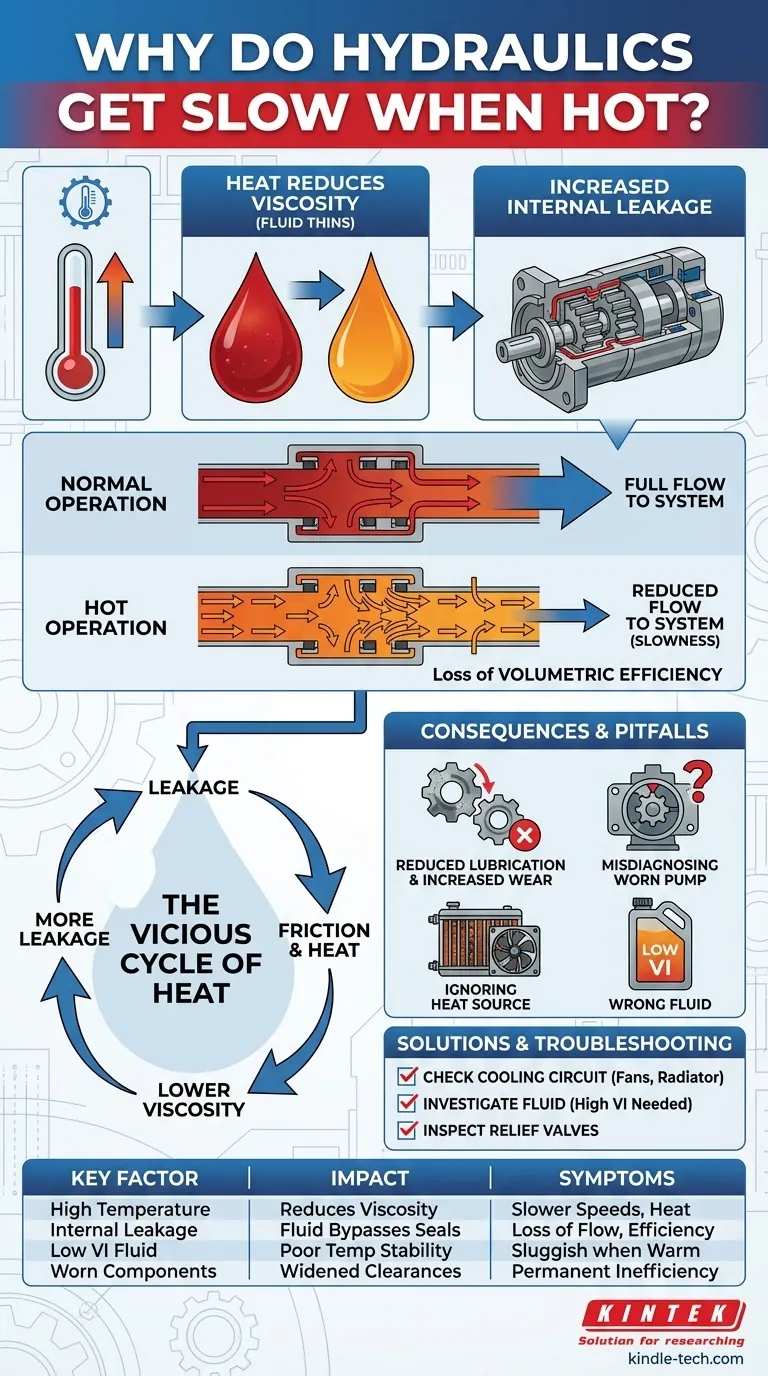

When a hydraulic system gets hot, it slows down because the hydraulic fluid becomes thinner and less resistant to flow. This property, known as viscosity, is critical for system performance. As the fluid's viscosity drops, it more easily bypasses the tight internal seals in pumps and motors, a phenomenon called internal leakage. This means less fluid is available to do useful work, directly resulting in slower actuator speeds.

The core issue is a loss of volumetric efficiency. Heat reduces the oil's viscosity, allowing more of it to slip past the internal clearances of a pump instead of being delivered to the circuit. This internal leakage means less flow reaches the cylinders and motors, causing them to move slower for the same pump input speed.

The Critical Role of Viscosity

To understand why heat causes this slowdown, you must first grasp the concept of viscosity and its function within a hydraulic system.

What is Viscosity?

Viscosity is a fluid's resistance to flow and shear. Think of the difference between pouring water (low viscosity) and honey (high viscosity).

Hydraulic systems are designed to operate within a specific viscosity range. The fluid must be thin enough to flow easily through the system but thick enough to seal clearances and provide adequate lubrication.

Why Ideal Viscosity Matters

When the fluid is within its ideal operating range, it creates a strong, lubricating film between moving parts and effectively seals the microscopic gaps inside components like pumps, motors, and valves.

This sealing function is what ensures the pump moves a predictable volume of oil with each revolution.

The Viscosity Index (VI)

Not all hydraulic fluids react to heat the same way. The Viscosity Index (VI) is a measure of how much a fluid's viscosity changes with temperature.

A fluid with a high VI maintains a more stable viscosity across a wide temperature range, which is highly desirable. A low VI fluid will thin out dramatically when hot, exacerbating performance issues.

How Heat Degrades Performance

When a system overheats, the drop in viscosity creates a cascade of negative effects, with internal leakage being the most significant cause of slowness.

Internal Leakage in Pumps and Motors

Hydraulic pumps and motors are not perfectly sealed. They rely on extremely tight clearances—thousandths of an inch—between gears, vanes, or pistons and their housings.

When the oil is at the correct viscosity, only a small, acceptable amount leaks from the high-pressure side back to the low-pressure side. When the oil gets hot and thin, this internal leakage increases significantly.

The pump is still spinning at the same speed, but a larger portion of the fluid it's trying to move is slipping internally instead of being forced out into the system. This directly reduces the flow rate (gallons per minute) delivered to the actuators.

The Vicious Cycle of Heat

This internal leakage creates a vicious cycle. As high-pressure fluid squeezes through small internal clearances, the friction generates even more heat.

This additional heat further lowers the fluid's viscosity, which in turn increases the rate of internal leakage, generating more heat still. This feedback loop can cause system temperatures to run away if not controlled.

Reduced Lubrication and Increased Wear

A secondary effect of low viscosity is inadequate lubrication. The oil film separating moving metal parts becomes weaker.

This leads to increased friction and wear on pumps, motors, and valves. This wear widens the internal clearances, permanently increasing internal leakage and making the system even more susceptible to heat-related performance loss in the future.

Understanding the Common Pitfalls

A slow, hot hydraulic system is a symptom, not the root cause. Focusing only on the slowness can lead to incorrect and expensive decisions.

Misdiagnosing a Worn-Out Pump

A common mistake is to assume a slow hydraulic pump is simply "worn out" and needs replacement. While a worn pump will certainly be slow, an overheated system with a perfectly good pump will exhibit the exact same symptoms.

If a system slows down only after it reaches a high operating temperature, the primary problem is almost certainly heat, not component failure.

Ignoring the Source of the Heat

The real issue is often found in the system's inability to dissipate heat. The slowness is just the most obvious consequence.

Root causes for overheating often include a clogged heat exchanger (radiator), a failing cooler fan, low fluid level in the reservoir, or a relief valve that is stuck or improperly set, causing it to constantly bypass oil at high pressure.

Using the Wrong Hydraulic Fluid

Using a fluid with a low Viscosity Index (VI) or the wrong viscosity grade for the ambient climate can cripple a system. The fluid may be too thin to begin with or may thin out excessively as soon as the system reaches operating temperature.

How to Apply This to Your System

To effectively troubleshoot, you must shift your focus from the symptom (slowness) to the cause (excess heat or incorrect fluid properties).

- If your system slows down only after extended, heavy use: Your primary focus should be the cooling circuit. Check for clogged cooler fins, ensure the fan is operational, and verify the reservoir fluid level is correct.

- If your system feels sluggish even when only moderately warm: Investigate the hydraulic fluid itself. You may be using a fluid with too low a viscosity or a poor Viscosity Index (VI) for your application.

- If you notice a sudden increase in heat and noise: Immediately inspect your pressure relief valves. A valve that is constantly bypassing is a massive generator of heat and a common cause of system meltdown.

- If the system is old and has always been slow when hot: The cumulative effect of years of wear may have opened up internal clearances in the pump and motors, making them highly inefficient at higher temperatures.

By understanding that heat directly attacks a fluid's viscosity, you can move from treating symptoms to solving the root cause of hydraulic inefficiency.

Summary Table:

| Key Factor | Impact on System | Common Symptoms |

|---|---|---|

| High Temperature | Reduces fluid viscosity (thins the oil) | Slower actuator speeds, increased heat |

| Internal Leakage | Fluid bypasses pump/motor seals | Loss of flow, reduced volumetric efficiency |

| Low Viscosity Index (VI) | Poor temperature stability | Sluggish performance even at moderate heat |

| Worn Components | Widened internal clearances | Permanent inefficiency, heat sensitivity |

Is your hydraulic system losing efficiency due to heat? KINTEK specializes in high-performance hydraulic fluids and lab equipment designed to maintain optimal viscosity and prevent internal leakage. Our products help you achieve precise temperature control and extend the life of your components. Don't let heat slow you down—contact our experts today for a solution tailored to your laboratory's hydraulic needs!

Visual Guide

Related Products

- Manual Lab Heat Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What are the potential hazards in a hydraulic press? Understanding the Risks of Crushing, Injection, and Failure

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What are the parts of a manual hydraulic press? A Guide to Its Core Components and Operation

- What is the efficiency of a hydraulic press? Harness Unmatched Force Multiplication for Your Lab