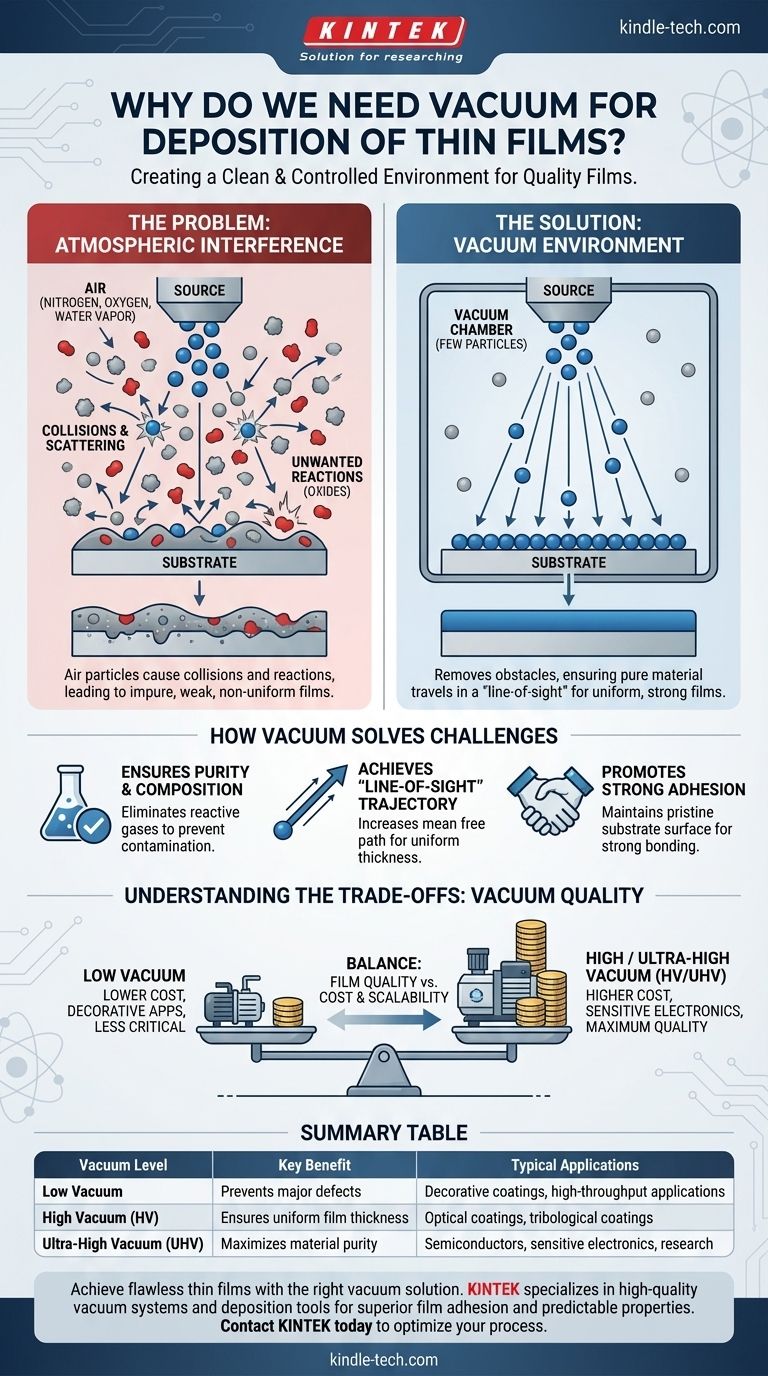

In short, a vacuum is required for thin film deposition to create a clean and controlled environment. Without it, the material being deposited would collide with and react to the billions of particles in the air, such as oxygen and water vapor. This interference would prevent the formation of a pure, uniform, and well-adhered film on the substrate surface.

The fundamental reason for using a vacuum is to remove obstacles. Air particles scatter the deposition material and chemically contaminate it, leading to weak, impure films with unpredictable properties. A vacuum ensures the material travels unimpeded from its source to the substrate, which is the basis for creating any high-quality thin film.

The Core Problem: Interference from the Atmosphere

To understand the need for a vacuum, you must first recognize that ambient air is not empty. It is a dense environment filled with reactive gases that are hostile to the precision required for thin film deposition.

The Challenge of Particle Collisions

At standard atmospheric pressure, a cubic centimeter of air contains trillions of gas molecules, primarily nitrogen, oxygen, and water vapor.

These atmospheric particles get in the way of the material being deposited. The deposition material, which is traveling from a source to the substrate, will inevitably collide with these gas molecules.

These collisions scatter the deposition material, causing it to deviate from its intended path. This scattering results in a non-uniform film thickness and poor coverage over the substrate's surface features.

The Threat of Unwanted Chemical Reactions

Beyond simple physical collisions, the gases in the air are chemically reactive. Oxygen and water vapor are particularly aggressive contaminants.

When the hot, energetic deposition material meets these reactive gases, unwanted chemical reactions occur. For example, depositing a pure metal in the open air will almost certainly result in the formation of a metal oxide, not a pure metal film.

This contamination fundamentally alters the film's properties—changing its electrical conductivity, optical characteristics, and structural integrity. The final product is impure and fails to meet the desired specifications.

How Vacuum Solves the Key Deposition Challenges

By removing the vast majority of air molecules from a sealed chamber, a vacuum directly addresses the problems of collision and contamination. This control is what enables modern electronics, optics, and material science.

Ensuring Purity and Composition Control

A vacuum environment is, by definition, an environment with very few particles. By pumping out the reactive gases, you eliminate the source of chemical contamination.

This ensures that the film being deposited is composed of only the intended source material. This level of purity is non-negotiable for applications like semiconductors, where even minor impurities can render a device useless.

Achieving a "Line-of-Sight" Trajectory

In a high vacuum, the average distance a particle can travel before hitting another one—known as the mean free path—increases from nanometers to many meters.

This means the deposition material can travel in a straight, uninterrupted line from the source to the substrate. This "line-of-sight" travel is critical for achieving uniform film thickness and predictable deposition rates across the entire substrate.

Promoting Strong Adhesion

For a film to stick properly, its first atomic layer must form a strong bond with the substrate surface. If a layer of contaminants (like oxides or adsorbed water) exists on the substrate, the film will adhere to that weak layer instead.

A vacuum not only cleans the path for the deposition material but also helps maintain a pristine substrate surface before and during deposition, preventing this weak boundary layer from forming and ensuring strong film adhesion.

Understanding the Trade-offs: The "Quality" of the Vacuum

Not all processes require the same level of vacuum. The decision involves a critical balance between the desired film quality, the process cost, and the sensitivity of the materials involved.

Low vs. High Vacuum

The "quality" of a vacuum is measured by its pressure. A low vacuum still has a significant number of gas molecules, while a high vacuum (HV) or ultra-high vacuum (UHV) has progressively fewer.

Simple processes like decorative metallic coatings may only require a low or medium vacuum. In contrast, manufacturing sensitive semiconductor or optical components requires HV or UHV to achieve the necessary purity and structural perfection.

The Cost of Cleanliness

Achieving a higher vacuum is more difficult, time-consuming, and expensive. It requires more sophisticated pumps and longer "pump-down" times to remove more and more molecules from the chamber.

This creates a direct trade-off between film quality and manufacturing cost/scalability. The goal is always to use a vacuum level that is sufficient for the application's needs without incurring unnecessary expense or production delays.

Making the Right Choice for Your Goal

The required vacuum level is dictated by the desired properties of the final film. Your application's sensitivity to contamination and structural defects will determine the necessary investment in your vacuum system.

- If your primary focus is material purity for electronics or research: You must use a high or ultra-high vacuum (UHV) to minimize chemical reactions with residual gases like oxygen and water.

- If your primary focus is uniform optical or tribological coatings: A high vacuum is typically necessary to ensure a long mean free path, preventing particle scattering that would degrade film uniformity and performance.

- If your primary focus is high-throughput decorative applications: A lower-quality vacuum may be acceptable, providing a cost-effective balance that prevents major defects while prioritizing speed.

Ultimately, controlling the deposition environment through vacuum is the foundational step in engineering the precise properties of any high-performance thin film.

Summary Table:

| Vacuum Level | Key Benefit | Typical Applications |

|---|---|---|

| Low Vacuum | Prevents major defects | Decorative coatings, high-throughput applications |

| High Vacuum (HV) | Ensures uniform film thickness | Optical coatings, tribological coatings |

| Ultra-High Vacuum (UHV) | Maximizes material purity | Semiconductors, sensitive electronics, research |

Achieve flawless thin films with the right vacuum solution.

Whether you are developing sensitive electronics, high-performance optical coatings, or high-throughput decorative applications, the purity and uniformity of your thin film are critical to your success. KINTEK specializes in providing high-quality lab equipment, including vacuum systems and deposition tools, tailored to meet the precise needs of your laboratory.

Our expertise ensures you can control your deposition environment effectively, leading to superior film adhesion, predictable properties, and reliable performance. Let us help you select the perfect vacuum system to optimize your process and enhance your results.

Contact KINTEK today to discuss your thin film deposition requirements and discover how our solutions can advance your research and production.

Visual Guide

Related Products

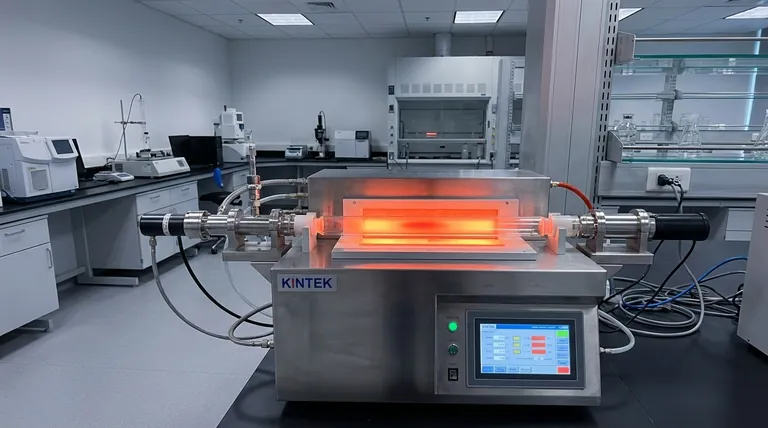

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance