignment and resistance to bending under pressure.

- Platens: These are the thick, flat steel plates that heat the material. They are typically machined to be perfectly flat and are often chromium-plated to prevent materials from sticking and to resist corrosion.

- Heating System: Channels are drilled through the platens to circulate a heating medium like hot oil or steam. Alternatively, integrated electric heating pipes provide rapid and direct heat conduction.

The Control System

Modern hot presses are defined by their advanced control systems, which allow for high levels of precision and repeatability.

- Automated Control Panel: An easy-to-use touch interface allows a single operator to manage the entire process, setting parameters like temperature, pressure, and time.

- Precise Temperature Control: Sophisticated systems use pulse heating technology and multi-stage temperature controls to follow a specific heating and cooling profile. Real-time temperature curves are often displayed to monitor the process.

- Accurate Pressure Application: A digital pressure gauge allows the operator to preset the exact pressure required. The hydraulic system and adjustable cylinders ensure this pressure is applied evenly and consistently.

Common Applications and Capabilities

The versatility of a hot press makes it valuable across several technical fields. Its capabilities are defined by its precision in controlling the core variables of heat, pressure, and time.

Metallurgical Sample Preparation

This is the classic use for a "hot mounting press." A small material sample (e.g., a piece of metal) is placed in a cylinder with a thermosetting resin powder (like Bakelite). The press heats the resin until it flows and applies pressure to consolidate it around the sample, creating a hard, standardized puck that is easy to handle, polish, and examine under a microscope.

High-Precision Electronics Assembly

In electronics, hot presses are used for bonding and soldering. The machine heats two parts pre-coated with flux and solder to a temperature sufficient to melt the solder. The pressure head then ensures a strong, permanent electrical and mechanical connection is formed as it cools.

Advanced Alignment and Vision

For highly sensitive applications like flexible circuit board assembly, some machines are equipped with a CCD vision system. This allows for microscopic alignment of components before the pressing cycle begins, ensuring perfect placement and connection.

Understanding the Trade-offs

While powerful, a hot mounting press is not the solution for every scenario. Understanding its limitations is key to using it effectively.

Material Compatibility

The primary limitation is the material itself. The process is only suitable for specimens and components that can withstand the required temperatures and pressures without being damaged, deformed, or having their intrinsic properties altered.

Cycle Time

The process is not instantaneous. It involves a heating stage, a pressure application (or "dwell") stage, and a cooling stage. This complete cycle can take several minutes, which may be a bottleneck in high-volume production compared to other joining methods.

Cost and Complexity

These are sophisticated machines that integrate hydraulic, heating, and advanced electronic control systems. This results in a higher initial investment and more complex maintenance requirements compared to simpler benchtop tools or manual methods.

Making the Right Choice for Your Goal

Selecting or specifying a hot press depends entirely on the intended application.

- If your primary focus is high-quality metallurgical analysis: Prioritize a machine with extremely uniform heating and pressure to create void-free sample mounts for accurate microscopic examination.

- If your primary focus is precision electronics assembly: Look for features like pulse heating for rapid temperature control, a CCD vision system for alignment, and the ability to save complex, multi-stage process programs.

- If your primary focus is industrial bonding or lamination: Emphasize a robust hydraulic system for stability, a large platen size, and automated controls that allow a single operator to manage the machine efficiently.

Ultimately, a hot mounting press is a tool that provides unparalleled control over heat and force, enabling you to create highly consistent and reliable material bonds and sample preparations.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Heat & Pressure Control | Creates void-free, dense, and permanent bonds or mounts. |

| Automated Control Panel | Ensures process repeatability and ease of use for operators. |

| Versatile Applications | Ideal for metallurgy, electronics assembly, and material lamination. |

| Advanced Options (e.g., CCD Vision) | Enables high-precision alignment for sensitive components. |

Ready to achieve superior results in your lab or production line? A hot mounting press is essential for creating perfect sample mounts and reliable bonds. KINTEK specializes in high-performance lab equipment, including precision hot presses designed for the exacting needs of metallurgical and electronics professionals. Contact our experts today to find the perfect solution for your specific application and enhance your process consistency and quality.

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the purpose of alumina polishing powder in GCE pretreatment? Master Surface Prep for Electrochemistry

- What method is widely used for mounting of specimens? Achieve Perfect Histological Slides with Proven Techniques

- What is the purpose of using epoxy resin and laboratory mounting equipment? Precision in U71Mn Weld Area Analysis

- What are the properties and handling precautions for alumina powder as a polishing material? Achieve a Flawless Finish with Precision

- How do laboratory mounting systems or hydraulic presses assist in oxide layer prep? Ensure Perfect Sample Integrity

- What is the function and maintenance of a polishing glass base? Ensure Perfect Sample Preparation Every Time

- What are the properties and care instructions for metallographic polishing silk velvet cloth? Achieve a Perfect Mirror Finish

- How is a laboratory hydraulic press used in metal mounting? Achieve Precision in Microstructure Analysis