In short, press forging is used for large components because its slow, controlled application of immense force ensures the deformation penetrates through the entire thickness of the workpiece. This creates a uniform internal grain structure and mechanical properties, which is something the rapid, surface-level impact of a hammer cannot achieve on a massive scale.

The fundamental challenge in forging large parts isn't just achieving the external shape, but guaranteeing the material's integrity deep within its core. Press forging solves this by trading the high-speed impact of a hammer for slow, sustained pressure that uniformly works the entire metal volume.

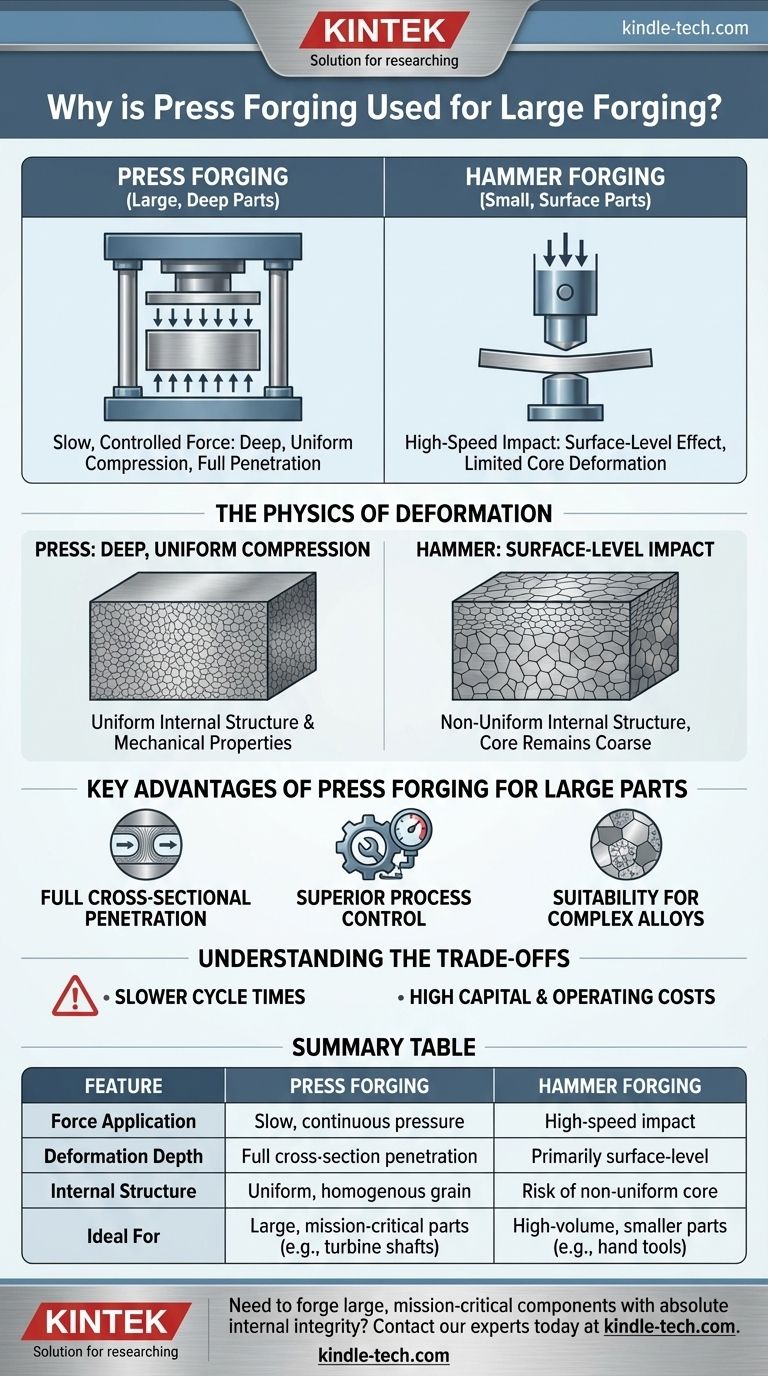

The Physics of Deformation: Press vs. Hammer

To understand why presses are superior for large forgings, we must first examine how force is applied in the two primary forging methods: presses and hammers.

The Press: Deep, Uniform Compression

A forging press, whether hydraulic or mechanical, acts like a giant, powerful vise. It applies continuous and controlled pressure on the workpiece.

This slow squeeze is critical. It gives the metal time to flow and plastically deform throughout its entire cross-section, from the surface to the very center.

The result is a homogenous grain structure and consistent density, which is essential for the performance and safety of high-stress components like turbine shafts or aircraft landing gear.

The Hammer: Surface-Level Impact

A forging hammer works on the principle of kinetic energy. It delivers a massive amount of energy in a very short time through a high-velocity impact.

For smaller parts, this is highly effective. However, on a very large and thick workpiece, the impact energy tends to dissipate at the surface. It does not have the time or sustained force needed to penetrate and work the material at its core.

This can create a non-uniform internal structure, where the surface grains are refined but the core remains coarse. This inconsistency is unacceptable for critical, large-scale applications.

Key Advantages of Press Forging for Large Parts

The physical principle of deep deformation gives press forging several practical advantages when working with massive components.

Full Cross-Sectional Penetration

The defining benefit is the ability to achieve full deformation through thick sections of metal. The reference to presses with capacities up to 100,000 tons highlights the immense force required to slowly move that much material.

This ensures the final product has predictable and uniform mechanical properties, eliminating the internal weak points that could lead to catastrophic failure under load.

Superior Process Control

Hydraulic presses offer unparalleled control over ram speed and pressure throughout the stroke. This precision is vital when forging complex, high-value parts where dimensional accuracy and a flawless internal structure are non-negotiable.

Suitability for Complex Alloys

Many large forgings are made from advanced alloys (like titanium or nickel superalloys) that are sensitive to temperature and deformation rate. The slow, controlled nature of press forging is ideal for working these materials without causing cracks or other defects.

Understanding the Trade-offs

While superior for large parts, press forging is not the universal solution. Its advantages come with clear disadvantages in other contexts.

Slower Cycle Times

The primary trade-off is speed. A press forges deliberately and slowly, making its cycle time significantly longer than that of a hammer.

This makes press forging less economical for the high-volume production of smaller, simpler components where speed is a primary cost driver.

High Capital Investment and Operating Costs

The machinery itself is a major factor. Hydraulic presses capable of generating forces in the tens of thousands of tons are monumental, complex, and extremely expensive to build, install, and maintain.

Their operation also consumes vast amounts of energy to generate and sustain the required hydraulic pressures over the course of the forging stroke.

Making the Right Choice for Your Goal

The decision to use a press or a hammer is dictated by the size of the component and the required internal quality.

- If your primary focus is producing large, mission-critical components (e.g., aerospace frames, power generation rotors, large valve bodies): Press forging is the required method to ensure deep, uniform material properties.

- If your primary focus is high-volume production of smaller parts (e.g., hand tools, standard automotive components): Hammer forging offers the speed and cost-effectiveness needed for mass production.

- If you need to forge complex, moderate-sized parts that require more control than a hammer can offer: A mechanical press can provide a faster-acting alternative to a hydraulic press, bridging the gap between the two extremes.

Ultimately, the choice between forging methods hinges on whether your priority is the absolute internal integrity of a large part or the production speed of a smaller one.

Summary Table:

| Feature | Press Forging | Hammer Forging |

|---|---|---|

| Force Application | Slow, continuous pressure | High-speed impact |

| Deformation Depth | Full cross-section penetration | Primarily surface-level |

| Internal Structure | Uniform, homogenous grain | Risk of non-uniform core |

| Ideal For | Large, mission-critical parts (e.g., turbine shafts) | High-volume, smaller parts (e.g., hand tools) |

Need to forge large, mission-critical components with absolute internal integrity?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to support the development and quality control of high-performance forged parts. Whether you're in aerospace, energy, or heavy manufacturing, our solutions help ensure your materials meet the highest standards.

Contact our experts today to discuss how we can support your forging and material testing requirements.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- What is the ratio of KBr and sample in IR? Achieve Perfect Sample Concentration for Clear IR Spectra

- What role does a laboratory hydraulic press play in pellet-type electrode fabrication? Enhancing Solid-State Performance

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is an example of a hydraulic press? Discover the Power of Laboratory Sample Preparation