Graphite is the material of choice for refractory crucibles because of its remarkable ability to withstand extreme heat without melting while also being an excellent conductor of heat. This unique combination, along with its chemical inertness, allows it to rapidly and cleanly melt metals and other materials without cracking or contaminating the final product.

The true value of graphite for crucibles lies not in a single trait, but in its rare ability to both withstand extreme temperatures and conduct heat efficiently without reacting with the substance it holds. This synergy ensures rapid, uniform, and pure melting processes.

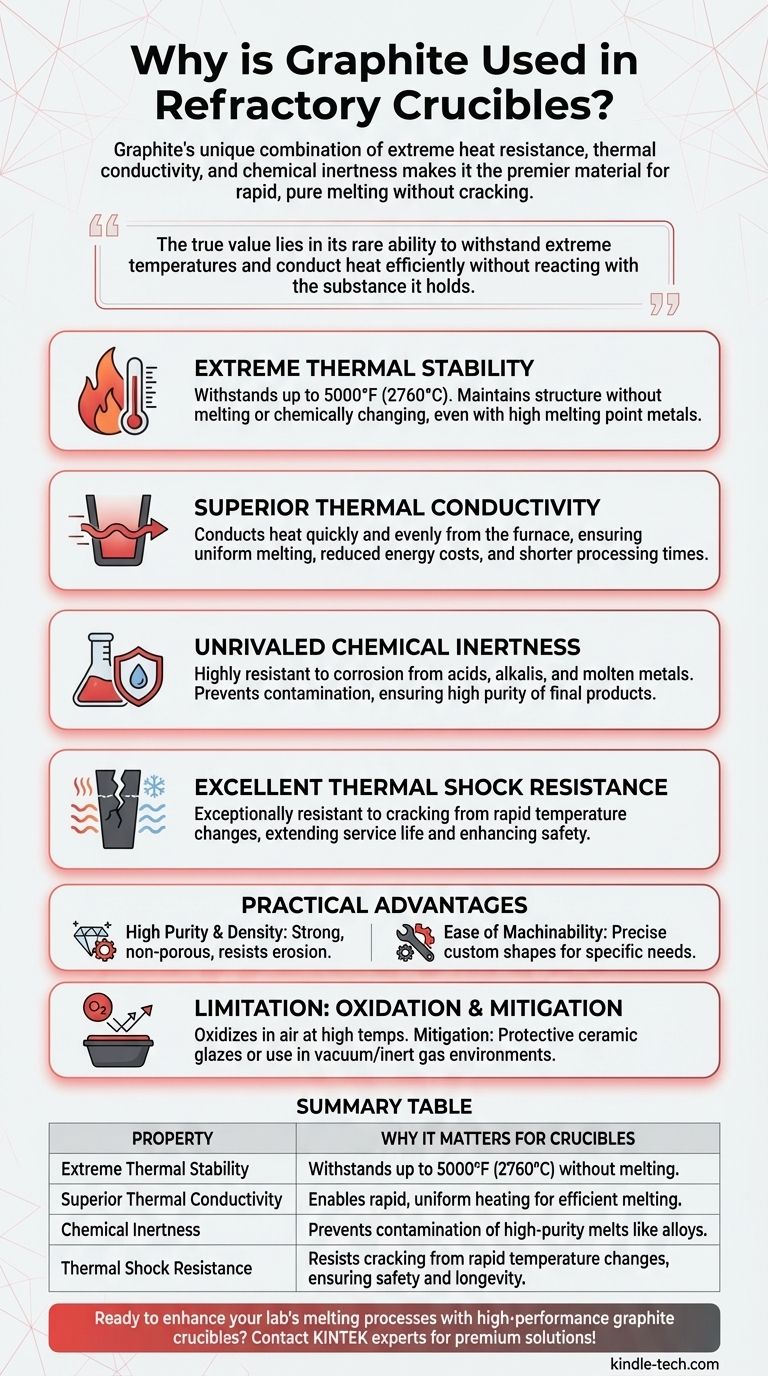

The Core Properties Driving Graphite's Performance

To understand why graphite is so dominant in high-temperature applications, we need to examine its fundamental material properties. Each one solves a critical problem faced in foundries and laboratories.

Extreme Thermal Stability

A crucible's primary function is to contain materials at temperatures that would destroy most containers. Graphite excels here, maintaining its structure and strength at temperatures up to 5000°F (around 2760°C).

This high sublimation point means the crucible itself will not melt, burn, or chemically change, even when holding metals with very high melting points like steel.

Superior Thermal Conductivity

Unlike ceramic materials which are often thermal insulators, graphite is a very good conductor of heat.

This property is crucial for efficiency. It allows heat from the furnace to transfer quickly and evenly through the crucible to the material inside, ensuring a uniform melt, reducing energy costs, and shortening processing times.

Unrivaled Chemical Inertness

When melting alloys or performing chemical analyses, purity is paramount. Graphite is chemically inert and highly resistant to corrosion from strong acids, alkalis, and the molten metals themselves.

This non-reactive nature ensures that the crucible does not leach impurities into the melt, which is essential for maintaining the quality and reliability of the final product, from precious metals to specialized alloys.

Excellent Thermal Shock Resistance

Thermal shock occurs when a material cracks due to rapid temperature changes, such as when a hot crucible is removed from a furnace.

Graphite's structure is exceptionally resistant to this stress. This durability translates to a longer service life and greater safety, as it can withstand repeated cycles of intense heating and cooling without failing.

Practical Advantages in Fabrication and Use

Beyond its core thermal and chemical properties, graphite offers tangible benefits that make it a practical and reliable choice.

High Purity and Density

Graphite for crucibles is manufactured to high purity standards. Combined with high density and a fine grain structure, this creates a strong, non-porous vessel that further resists chemical attack and physical erosion from molten materials.

Ease of Machinability

Despite its strength, graphite is relatively easy to machine with high precision. This allows for the creation of a wide variety of crucible shapes and sizes, as well as complex molds and casting components tailored to specific industrial needs.

A Key Limitation: Oxidation

While nearly ideal, graphite has one significant vulnerability that users must manage. This objectivity is key to using the material successfully.

The Impact of Atmosphere

Graphite does not melt, but it will oxidize (essentially burn away) in the presence of oxygen at high temperatures. This can degrade the crucible over time, reducing its wall thickness and shortening its lifespan.

Mitigation Strategies

For this reason, graphite crucibles often feature a protective ceramic glaze to shield them from oxygen. In the most demanding applications, they are used within vacuum furnaces or environments filled with an inert gas to prevent oxidation entirely.

Making the Right Choice for Your Application

Your choice of crucible material must align with the specific demands of your process. Understanding graphite's strengths and weaknesses is key to proper selection.

- If your primary focus is rapid, high-temperature melting: Graphite's unparalleled thermal conductivity and stability make it the superior choice for efficiency.

- If your primary focus is purity for alloys or lab work: Graphite's chemical inertness is essential to prevent contamination of your sample.

- If you are working in an open-air furnace: Be mindful of graphite's oxidation and select a crucible with a protective glaze to ensure a reasonable service life.

By understanding these core principles, you can confidently leverage graphite's unique properties for reliable, high-performance results.

Summary Table:

| Property | Why It Matters for Crucibles |

|---|---|

| Extreme Thermal Stability | Withstands temperatures up to 5000°F (2760°C) without melting. |

| Superior Thermal Conductivity | Enables rapid, uniform heating for efficient melting. |

| Chemical Inertness | Prevents contamination of high-purity melts like alloys. |

| Thermal Shock Resistance | Resists cracking from rapid temperature changes, ensuring safety and longevity. |

Ready to enhance your lab's melting processes with high-performance graphite crucibles? KINTEK specializes in premium lab equipment, including a full range of graphite crucibles designed for superior thermal performance and purity. Our products ensure efficient, contamination-free results for your most demanding applications. Contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- High Purity Pure Graphite Crucible for Evaporation

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- Why are stainless steel reactors and graphite crucibles used for Nb-Ti alloys? Ensuring Purity in Magnesiothermic Reduction

- Why are Boron Nitride (BN) or Alumina crucibles preferred for Na-flux GaN growth? Optimize Your Crystal Yield

- Will stainless steel work as a crucible? The Surprising Dangers of Using the Wrong Material

- Can a crucible withstand high temperature? Selecting the Right Material for Extreme Heat

- Why is a ceramic crucible essential for ZrCu-based master alloys? Ensuring Purity and Thermal Stability

- What are the advantages of using alumina (corundum) crucibles in vitrification? Ensure Pure, High-Temp Results

- Why is a graphite crucible selected for melting Copper-Silver (Cu-Ag) alloys? Achieve High-Purity Results

- What is the purpose of using a platinum crucible in LAGP synthesis? Ensure Purity in High-Temperature Reactions