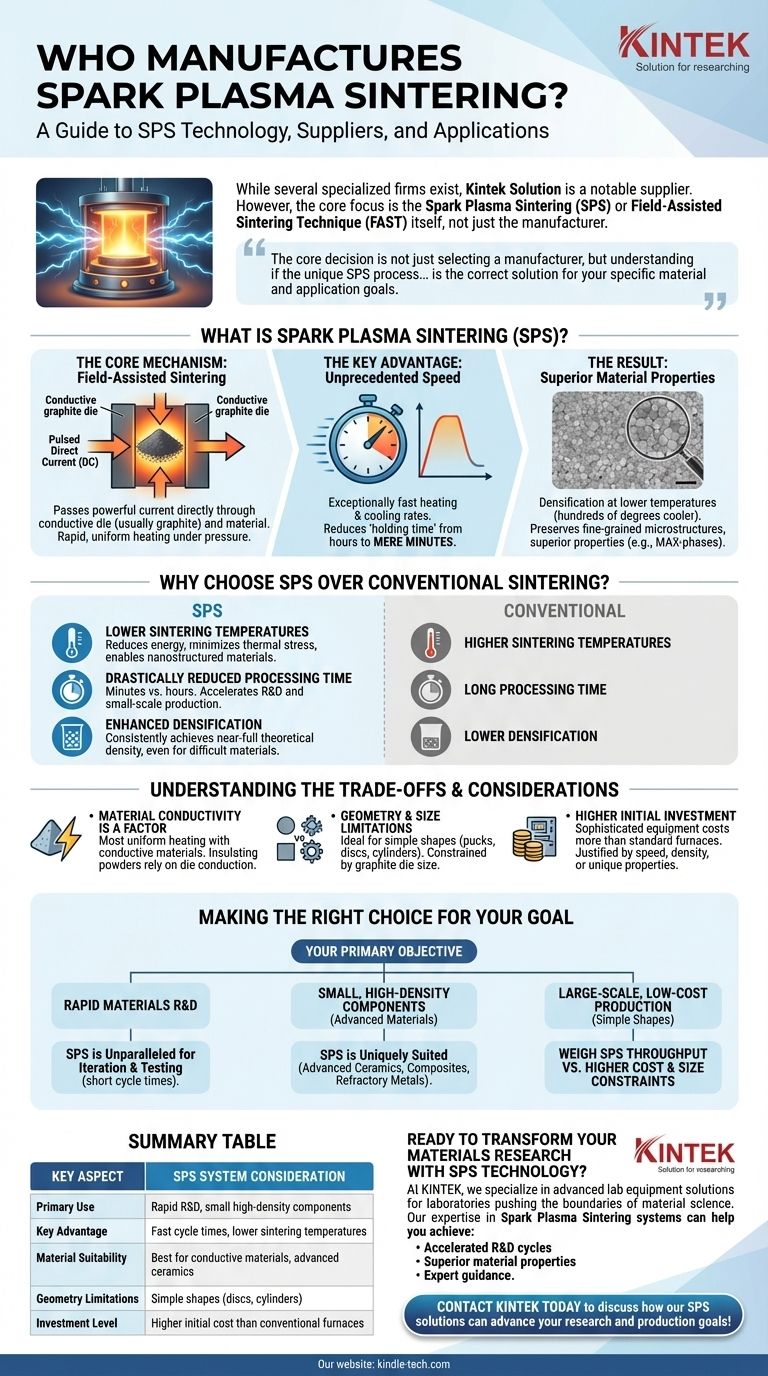

While several specialized firms manufacture Spark Plasma Sintering (SPS) systems, a notable example mentioned in technical literature is Kintek Solution. Beyond a single name, it's crucial to understand that this is a niche field with a number of global suppliers, each offering systems tailored to specific research and production needs. The technology itself, also known as Field-Assisted Sintering Technique (FAST), is more important than any single manufacturer.

The core decision is not just selecting a manufacturer, but understanding if the unique SPS process—which uses direct electrical current for extremely rapid, low-temperature densification—is the correct solution for your specific material and application goals.

What is Spark Plasma Sintering (SPS)?

SPS is a revolutionary sintering process that fundamentally changes how powdered materials are consolidated into a dense, solid mass. It moves beyond the slow, indirect heating of a conventional furnace.

The Core Mechanism: Field-Assisted Sintering

An SPS system passes a powerful electrical current—typically a pulsed Direct Current (DC)—directly through a conductive die, which is usually made of graphite.

If the material powder inside the die has some electrical conductivity, the current also passes through the material itself.

This creates rapid, uniform heating from both the outside (the die) and the inside (the powder), all while under applied pressure.

The Key Advantage: Unprecedented Speed

The direct, simultaneous heating allows for exceptionally fast heating and cooling rates.

This reduces the required "holding time" at peak temperature from hours, which is common in conventional methods, to mere minutes.

The Result: Superior Material Properties

This rapid cycle allows for densification at significantly lower temperatures, often hundreds of degrees cooler than traditional sintering.

This preserves fine-grained microstructures and prevents unwanted grain growth, leading to materials with superior mechanical properties. It has proven especially effective for advanced materials like MAX-phases.

Why Choose SPS Over Conventional Sintering?

The unique mechanism of SPS offers distinct, measurable advantages over traditional furnace-based methods like hot pressing or pressureless sintering.

Lower Sintering Temperatures

By consolidating materials at lower temperatures, SPS reduces energy consumption and minimizes thermal stress on the final part. It also allows for the creation of nanostructured materials that would otherwise be destroyed by high heat.

Drastically Reduced Processing Time

The ability to complete a full sintering cycle in minutes instead of hours dramatically accelerates research, development, and small-scale production, enabling more rapid innovation.

Enhanced Densification

SPS consistently achieves near-full theoretical density, even with materials that are notoriously difficult to sinter. This is critical for high-performance applications where porosity is a point of failure.

Understanding the Trade-offs and Considerations

While powerful, SPS technology is not a universal solution. An objective assessment requires understanding its limitations.

Material Conductivity is a Factor

The most uniform heating occurs when the material itself is conductive. For electrically insulating powders, heating relies solely on thermal conduction from the die, which can be less efficient and uniform.

Geometry and Size Limitations

The process is constrained by the size and shape of the graphite dies. This makes SPS ideal for producing simple geometries like pucks, discs, and cylinders but less suitable for highly complex, large-scale parts.

Higher Initial Investment

SPS systems are sophisticated pieces of equipment that represent a significantly higher capital investment than a standard high-temperature furnace. The cost must be justified by the need for speed, density, or unique material properties.

Making the Right Choice for Your Goal

To determine if an SPS system is the right investment, align the technology's strengths with your primary objective.

- If your primary focus is rapid materials research and development: SPS is an unparalleled tool for quickly iterating and testing new material compositions due to its incredibly short cycle times.

- If your primary focus is producing small, high-density components from difficult-to-sinter materials: The unique densification mechanism of SPS makes it uniquely suited for advanced ceramics, composites, and refractory metals.

- If your primary focus is large-scale, low-cost production of simple shapes: You must carefully weigh the high throughput of SPS against the higher initial cost and size constraints compared to conventional methods.

Ultimately, understanding the fundamental principles of the SPS process is the critical first step in leveraging its transformative potential for your project.

Summary Table:

| Key Aspect | SPS System Consideration |

|---|---|

| Primary Use | Rapid R&D, small high-density components |

| Key Advantage | Fast cycle times, lower sintering temperatures |

| Material Suitability | Best for conductive materials, advanced ceramics |

| Geometry Limitations | Simple shapes (discs, cylinders) |

| Investment Level | Higher initial cost than conventional furnaces |

Ready to Transform Your Materials Research with SPS Technology?

At KINTEK, we specialize in advanced lab equipment solutions for laboratories pushing the boundaries of material science. Our expertise in Spark Plasma Sintering systems can help you achieve:

• Accelerated R&D cycles with rapid sintering times • Superior material properties through low-temperature densification • Expert guidance on selecting the right SPS solution for your specific needs

Whether you're working with advanced ceramics, composites, or refractory metals, our team can help you leverage SPS technology to achieve breakthrough results.

Contact KINTEK today to discuss how our SPS solutions can advance your research and production goals!

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- What are the key differences between the cold press and sinter process and the hot-pressing process for oxides?

- What are the advantages of an SPS? Achieve Superior Materials with Unprecedented Speed and Control

- What effect does pressure have on sintering? Accelerate Densification and Boost Material Performance

- What pressurization methods are employed in a vacuum hot pressing furnace? Choose the Right Method for Your Materials

- What role does a vacuum hot pressing furnace play in Ti2AlNb/TA15 fabrication? Achieve Seamless Diffusion Bonding

- What role does a Hot Isostatic Pressing (HIP) furnace play in processing ATO? Achieve Maximum Density & Conductivity

- What can I make with a vacuum press? Unlock Perfect Laminating and Curved Forms

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication