In metal casting, temperature is not just a variable; it is the primary control mechanism for the entire process. Precise temperature management is essential for successfully melting the metal, ensuring it flows completely into the mold, and managing its solidification to prevent defects. The final integrity, strength, and quality of the cast part are all direct results of how well temperature is controlled.

The success of a casting hinges on a precise thermal balancing act. The pouring temperature must be high enough to ensure complete mold filling but controlled enough to minimize defects like shrinkage, gas porosity, and poor grain structure that arise from excessive heat and uncontrolled cooling.

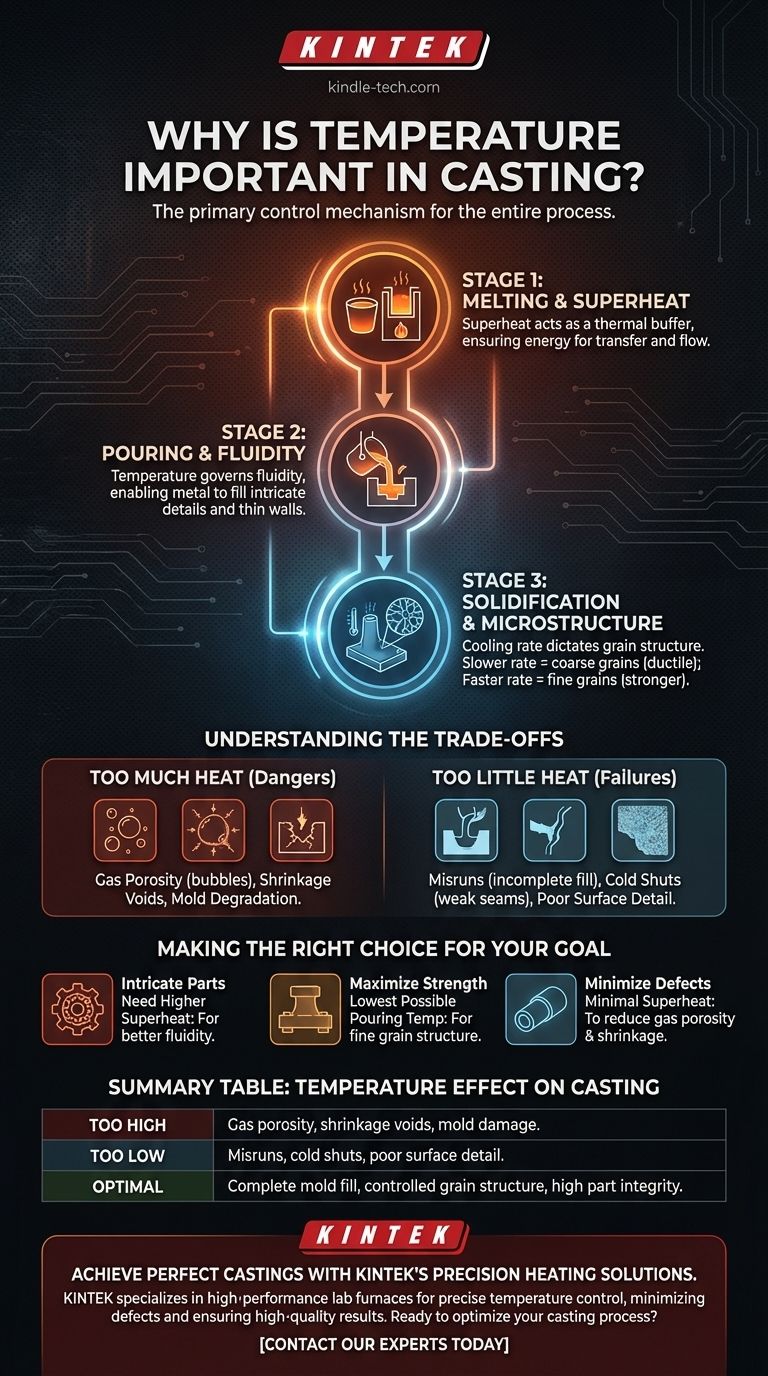

The Role of Temperature at Each Stage

To understand the importance of temperature, we must look at its role during the three critical stages of casting: melting, pouring, and solidification. Each stage has a different thermal requirement.

Stage 1: Melting and Superheat

Before pouring, metal must not only be melted but heated to a temperature significantly above its melting point. This additional heat is known as superheat.

Superheat acts as a thermal buffer. It ensures the liquid metal has enough energy to withstand temperature loss as it's transferred from the furnace to the mold and flows through the gating system without freezing prematurely.

Stage 2: Pouring and Fluidity

Temperature directly governs the fluidity of the molten metal—its ability to flow and fill intricate details within the mold cavity.

Higher superheat results in better fluidity, which is crucial for producing thin-walled or complex parts. Insufficient temperature and fluidity are a primary cause of casting failures.

Stage 3: Solidification and Microstructure

The final properties of the cast part are determined during solidification. The cooling rate—the speed at which the metal loses heat to the surrounding mold—is dictated by the initial pouring temperature.

This cooling rate directly controls the final grain structure of the metal. A slower cooling rate creates large, coarse grains, often resulting in a softer, more ductile part. A faster cooling rate produces small, fine grains, which typically leads to a stronger but more brittle part.

Understanding the Trade-offs: The Dangers of Incorrect Temperatures

Achieving the right temperature is a balancing act. Deviating too far in either direction introduces significant risk and a host of potential defects.

The Problem with Too Much Heat

Pouring metal that is excessively hot is often more dangerous than pouring it too cold. It can lead to several critical defects.

- Gas Porosity: Hotter metal can dissolve more gas (like hydrogen and oxygen). As the metal cools and solidifies, its ability to hold this gas decreases, causing the gas to come out of solution and form bubbles, or porosity, which creates weak spots in the final part.

- Shrinkage Voids: All metals shrink as they cool from a liquid to a solid. A greater temperature difference between the pouring temperature and the solidification temperature results in more total shrinkage, increasing the risk of voids or cracks.

- Mold Degradation: Extreme heat can damage the mold itself. For sand castings, it can cause the binder to break down or the metal to fuse with the sand, resulting in a poor surface finish and dimensional inaccuracies.

The Problem with Too Little Heat

While less common, insufficient temperature presents its own set of immediate failures. The primary issue is a lack of fluidity.

- Misruns and Cold Shuts: A misrun occurs when the metal begins to solidify before it has completely filled the mold cavity. A cold shut is a similar defect where two streams of flowing metal meet but are too cool to fuse together properly, creating a weak seam.

- Poor Surface Detail: If the metal is not fluid enough, it will not flow smoothly against the mold walls, failing to capture fine details and resulting in a rough or incomplete surface.

Making the Right Choice for Your Goal

The ideal pouring temperature is not a single value but depends on the alloy, the mold design, and the desired outcome for the final part.

- If your primary focus is intricate, thin-walled parts: You will need higher superheat to ensure the metal's fluidity allows for complete mold filling before solidification begins.

- If your primary focus is maximizing mechanical strength: Aim for the lowest possible pouring temperature that still ensures mold fill, combined with a controlled cooling method to promote a fine-grain structure.

- If your primary focus is minimizing defects like gas porosity: Use minimal superheat to reduce the amount of gas absorbed by the molten metal and limit total thermal shrinkage.

Ultimately, mastering temperature control is mastering the art and science of casting itself.

Summary Table:

| Temperature Effect | Impact on Casting |

|---|---|

| Too High | Gas porosity, shrinkage voids, mold damage |

| Too Low | Misruns, cold shuts, poor surface detail |

| Optimal | Complete mold fill, controlled grain structure, high part integrity |

Achieve Perfect Castings with KINTEK's Precision Heating Solutions

Mastering the thermal balance is critical to your casting success. KINTEK specializes in high-performance lab furnaces and temperature control equipment, providing the reliability and precision needed to melt, pour, and solidify metals perfectly. Whether you are developing intricate components or prioritizing maximum strength, our solutions help you minimize defects and ensure consistent, high-quality results.

Ready to optimize your casting process? Contact our experts today to find the ideal heating solution for your laboratory's specific alloy and application needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What role does a vacuum hot pressing sintering furnace play in AZ31 densification? Achieve Near-Theoretical Density

- What products are made by hot pressing? Achieve Maximum Density and Performance for Your Components

- What are the critical control factors and monitoring limitations in the HPHT process? Master Stability & Efficiency

- How does the vacuum hot pressing process improve wettability? Unlock Superior Diamond Product Bonding Strength

- How does a vacuum hot press furnace address structural defects in as-cast CoCrPtB alloy ingots? Optimize Your Density