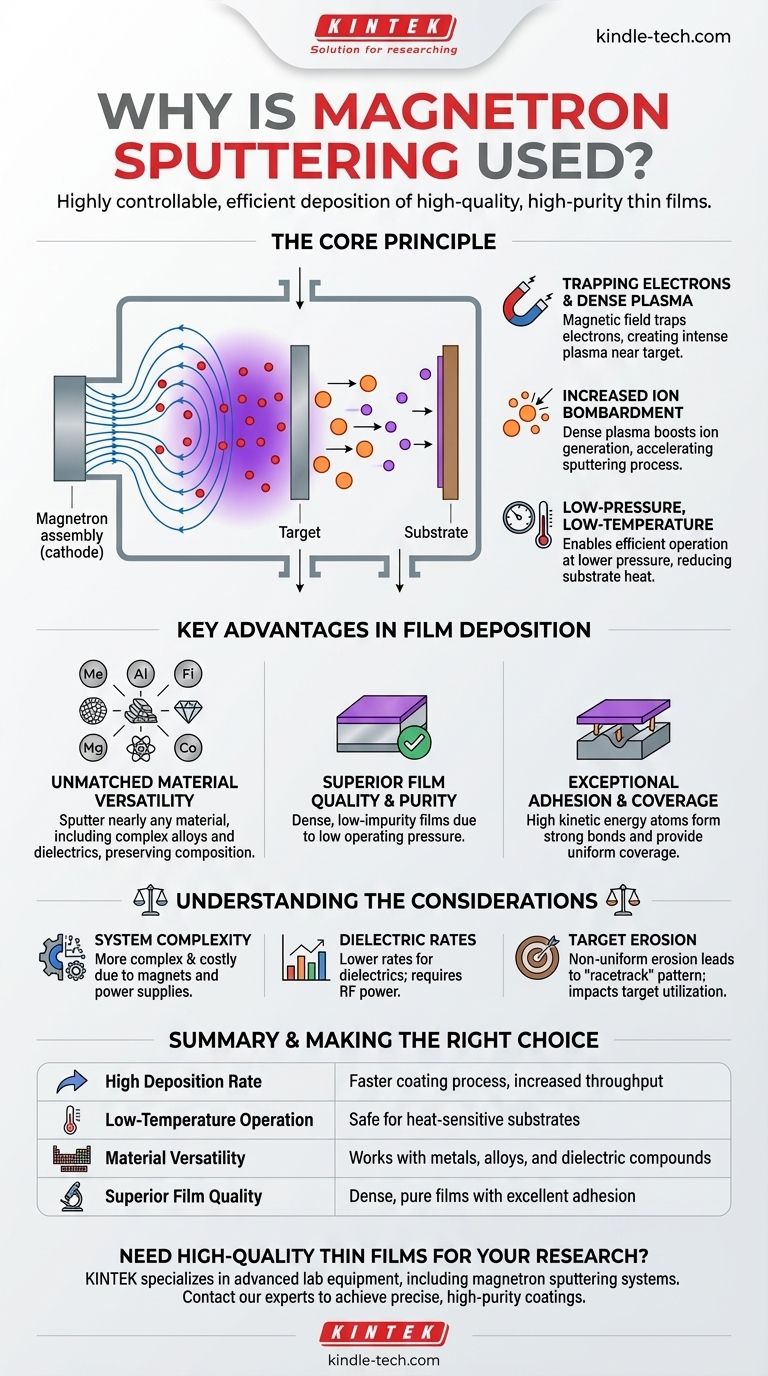

At its core, magnetron sputtering is used because it is a highly controllable and efficient method for depositing high-quality, high-purity thin films onto a surface. It achieves faster deposition rates at lower temperatures and pressures than conventional sputtering, and it works with a vast range of materials, including metals, alloys, and compounds.

The essential advantage of magnetron sputtering is its strategic use of magnetic fields to trap electrons and concentrate plasma near the target material. This dramatically boosts the efficiency of the sputtering process, enabling the creation of denser, purer, and more adhesive films without damaging the underlying substrate.

The Core Principle: How Magnets Revolutionize Sputtering

To understand why magnetron sputtering is so dominant, you must first understand the role of the magnets. They solve the key inefficiencies of basic sputtering techniques.

Trapping Electrons to Create Dense Plasma

The magnetron assembly, located behind the target material (cathode), generates a magnetic field. This field traps free electrons and forces them into a spiral path directly in front of the target's surface.

This cloud of trapped electrons creates a dense, intense plasma precisely where it's needed most.

Increasing Ion Bombardment Efficiency

The dense electron plasma is highly effective at ionizing neutral gas atoms (typically argon). This creates a much higher concentration of positive ions.

These ions are then accelerated into the target, striking it with force and dislodging atoms—the sputtering process. The increased ion bombardment directly results in a much higher deposition rate.

Enabling Low-Pressure, Low-Temperature Operation

Because the plasma is magnetically confined and intensified, the process can run efficiently at much lower gas pressures.

Furthermore, the magnetic field prevents most high-energy electrons from bombarding the substrate. This significantly reduces heat transfer, allowing for the coating of heat-sensitive materials like plastics without causing damage.

Key Advantages in Film Deposition

The unique physics of the magnetron process translates into a series of practical advantages that produce superior thin films for countless applications.

Unmatched Material Versatility

One of the most significant benefits is the ability to sputter nearly any material. This includes high-melting-point metals, complex alloys, and even dielectric compounds.

The process does not require melting or evaporating the source material, allowing it to deposit films of alloys or compounds while perfectly preserving their original chemical composition.

Superior Film Quality and Purity

Magnetron sputtering produces films that are incredibly dense and have very low levels of impurities.

The low operating pressure means fewer gas atoms are incorporated into the growing film, resulting in a higher-purity final product.

Exceptional Adhesion and Coverage

Atoms ejected from the target have high kinetic energy. This energy helps them form an extremely strong bond with the substrate surface, leading to excellent film adhesion.

The process also provides excellent, uniform coverage, even over substrates with small or complex surface features.

Understanding the Trade-offs and Considerations

While powerful, magnetron sputtering is not a universal solution. An objective assessment requires understanding its operational context.

System Complexity

The introduction of magnets and the required power supplies (DC for metals, RF for dielectrics) makes a magnetron sputtering system more complex and costly than simpler methods like thermal evaporation.

Deposition Rates for Dielectrics

While the process is versatile, deposition rates for insulating materials (dielectrics) are typically lower than those for conductive metals. This is due to the need for RF power, which is less efficient than the DC power used for metals.

Target Material and Geometry

The magnetic field concentrates the plasma in a specific region, leading to non-uniform erosion of the target material, often in a "racetrack" pattern. This means that target material utilization is not 100%, and target design is an important consideration for process efficiency.

Making the Right Choice for Your Goal

Selecting this method depends entirely on your project's specific requirements for quality, material, and substrate.

- If your primary focus is high-throughput industrial coating: The combination of high deposition rates, scalability, and excellent uniformity over large areas makes it the ideal choice.

- If your primary focus is depositing complex alloys or compounds: This method excels because it preserves the material's original stoichiometry in the final film.

- If your primary focus is research on sensitive substrates or creating high-purity films: Its low-temperature operation and the high density and purity of the resulting films provide critical advantages.

Ultimately, magnetron sputtering is chosen for its unparalleled combination of control, quality, and material versatility in engineering surfaces at the atomic level.

Summary Table:

| Key Advantage | Why It Matters |

|---|---|

| High Deposition Rate | Faster coating process, increased throughput |

| Low-Temperature Operation | Safe for heat-sensitive substrates like plastics |

| Material Versatility | Works with metals, alloys, and dielectric compounds |

| Superior Film Quality | Dense, pure films with excellent adhesion and coverage |

Need to deposit a high-quality thin film for your research or production? KINTEK specializes in providing advanced lab equipment, including magnetron sputtering systems, to meet your specific material and substrate requirements. Our experts can help you achieve the precise, high-purity coatings your work demands. Contact our team today to discuss your project and find the ideal solution!

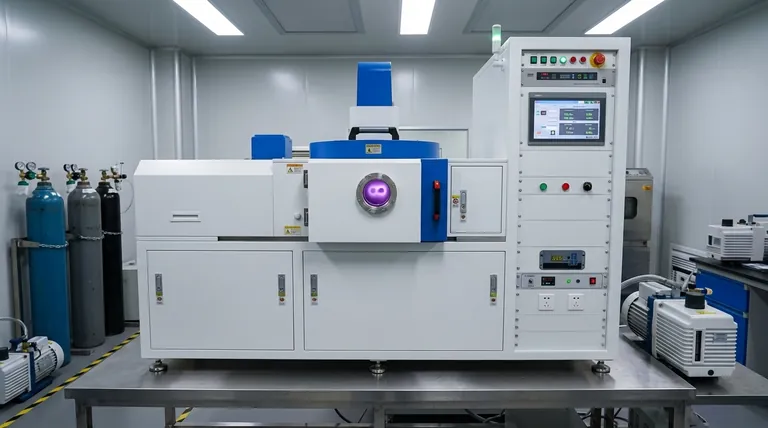

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings