At its core, vacuum heat treatment is used to gain absolute control over a material's transformation. By removing air and its reactive elements from a furnace chamber, you create a chemically pure environment. This prevents unwanted reactions like oxidation at high temperatures, ensuring the final product has a clean surface and precisely engineered internal properties.

The fundamental purpose of a vacuum in heat treatment is not merely to remove air, but to eliminate unpredictable variables. It transforms the process from an art into a science, guaranteeing that a metal part achieves its desired strength, hardness, and finish with perfect consistency.

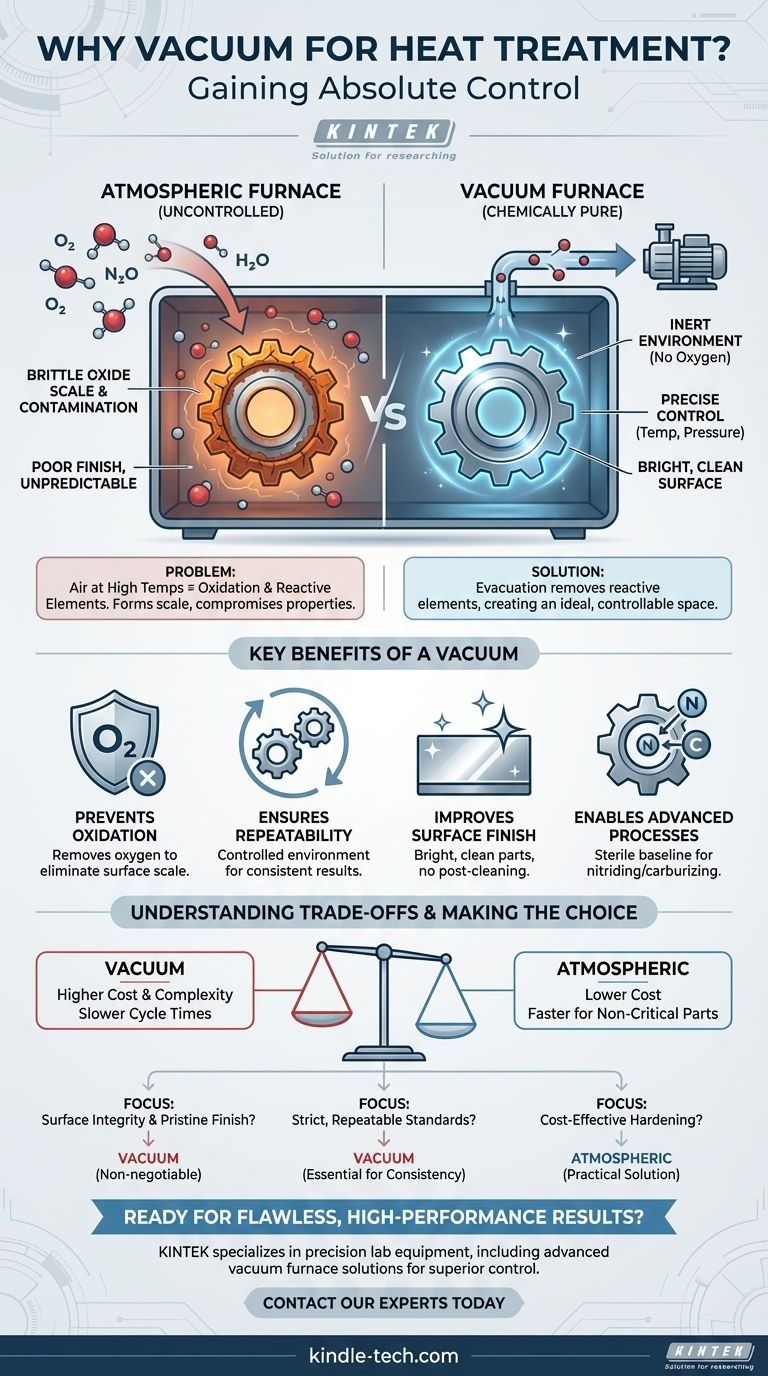

The Problem With Air at High Temperatures

To understand the need for a vacuum, we must first recognize the problem it solves. Treating metals at high temperatures in a normal atmosphere introduces significant and often detrimental chemical reactions.

The Role of Oxygen

The air around us is approximately 21% oxygen, which is highly reactive at elevated temperatures. When a metal part is heated in the presence of oxygen, it leads to oxidation.

This reaction forms a brittle layer of oxide scale on the part's surface. This scale must be removed in a secondary step, can compromise dimensional tolerances, and results in a poor surface finish.

The Impact of Other Gases

Beyond oxygen, other atmospheric components like water vapor can cause undesirable effects. These elements can contaminate the metal's surface or react with its alloys, altering its chemical composition and compromising its final mechanical properties.

How a Vacuum Creates a Superior Process

By evacuating the furnace chamber, we remove the reactive elements that cause these problems. This establishes an ideal environment for precise metallurgical control.

Creating a Chemically Inert Environment

A vacuum creates an unreactive, or inert, space. With virtually no oxygen or other atmospheric gases present, the metal can be heated to extreme temperatures without the risk of oxidation or surface contamination.

The result is a part that emerges from the furnace with a bright, clean surface finish, often eliminating the need for post-treatment cleaning or machining.

Achieving Absolute Process Repeatability

An open atmosphere is an uncontrolled variable. A vacuum is a highly controlled one. In a vacuum furnace, parameters like temperature and pressure are managed with extreme precision.

This level of control ensures that every treatment cycle is identical. For industries with stringent quality standards, this guarantees repeatable results, ensuring every component meets its specified performance criteria without deviation.

Enabling Advanced Treatments

The vacuum environment serves as a perfect, sterile baseline. Once the chamber is evacuated, specific gases like nitrogen or argon can be intentionally introduced in precise amounts.

This allows for specialized processes where the goal is to intentionally modify the surface of a material, such as nitriding or carburizing, without interference from unwanted atmospheric elements.

Understanding the Trade-offs

While vacuum heat treatment offers superior results, it is a more advanced and demanding process. Objectivity requires acknowledging its limitations.

Cost and Complexity

Vacuum furnaces are significantly more expensive to build and operate than standard atmospheric furnaces. They require complex pumping systems, robust seals, and sophisticated control systems.

Slower Cycle Times

The process of evacuating the chamber to the required low pressure—known as pump-down—adds time to each treatment cycle. For high-volume, low-margin parts, this can impact throughput.

When It Might Be Overkill

For many applications where surface finish is not critical or where a slight oxide layer is acceptable, a simpler and more cost-effective atmospheric furnace is perfectly adequate. The choice depends entirely on the part's final requirements.

Making the Right Choice for Your Application

Selecting the right heat treatment process is a matter of aligning the method with your engineering goals.

- If your primary focus is surface integrity and a pristine finish: Vacuum treatment is non-negotiable, as it is the only way to completely prevent oxidation.

- If your primary focus is meeting strict, repeatable metallurgical standards: The unparalleled control of a vacuum furnace is essential for guaranteeing consistent results.

- If your primary focus is cost-effective hardening for non-critical parts: A conventional atmospheric furnace is often the more practical and economical solution.

Ultimately, employing a vacuum elevates heat treatment from a bulk process to a precision engineering tool for creating flawless, high-performance components.

Summary Table:

| Key Benefit | Description |

|---|---|

| Prevents Oxidation | Removes oxygen to eliminate surface scale and contamination. |

| Ensures Repeatability | Creates a controlled environment for consistent, predictable results. |

| Improves Surface Finish | Produces bright, clean parts without need for post-treatment cleaning. |

| Enables Advanced Processes | Provides a sterile baseline for treatments like nitriding and carburizing. |

Ready to achieve flawless, high-performance results with your metal components?

At KINTEK, we specialize in precision lab equipment, including advanced vacuum furnace solutions. Our expertise ensures you gain the absolute control needed for superior surface integrity and repeatable metallurgical standards.

Let us help you select the right heat treatment process for your specific application. Contact our experts today to discuss your laboratory's needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What role does a vacuum drying oven play in PEO-RPPO composite membrane fabrication? Optimize Solid Electrolyte Purity

- What are the 4 heat treatments of steel? Master Hardness, Toughness & More

- What is the difference between calcination and sintering furnace? A Guide to Thermal Processing Goals

- What is the temperature range of arc heating? Unlock Extreme Heat for Industrial Applications

- Why are high-temperature testing furnaces over 2000°C needed for SiC cladding? Validate Gen IV Nuclear Safety

- What is the temperature of the arc melting furnace? Achieve 3000°C for Refractory Metals

- Why is it necessary to process samples in a vacuum drying oven before sputtering? Ensure Coating Purity and Adhesion

- Can you run your furnace with a generator? Power Your Heat Safely and Correctly