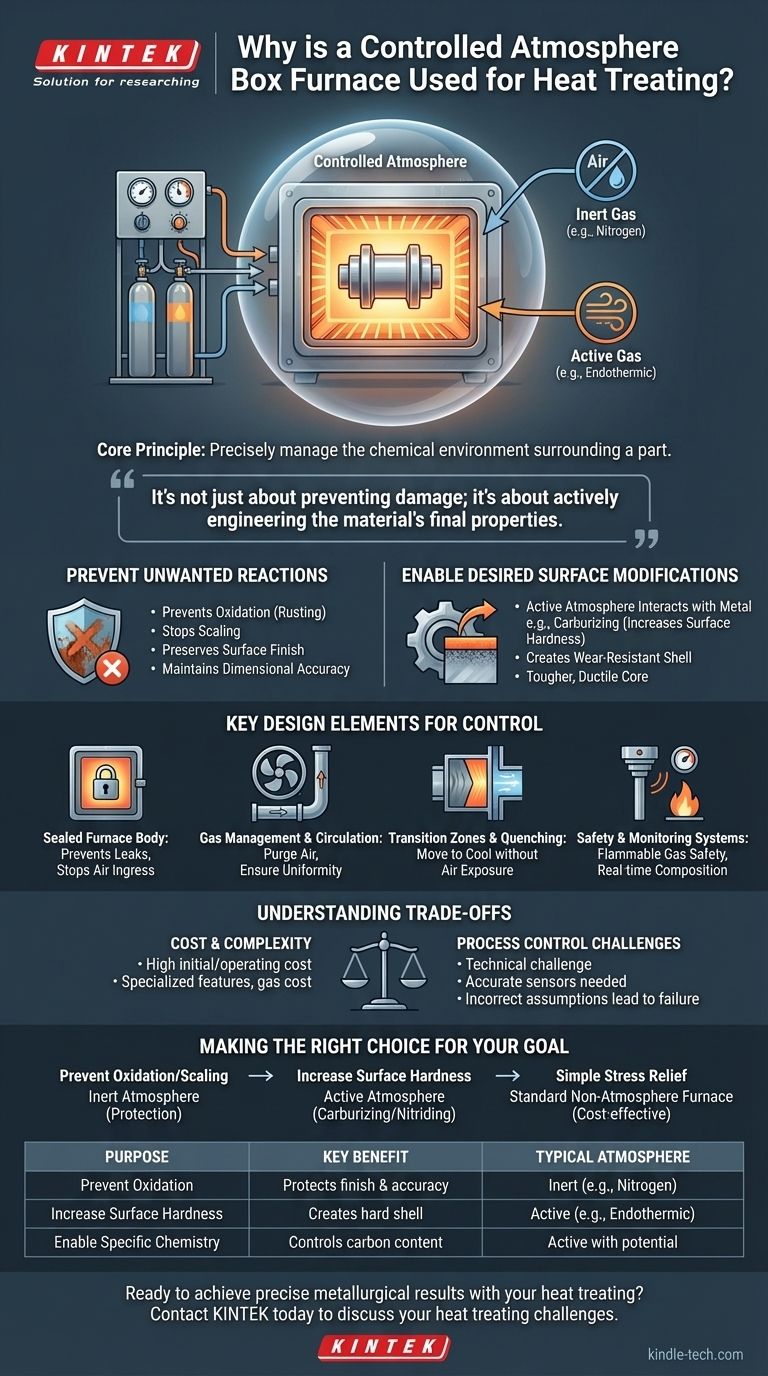

At its core, a controlled atmosphere box furnace is used for heat treating to precisely manage the chemical environment surrounding a part. This control prevents unwanted reactions, like oxidation (rusting) and scaling, while also enabling specific, desirable chemical changes to the material's surface, such as increasing its hardness.

The crucial takeaway is that controlling the furnace atmosphere transforms heat treatment from a simple heating and cooling process into a sophisticated metallurgical tool. It's not just about preventing damage; it's about actively engineering the material's final properties to meet demanding specifications.

The Fundamental Role of the Atmosphere

The gas inside the furnace is not just filler space; it is a critical process variable that directly interacts with the metal being treated, especially at high temperatures. The choice of atmosphere determines the success of the entire operation.

Preventing Unwanted Reactions

When heated in the presence of oxygen, most metals will rapidly oxidize. This creates a layer of scale on the surface that can ruin the part's finish and dimensional accuracy.

A controlled atmosphere furnace replaces the air with a specific gas mixture that prevents these destructive reactions from occurring, preserving the integrity of the workpiece.

Enabling Desired Surface Modifications

Beyond simple protection, an active atmosphere is designed to intentionally react with the surface of the metal.

Processes like carburizing introduce carbon into the surface of steel, creating a part with a very hard, wear-resistant outer shell and a tougher, more ductile core. This is only possible in an atmosphere with a precisely controlled carbon potential.

Key Design Elements for Atmospheric Control

A furnace cannot maintain a specific atmosphere without specialized design features. These components work together to create a sealed, manageable environment.

The Sealed Furnace Body

The foundation of any atmosphere furnace is an exceptionally well-sealed chamber. This integrity is vital to prevent the controlled atmosphere from leaking out and, more importantly, to stop outside air (oxygen) from leaking in.

Gas Management and Circulation

A system is required to introduce the desired gases, purge the initial air, and maintain the correct composition throughout the heating cycle. A sealed fan circulates the gas to ensure uniform temperature and chemical exposure on all surfaces of the workpiece.

Transition Zones and Quenching

A "back room" or transition chamber allows the part to be moved from the main heating chamber into a quench tank (for rapid cooling) without ever being exposed to outside air. This prevents oxidation of the hot workpiece just before the critical quenching step.

Safety and Monitoring Systems

Many atmosphere gases are flammable or combustible. Therefore, these furnaces are equipped with advanced safety and explosion-proof devices. Sensor technology is also used to monitor the gas composition in real-time.

Understanding the Trade-offs

While powerful, controlled atmosphere furnaces introduce complexity and cost that aren't always necessary.

Cost and Complexity

The requirement for a perfectly sealed vessel, gas management systems, advanced safety features, and the cost of the process gases themselves makes atmosphere furnaces significantly more expensive to purchase and operate than their open-air counterparts.

Process Control Challenges

Maintaining a precise gas composition is a technical challenge. Success relies on accurate sensors and a deep understanding of the chemical reactions taking place. Incorrect assumptions about the atmosphere's potential can lead to parts that fail to meet their required specifications.

Making the Right Choice for Your Goal

Selecting the right heat treatment process depends entirely on the final requirements of the part.

- If your primary focus is preventing surface oxidation and scaling on sensitive parts: An inert atmosphere furnace provides the necessary protection.

- If your primary focus is increasing surface hardness and wear resistance: An active atmosphere furnace for processes like carburizing or nitriding is essential.

- If your primary focus is simple stress relief or annealing on non-critical parts: A standard, non-atmosphere box furnace is often the most cost-effective solution.

Ultimately, a controlled atmosphere furnace gives you command over the material's surface chemistry, ensuring the final product performs exactly as designed.

Summary Table:

| Purpose | Key Benefit | Typical Atmosphere Type |

|---|---|---|

| Prevent Oxidation/Scaling | Protects surface finish & dimensional accuracy | Inert (e.g., Nitrogen, Argon) |

| Increase Surface Hardness | Creates a hard, wear-resistant shell (e.g., carburizing) | Active (e.g., Endothermic gas) |

| Enable Specific Chemistry | Precisely controls surface carbon content for properties | Active with controlled carbon potential |

Ready to achieve precise metallurgical results with your heat treating?

At KINTEK, we specialize in high-performance lab equipment, including controlled atmosphere box furnaces designed for demanding applications. Whether you need to prevent oxidation on sensitive components or perform active processes like carburizing, our solutions provide the exact control you need.

We serve laboratories and manufacturers who require reliable, repeatable results. Let our experts help you select the right furnace for your specific goals.

Contact KINTEK today to discuss your heat treating challenges and discover the right controlled atmosphere solution for your lab.

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What are hydrogen furnaces used for? Achieve Purity and Speed in High-Temperature Processing

- What role does the reducing protective gas play in Cu-SiOC hybrid ceramics? Ensure Conductivity via Active Reduction

- What is nitrogen annealing in metalworking? Enhancing Ductility and Preventing Oxidation for High-Quality Components

- Why Is a Tube Atmosphere Furnace Required for Copper-Plated Graphite? Ensure Oxide-Free Interfacial Bonding

- What role does a high-temperature atmosphere furnace play in Al0.5CoCrFeNi HEAs? Optimize Phase & Microstructure

- What are the advantages of a sealed quench furnace? Achieve Superior Metallurgical Consistency & Efficiency

- What role does an inert gas-protected heating device play in 2024Al/Gr/SiC composite manufacturing?

- What are 3 uses of inert gases? Prevent Fires, Preserve Quality, and Ensure Purity