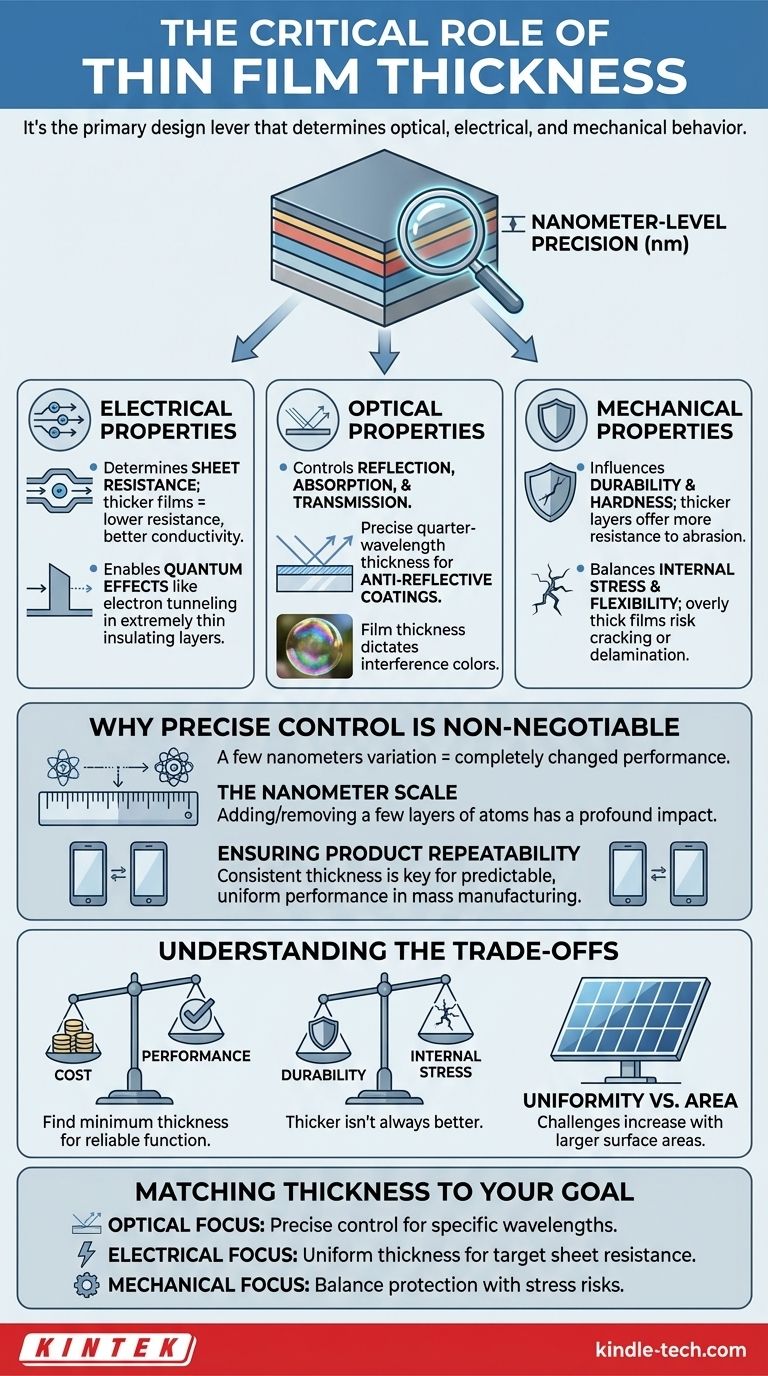

To put it simply, the thickness of a thin film is the single most critical parameter that dictates its physical properties and, therefore, its function. It is not merely a measurement but the primary design lever that determines a film's optical, electrical, and mechanical behavior. Even a variation of a few nanometers can completely change how the material performs in an application.

The core reason thin film thickness is important is that it directly correlates to function. Changing the thickness fundamentally changes how the film interacts with light, electricity, and physical stress, making precise control essential for creating reliable and effective devices.

The Direct Link Between Thickness and Function

A thin film is a layer of material ranging from a few atoms to several micrometers thick. At this microscopic scale, the physical dimension of thickness is not just a passive attribute; it actively governs the material's properties.

Electrical Properties

For conductive films, thickness is directly related to sheet resistance. A thicker film provides a larger cross-sectional area for electrons to flow, resulting in lower resistance and better conductivity.

Conversely, in semiconductor devices, some functions rely on films being extremely thin. A thin insulating layer may be required to allow a quantum mechanical effect known as electron tunneling, which would be impossible if the film were too thick.

Optical Properties

Thickness is paramount for any optical application. It determines how a film reflects, absorbs, and transmits light.

For an anti-reflective coating, the ideal thickness is precisely one-quarter of the wavelength of the light it's designed to counteract. This causes destructive interference, canceling out reflections. Any deviation from this exact thickness degrades performance.

The iridescent colors seen on soap bubbles or oil slicks are also a direct result of thin film interference, where the film's thickness determines which colors are reflected toward your eye.

Mechanical Properties

The thickness of a protective coating determines its durability and hardness. A thicker layer of a hard material like diamond-like carbon (DLC) will offer more resistance to scratches and abrasion.

However, thickness also influences internal stress and flexibility. A very thick film may be more prone to cracking or delamination, while a thinner film will be more flexible and better able to conform to a non-rigid substrate.

Why Precise Control is Non-Negotiable

Because properties are so tightly coupled to thickness, the ability to deposit a film with nanometer-level precision and repeatability is what separates a functional device from a failed one.

The Scale of Nanometers

A nanometer is one-billionth of a meter. At this scale, adding or removing just a few layers of atoms can have a profound impact on the film's overall performance.

This is why deposition processes, such as sputtering, are controlled so carefully. The process is often run at a constant rate for a specific amount of time to achieve the desired thickness down to the angstrom level (one-tenth of a nanometer).

Ensuring Product Repeatability

For any commercial product, from a smartphone screen to a solar panel, every unit must perform identically. Controlling film thickness is the key to ensuring that the optical and electrical properties are consistent across millions of devices.

Without this control, device performance would be unpredictable, rendering mass manufacturing impossible.

Understanding the Trade-offs

Choosing the right film thickness is rarely about maximizing a single property. It almost always involves balancing competing requirements.

Cost vs. Performance

Depositing a thicker film takes more time and consumes more material, which directly increases manufacturing costs. The engineering goal is often to find the minimum thickness that reliably delivers the required performance, optimizing for both function and cost-effectiveness.

Durability vs. Internal Stress

While a thicker protective coating is generally more durable, it also builds up more internal stress during deposition. This stress can cause the film to crack or peel away from the substrate, especially if the substrate flexes or experiences temperature changes.

Uniformity vs. Area

Achieving a perfectly uniform thickness becomes significantly more challenging as the surface area of the substrate increases. A process that works for a small computer chip may not be suitable for coating a large architectural glass panel without introducing unacceptable thickness variations.

Matching Thickness to Your Goal

The "correct" thickness is entirely dependent on the intended application. Your primary objective should guide your material and process decisions.

- If your primary focus is optical performance: Your thickness must be precisely controlled relative to the specific wavelengths of light you need to manage.

- If your primary focus is electrical conductivity: You must deposit a film thick and uniform enough to meet your target for sheet resistance without adding unnecessary cost.

- If your primary focus is mechanical protection: You must balance the need for a durable, thick coating with the risks of internal stress and potential cracking.

Ultimately, thin film thickness is the fundamental variable that translates a material's potential into predictable, real-world performance.

Summary Table:

| Property | How Thickness Affects It | Key Consideration |

|---|---|---|

| Electrical | Determines sheet resistance and enables quantum effects like tunneling. | Critical for semiconductor and conductive film performance. |

| Optical | Controls reflection, absorption, and transmission of light. | Must be precise to the nanometer for anti-reflective coatings. |

| Mechanical | Influences durability, hardness, flexibility, and internal stress. | A balance between protection and risk of cracking/delamination. |

Need precise thin film deposition for your lab's research or product development?

At KINTEK, we specialize in providing high-quality lab equipment, including sputtering systems and deposition tools, that deliver the nanometer-level thickness control essential for reliable optical, electrical, and mechanical performance. Our solutions help researchers and manufacturers achieve consistent, repeatable results, ensuring your devices function as intended.

Contact our experts today to discuss your specific thin film application and find the perfect equipment for your laboratory needs.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Vacuum Cold Mounting Machine for Sample Preparation

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are the advantages and disadvantages of ALD? Precision vs. Speed in Thin Film Deposition

- What are the catalysts for CNT synthesis? The Key to Controlling Carbon Nanotube Growth

- What is atomic layer deposition of a gas? Achieve Perfectly Uniform Thin Films with Atomic Precision

- What are the disadvantages of low pressure CVD? High Costs, Thermal Stress, and Safety Risks

- What is the function of a CVD system in tungsten film fabrication? Precision High-Purity Coating Solutions

- What is sputtering film? A Guide to High-Precision Thin-Film Deposition

- What is the CVD diamond growth process? A Guide to Building Diamonds Atom by Atom

- What is thin-film deposition in vacuum? Unlock Superior Surface Properties