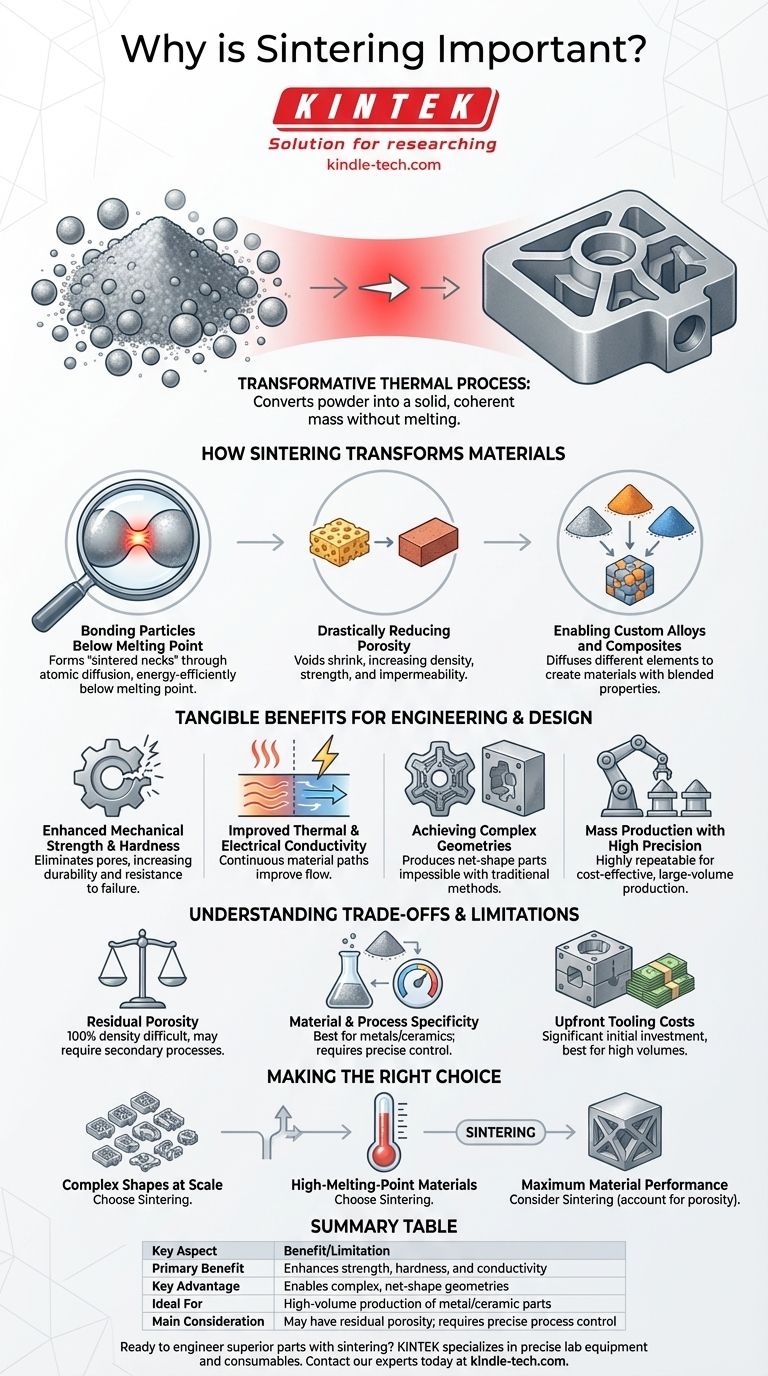

At its core, sintering is a transformative thermal process used to convert a powdered material into a solid, coherent mass without melting it. Its importance lies in its unique ability to fundamentally enhance a material's properties—such as strength, conductivity, and density—while simultaneously enabling the cost-effective mass production of complex geometric parts that are difficult or impossible to create with other methods.

Sintering’s true value is not just in making parts, but in engineering their final properties. By bonding particles at a microscopic level, it provides a powerful, energy-efficient method to create high-performance components from a wide range of materials, including metals and ceramics with extremely high melting points.

How Sintering Fundamentally Transforms Materials

Sintering is not simply a heating process; it's a controlled atomic and microstructural event. It works by heating a compacted powder to a temperature high enough to cause atoms to diffuse across the boundaries of the particles, fusing them together.

Bonding Particles Below Melting Point

The primary mechanism of sintering is the formation of sintered necks, or bonds, between adjacent particles. This diffusion process occurs at temperatures below the material's melting point, making it exceptionally energy-efficient.

This is especially critical for materials with very high melting points, like tungsten or molybdenum, which would be impractical and expensive to process by melting and casting.

Drastically Reducing Porosity

The initial compacted powder, often called a "green part," is highly porous. As sintering progresses, the necks between particles grow and the voids between them shrink and close up.

This reduction in porosity is directly responsible for increasing the material's density. A denser part is inherently stronger and less permeable.

Enabling Custom Alloys and Composites

Sintering allows for the diffusion of different elements throughout the part. You can mix powders of different materials, such as iron, graphite, and copper, to create a final part with blended properties.

This process allows for the creation of unique alloys and metal matrix composites, combining attributes like hardness with toughness or high strength with self-lubricating properties.

The Tangible Benefits for Engineering and Design

The microscopic changes from sintering translate directly into macroscopic advantages that engineers and designers can leverage.

Enhanced Mechanical Strength and Hardness

By eliminating pores, which are natural stress concentration points, sintering dramatically improves a part's strength, hardness, and overall integrity. The resulting component is far more durable and resistant to failure than its original powdered form.

Improved Thermal and Electrical Conductivity

Pores and air gaps are excellent insulators. By fusing particles together and reducing these gaps, sintering creates a more continuous path for heat and electricity to flow. This directly improves the thermal and electrical conductivity of the material.

Achieving Complex Geometries

Sintering allows for the production of intricate, net-shape or near-net-shape parts directly from a mold. This enables non-machinable geometries and complex internal features that would be prohibitively expensive or impossible to create using traditional subtractive manufacturing.

Mass Production with High Precision

Once the tooling is created, the sintering process is highly repeatable and accurate, making it ideal for cost-effective production of large volumes of identical parts. The resulting components often have excellent surface finishes, minimizing the need for secondary processing.

Understanding the Trade-offs and Limitations

While powerful, sintering is not a universal solution. Understanding its limitations is crucial for making an informed decision.

Residual Porosity is a Factor

While sintering significantly reduces porosity, achieving 100% density is difficult and often requires secondary processes like Hot Isostatic Pressing (HIP). The presence of even small amounts of residual porosity can impact the ultimate mechanical properties compared to a fully wrought or forged part.

Material and Process Specificity

Sintering is best suited for materials that can be produced in powdered form, primarily metals and ceramics. The specific time, temperature, and atmosphere of the sintering cycle must be precisely controlled and optimized for each specific material and desired outcome.

Upfront Tooling Costs

For powder metallurgy applications, the cost of creating the initial molds (dies) can be significant. This makes sintering most cost-effective for high-volume production runs where the tooling cost can be amortized over thousands or millions of parts. For one-off or low-volume parts, methods like 3D printing (which often uses a form of sintering) may be more suitable.

Making the Right Choice for Your Application

Choosing sintering depends entirely on your project's specific constraints and performance requirements.

- If your primary focus is manufacturing complex shapes at scale: Sintering is an exceptional choice for producing intricate, repeatable parts that are difficult or costly to machine.

- If your primary focus is working with high-melting-point materials: Sintering provides a uniquely energy-efficient path to create dense, solid parts without the extreme temperatures required for melting.

- If your primary focus is maximum material performance: Sintering dramatically improves properties, but you must account for potential residual porosity and may need to couple it with secondary processes for the most demanding applications.

Ultimately, understanding sintering gives you a powerful tool for designing and manufacturing parts where both the material properties and the geometry are engineered for a precise purpose.

Summary Table:

| Key Aspect | Benefit/Limitation |

|---|---|

| Primary Benefit | Enhances strength, hardness, and conductivity |

| Key Advantage | Enables complex, net-shape geometries |

| Ideal For | High-volume production of metal/ceramic parts |

| Main Consideration | May have residual porosity; requires precise process control |

Ready to engineer superior parts with sintering? KINTEK specializes in the precise lab equipment and consumables needed to master this transformative thermal process. Whether you're working with high-melting-point metals or complex ceramic components, our solutions help you achieve the desired density and material properties. Contact our experts today to discuss how we can support your laboratory's sintering and material science needs.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations

- What is the mode of failure most often associated with ceramic dental implants? Understanding Fracture Risk

- What temperature is a dental sintering furnace? Mastering the Material-Specific Thermal Cycle

- What is the firing temperature of dental ceramics? A Guide to Precise Thermal Processing

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow