In ceramic processing, sintering is the critical step that transforms a fragile, porous powder compact into a dense, strong, and functional component. Through a precise application of high heat, it fundamentally alters the material's microstructure, fusing individual particles together to achieve the desired final properties of the finished part.

A pressed ceramic part, known as a "green body," is mechanically weak and full of voids. Sintering is the essential thermal treatment that eliminates this porosity, causing the particles to bond and densify, thereby creating a robust, high-performance ceramic.

From Powder to Solid: The Transformation of Sintering

Sintering is the bridge between a loosely-formed shape and a finished, engineered part. It's a process of densification that occurs at the atomic level.

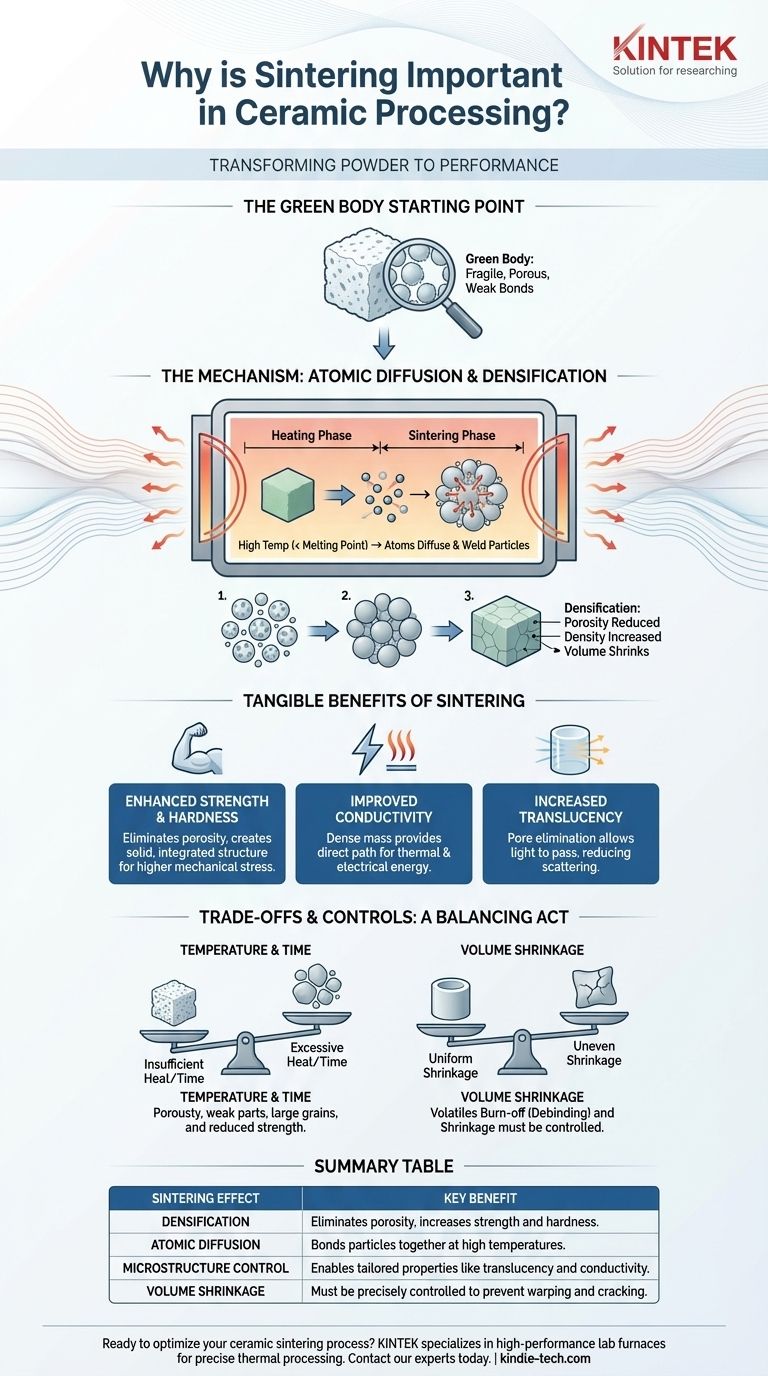

The "Green Body" Starting Point

Before sintering, ceramic powder is compacted under pressure into a desired shape. This initial object, called a green body, is chalk-like and fragile, held together only by weak mechanical bonds. It is characterized by high porosity, meaning it contains a significant volume of empty space between particles.

The Mechanism of Sintering: Atomic Diffusion

The green body is placed in a furnace and heated to a high temperature, typically below the material's melting point. At this elevated temperature, atoms gain enough energy to diffuse across the boundaries of adjacent particles. This material transfer effectively welds the particles together.

The Structural Result: Densification

As atoms move to fill the voids, the pores within the material shrink and are gradually eliminated. This process results in three key physical changes:

- Porosity is drastically reduced.

- Density is significantly increased.

- The entire part shrinks in volume.

The final result is a hard, dense, polycrystalline body with a specific microstructure, which dictates its final properties.

The Tangible Benefits of Sintering

By transforming the ceramic's internal structure, sintering directly improves its performance characteristics in several crucial ways.

Enhanced Mechanical Strength and Hardness

The primary benefit of sintering is a massive increase in strength and hardness. By eliminating pores, which act as microscopic points of failure, the process creates a solid, integrated structure that can withstand much higher mechanical stress.

Improved Thermal and Electrical Conductivity

Porosity inhibits performance. The air-filled voids in an unsintered green body are poor conductors of heat and electricity. By creating a dense, solid mass, sintering provides a more direct path for thermal and electrical energy to travel, improving conductivity.

Increased Translucency

For certain technical ceramics, like those used in dental implants or transparent armor, translucency is a key property. Pores scatter light, making a material opaque. The elimination of these pores during sintering allows light to pass through with less obstruction, dramatically increasing translucency.

Understanding the Trade-offs and Controls

Sintering is not a simple baking process; it is a highly controlled engineering step with critical variables and potential pitfalls.

The Balancing Act of Temperature and Time

The properties of the final part are dictated by the sintering temperature and duration. Insufficient heat or time will result in incomplete densification and a porous, weak part. Conversely, excessive heat or time can cause grains to grow too large, which can actually reduce the material's final strength.

The Risk of Warping and Cracking

The volume shrinkage that occurs during sintering is unavoidable and must be accounted for in the initial design of the green body. If heating, cooling, or the part's initial density is uneven, this shrinkage can create internal stresses, leading to warping, distortion, or cracking in the final component.

Removing Volatiles

The initial heating phase of the sintering cycle also serves to burn off binders, lubricants, or other volatile components used during the pressing stage. This "debinding" must be done carefully to prevent defects in the final part.

Optimizing Sintering for Your Goal

The parameters of the sintering process must be carefully tuned to achieve a specific outcome. This is where process control becomes paramount.

- If your primary focus is maximum strength and durability: You must aim for the highest possible density by optimizing temperature and time to minimize residual porosity.

- If your primary focus is creating a translucent ceramic: The key is eliminating nearly all pores, as they are the primary cause of light scattering and opacity.

- If your primary focus is precise final dimensions: You must carefully control powder characteristics and the sintering cycle to achieve consistent and predictable shrinkage.

Ultimately, mastering the sintering process is the key to engineering a ceramic component with predictable, reliable, and optimized performance.

Summary Table:

| Sintering Effect | Key Benefit |

|---|---|

| Densification | Eliminates porosity, increases strength and hardness. |

| Atomic Diffusion | Bonds particles together at high temperatures. |

| Microstructure Control | Enables tailored properties like translucency and conductivity. |

| Volume Shrinkage | Must be precisely controlled to prevent warping and cracking. |

Ready to optimize your ceramic sintering process? KINTEK specializes in high-performance lab furnaces and consumables designed for precise thermal processing. Our equipment ensures consistent results, from debinding to final densification, helping you achieve the exact mechanical, thermal, and optical properties you need. Contact our experts today to discuss how we can support your laboratory's ceramic processing goals.

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why ceramics can withstand high temperature? Unlock the Secrets of Atomic Structure

- What is dry ashing in a muffle furnace? A Guide to Precise Mineral Analysis

- Why refractory materials are used in furnaces? Ensure Safety, Efficiency, and Process Purity

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- How is metal purity measured? Understand Karats, Fineness & Percentage for Gold & Silver