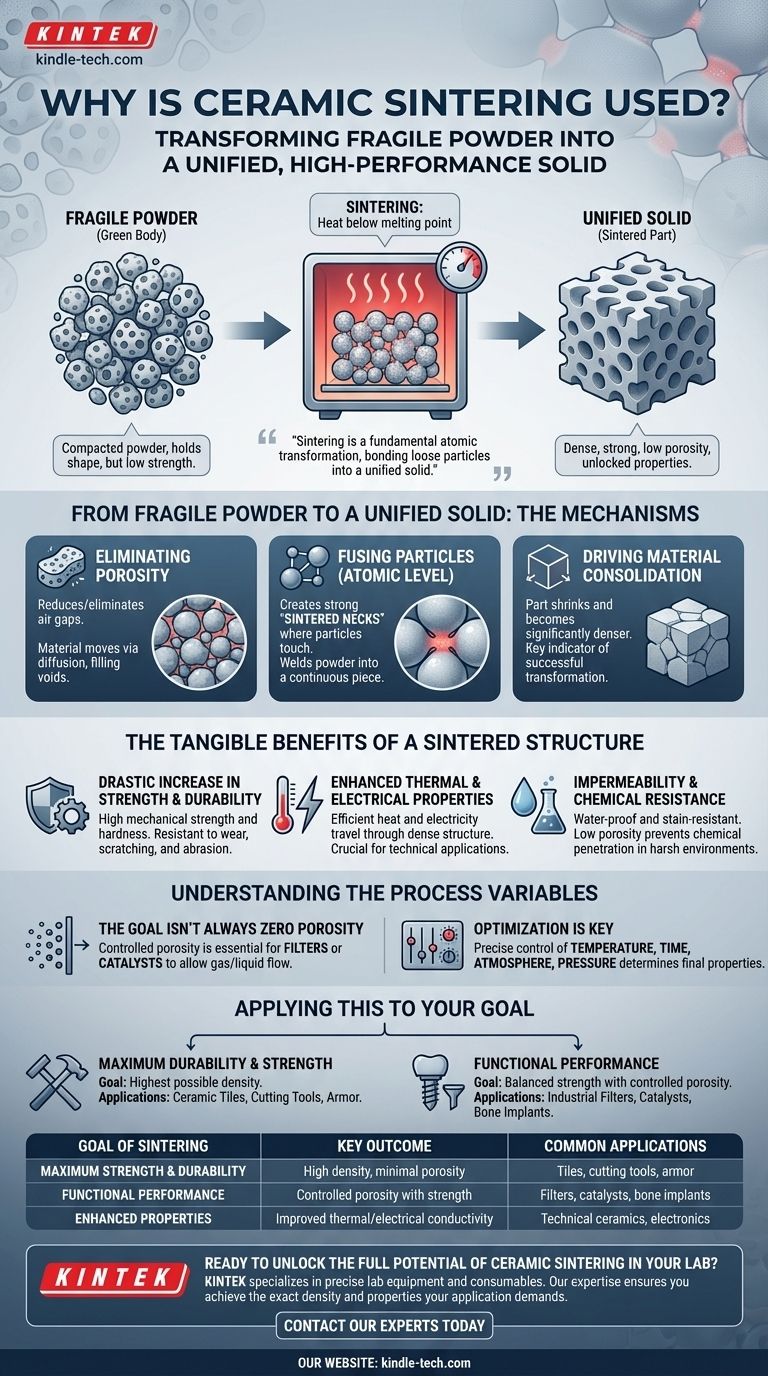

In short, ceramic sintering is used to transform a fragile, porous object made of compacted powder into a dense, strong, and solid final part. This is achieved by heating the material to a high temperature—below its melting point—which causes the individual ceramic particles to fuse, drastically reducing internal voids and unlocking the material's inherent properties.

Sintering is not merely a heating process; it is a fundamental transformation at the atomic level. It is the critical manufacturing step that bonds loose particles into a unified, high-performance solid, giving ceramic its signature strength and durability.

From Fragile Powder to a Unified Solid

A ceramic part before sintering, often called a "green body," is simply a compacted mass of powder. It holds its shape but has very little mechanical strength. Sintering fundamentally changes this structure.

Eliminating Porosity

The primary goal of sintering is to reduce or eliminate the tiny air gaps, or porosity, that exist between the particles in the green body.

As the ceramic is heated, material begins to move through diffusion, filling these voids and pulling the particles closer together.

Fusing Particles at the Atomic Level

This material movement creates strong atomic bonds, or "sintered necks," at the points where individual particles touch.

These necks grow over time at high temperatures, effectively welding the powder into a single, continuous piece. This process is the source of the final part's strength.

Driving Material Consolidation

As porosity is eliminated and particles fuse, the entire part shrinks and becomes significantly denser. This consolidation is a key indicator that the sintering process is successfully transforming the material's internal structure.

The Tangible Benefits of a Sintered Structure

The microstructural changes that occur during sintering directly translate into the highly desirable properties for which ceramics are known.

Drastic Increase in Strength and Durability

By eliminating pores, which act as stress concentration points, and fusing the particles, sintering dramatically increases the material's mechanical strength and hardness.

This makes the final product highly durable and resistant to scratching, abrasion from high traffic, and general wear.

Enhanced Thermal and Electrical Properties

A dense, non-porous structure allows heat and electricity to travel through the material more efficiently.

Sintering is therefore crucial for developing ceramics with specific thermal conductivity or electrical conductivity characteristics for technical applications.

Achieving Impermeability and Chemical Resistance

A fully sintered ceramic has very low or no interconnected porosity, making it water-proof and highly resistant to stains.

This lack of pores also prevents chemicals from penetrating the surface, contributing to its excellent performance in harsh environments and resistance to UV rays or extreme weather.

Understanding the Process Variables

Achieving the desired outcome is not automatic. The sintering process must be carefully controlled, as the goal is not always to achieve maximum possible density.

The Goal Isn't Always Zero Porosity

In some applications, a degree of controlled porosity is essential. For products like filters or catalysts, the objective is to create enough particle fusion to ensure strength while intentionally leaving a network of pores to allow for gas or liquid flow.

Optimization is Key

The final properties of a ceramic part are dictated by the sintering process parameters. Factors like temperature, time, furnace atmosphere, and the use of pressure must be precisely optimized to guarantee the desired outcome, whether it's maximum density or controlled porosity.

How to Apply This to Your Goal

The specific objective of the sintering cycle depends entirely on the intended application of the final product.

- If your primary focus is maximum durability and strength: The goal is to achieve the highest possible density, minimizing porosity for applications like ceramic tiles, cutting tools, or armor.

- If your primary focus is functional performance: The goal is to balance strength with a specific, controlled level of porosity for applications like industrial filters, catalyst supports, or bone implants.

Ultimately, sintering is the essential process that unlocks the vast potential of advanced ceramic materials.

Summary Table:

| Goal of Sintering | Key Outcome | Common Applications |

|---|---|---|

| Maximum Strength & Durability | High density, minimal porosity | Tiles, cutting tools, armor |

| Functional Performance | Controlled porosity with strength | Filters, catalysts, bone implants |

| Enhanced Properties | Improved thermal/electrical conductivity | Technical ceramics, electronics |

Ready to unlock the full potential of ceramic sintering in your lab?

KINTEK specializes in the precise lab equipment and consumables needed to perfect your sintering process. Whether you're developing high-strength components or functional porous materials, our expertise and reliable furnaces ensure you achieve the exact density and properties your application demands.

Contact our experts today to discuss how we can support your materials development goals.

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the role of a tube furnace in the thermal treatment of argyrodite electrolytes? Master Ionic Conductivity

- Why use quartz tubes and vacuum sealing for sulfide solid-state electrolytes? Ensure Purity & Stoichiometry

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses