In short, Physical Vapor Deposition (PVD) is performed in a high vacuum to ensure the vaporized coating material can travel from its source to the part being coated without colliding with or reacting to air particles. This vacuum creates a controlled environment, which is essential for creating a pure, dense, and well-adhering coating.

The use of a vacuum is not merely about removing air; it is about achieving absolute control. By creating an ultra-clean environment, operators can either deposit a completely pure material or intentionally introduce specific gases to engineer a new compound with precise properties.

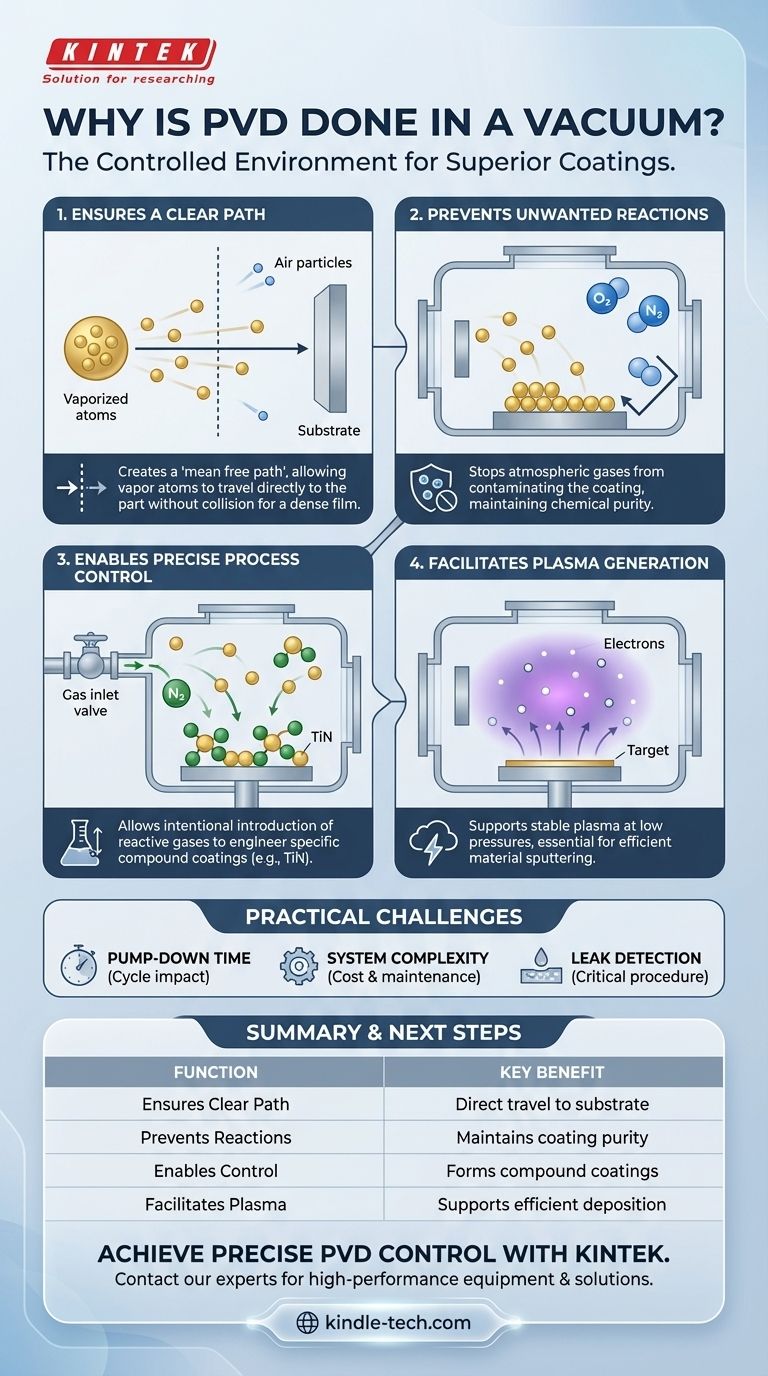

The Core Functions of the Vacuum Environment

A high-vacuum chamber is the defining feature of any PVD system. Each function of the vacuum is critical to transforming a raw material into a high-performance coating.

Ensuring a Clear Path for Deposition

The primary physical purpose of the vacuum is to remove obstacles. An atmosphere at sea level contains billions of trillions of air particles in every cubic centimeter.

Vaporized coating atoms are incredibly small and would collide with these air particles almost instantly. These collisions scatter the coating atoms, reduce their energy, and prevent them from reaching the substrate with enough force to form a dense film.

By creating a vacuum, we reduce the density of these background particles, creating a "mean free path"—the average distance a coating atom can travel before hitting something—that is longer than the distance from the source to the substrate. This ensures a direct, line-of-sight journey.

Preventing Unwanted Chemical Reactions

Air is composed primarily of nitrogen and oxygen, with traces of water vapor. These gases are highly reactive, especially with the hot, energetic atoms produced during PVD.

Without a vacuum, the coating material would immediately react with these atmospheric gases. For example, a pure titanium coating would become a contaminated mix of titanium oxides and nitrides.

This contamination severely degrades the desired properties of the coating, such as its hardness, color, conductivity, and corrosion resistance. The vacuum ensures the final film is chemically pure and possesses the intended characteristics.

Enabling Precise Process Control

While a vacuum prevents unwanted reactions, it also provides the clean slate needed for wanted reactions. This is the basis of reactive PVD.

After achieving a high vacuum, operators can introduce a specific, high-purity process gas in precisely controlled amounts. For example, introducing nitrogen into the chamber during titanium deposition creates a hard, gold-colored Titanium Nitride (TiN) coating.

This level of control over the chamber's atmosphere allows for the creation of a vast range of ceramic and compound coatings (oxides, nitrides, carbides) that would be impossible to form otherwise.

Facilitating Plasma Generation

Many PVD methods, especially sputtering, rely on the generation of a plasma. A plasma is a state of matter where a gas is ionized, creating a mix of ions and electrons.

Achieving and sustaining a stable plasma is only possible at low pressures. The vacuum allows electrons to travel far enough and gain enough energy to effectively ionize the process gas (typically Argon), which then sputters the coating material from the target.

Understanding the Practical Implications

While essential, the requirement for a high vacuum introduces significant challenges and costs to the PVD process.

The Impact on Cycle Time

Achieving a high vacuum is not instantaneous. The "pump-down" time can be a significant portion of the total process cycle.

During this phase, pumps work to remove air while heaters are often used to bake the chamber walls and fixtures. This heating helps drive off adsorbed water vapor, a major contaminant that can otherwise slowly "outgas" and compromise the vacuum level.

The Cost and Complexity of Vacuum Systems

High-vacuum equipment—including chambers, seals, and advanced pumps like turbomolecular or cryogenic pumps—is expensive to purchase and maintain.

These systems add significant mechanical and electrical complexity. Operators require specialized training to run the equipment and diagnose issues like vacuum leaks.

The Criticality of Leak Detection

Even a microscopic leak in the vacuum chamber can continuously introduce atmospheric gases, contaminating the process and ruining the coating batch.

Constant monitoring of vacuum levels and periodic leak detection using tools like a helium leak detector are standard, critical procedures in any professional PVD operation.

Applying This Understanding to Your Process

Your specific goal will determine which aspect of the vacuum environment is most critical to your success.

- If your primary focus is depositing a pure metal film: The vacuum is your guarantee of purity, preventing the formation of unwanted oxides or nitrides that degrade performance.

- If your primary focus is creating a compound coating (like TiN): The vacuum provides the clean slate needed to introduce a precise amount of reactive gas, giving you full control over the film's stoichiometry and properties.

- If your primary focus is process efficiency and throughput: You must balance the need for a deep vacuum against the pump-down time, as this directly impacts your operational cycle and cost per part.

Ultimately, the vacuum in PVD is the fundamental enabler of control, transforming the process from an unpredictable reaction into a precise engineering discipline.

Summary Table:

| Function of Vacuum | Key Benefit |

|---|---|

| Ensures Clear Path for Deposition | Creates a long mean free path for vaporized atoms to travel directly to the substrate. |

| Prevents Chemical Reactions | Avoids contamination from air (oxygen, nitrogen, water vapor) to maintain coating purity. |

| Enables Process Control | Allows intentional introduction of reactive gases (e.g., nitrogen) to form compound coatings like TiN. |

| Facilitates Plasma Generation | Supports stable plasma formation in methods like sputtering for efficient material deposition. |

Ready to achieve superior coating results with precise vacuum control? KINTEK specializes in high-performance PVD equipment and consumables, designed to meet the exacting demands of laboratory and industrial coating processes. Whether you need to deposit pure metals or engineer advanced compound films, our solutions ensure purity, adhesion, and repeatability. Contact our experts today to discuss how we can optimize your PVD operations!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method