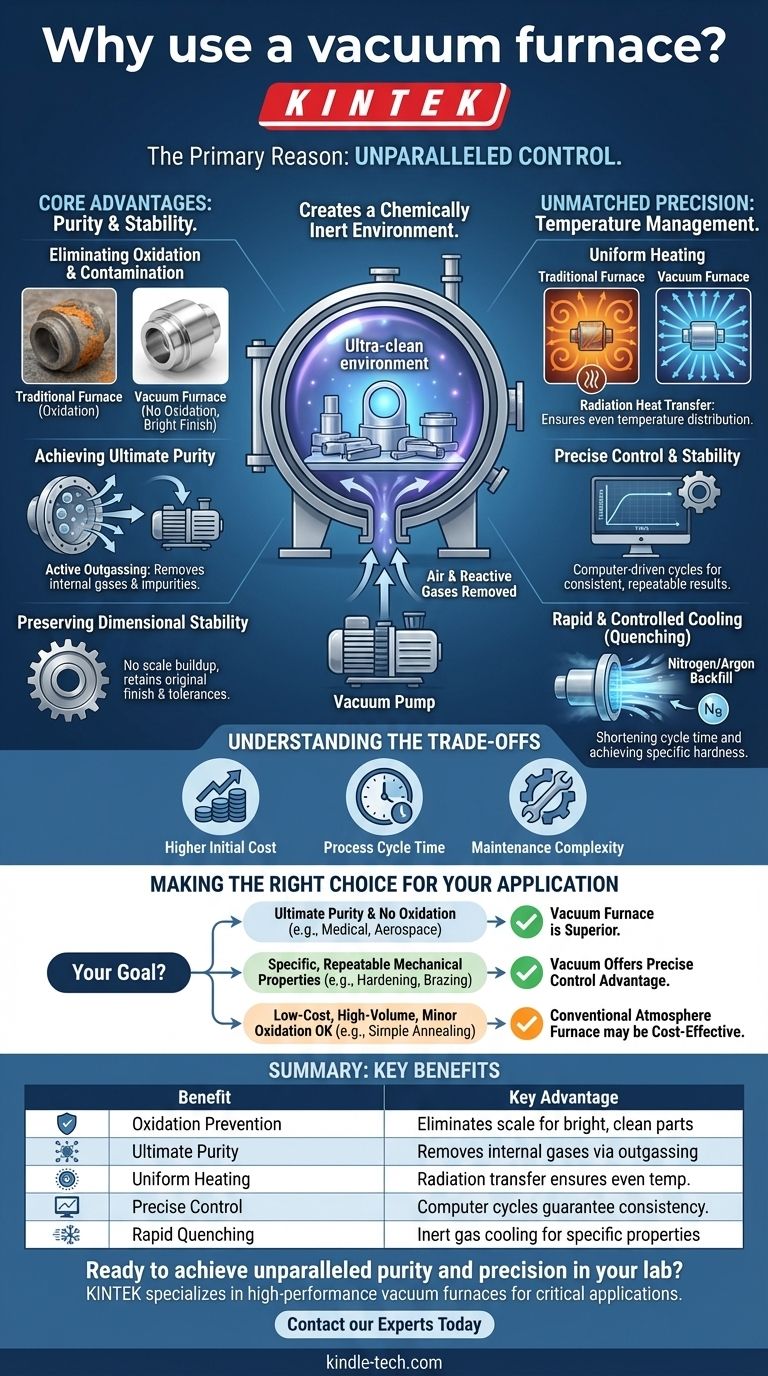

The primary reason to use a vacuum furnace is control. By removing the atmosphere from the heating chamber, you gain unparalleled control over the entire heat treatment process. This creates an ultra-clean environment that prevents oxidation and contamination, allows for extremely uniform temperature management, and enables automated, computer-driven cycles that ensure every part is treated with perfect consistency.

A vacuum furnace is not just a heater; it's a precision instrument. By removing air and other reactive gases, it creates an ultra-clean environment that prevents unwanted chemical reactions like oxidation, leading to finished parts with superior purity, strength, and consistency.

The Core Advantage: A Chemically Inert Environment

The defining feature of a vacuum furnace is the removal of air before heating. This fundamental difference from a traditional atmosphere furnace is the source of its most significant benefits.

Eliminating Oxidation and Contamination

At high temperatures, materials react aggressively with the oxygen in the air, forming a brittle, discolored layer of scale or oxide. A vacuum furnace physically removes the oxygen, completely preventing oxidation.

This process also eliminates other reactive gases and impurities. The result is a bright, clean part that requires no subsequent cleaning to remove scale.

Achieving Ultimate Purity

The vacuum environment doesn't just prevent contaminants from getting in; it actively pulls them out.

During heating, materials can "outgas," releasing trapped internal gases or byproducts from prior manufacturing steps. A vacuum pumping system continuously removes these byproducts, resulting in a finished component with higher purity.

Preserving Dimensional Stability

Because there is no scale buildup or surface reaction, parts treated in a vacuum retain their original surface finish and dimensions with exceptional accuracy. This is critical for complex, high-tolerance components.

Unmatched Precision in Temperature Management

Control over the environment extends directly to control over the temperature. The absence of air fundamentally changes how heat is transferred, allowing for a much higher degree of precision.

Uniform Heating

In a vacuum, heat is transferred primarily through radiation, not convection (air currents). This allows for highly uniform temperature distribution across the entire heating zone, ensuring that large or complex parts are heated evenly.

This uniformity is key to preventing warping and ensuring consistent metallurgical properties throughout the component.

Precise Control and Stability

Modern vacuum furnaces use advanced computer control systems to manage the process. These systems can execute pre-programmed heating and cooling cycles with incredible precision, ensuring excellent temperature stability for consistent and repeatable results.

Rapid and Controlled Cooling (Quenching)

After heating, parts often need to be cooled rapidly—a process called quenching—to achieve desired hardness. Vacuum furnaces accomplish this by backfilling the chamber with a high-pressure, inert gas like nitrogen or argon.

This method allows for very rapid and controlled cooling, shortening the overall process time while achieving specific metallurgical properties.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heat-treating needs. Objectivity requires acknowledging its limitations.

Higher Initial Cost

Vacuum furnaces represent a significant capital investment. The complex systems for creating and maintaining a vacuum, including pumps and seals, make them more expensive than most traditional atmosphere furnaces.

Process Cycle Time

The time required to pump the chamber down to the target vacuum level can add to the overall cycle time. While the quenching phase can be very fast, the initial pump-down phase must be factored in.

Maintenance Complexity

The high-tech components of a vacuum furnace, particularly the vacuum pumps and chamber seals, require specialized and diligent maintenance to ensure optimal performance and prevent leaks.

Making the Right Choice for Your Application

The decision to use a vacuum furnace should be driven by the specific requirements of your material and final product.

- If your primary focus is ultimate material purity and preventing any surface oxidation (e.g., medical implants, aerospace components): A vacuum furnace is the superior and often necessary choice.

- If your primary focus is achieving specific, repeatable mechanical properties (e.g., hardening tool steels, brazing complex assemblies): The precise process control of a vacuum furnace offers a significant advantage over other methods.

- If your primary focus is low-cost, high-volume heat treatment where minor surface oxidation is acceptable (e.g., simple annealing of non-critical parts): A conventional atmosphere furnace may be a more cost-effective solution.

Ultimately, choosing a vacuum furnace is an investment in process control that guarantees the highest level of material quality and consistency.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Oxidation Prevention | Eliminates scale and contamination for bright, clean parts |

| Ultimate Purity | Removes internal gases and impurities through outgassing |

| Uniform Heating | Radiation-based heat transfer ensures even temperature distribution |

| Precise Control | Computer-driven cycles guarantee consistent, repeatable results |

| Rapid Quenching | High-pressure inert gas cooling for specific metallurgical properties |

Ready to achieve unparalleled purity and precision in your lab?

KINTEK specializes in high-performance vacuum furnaces designed for critical applications in aerospace, medical, and advanced materials. Our solutions deliver the ultimate control to prevent oxidation, ensure uniform heating, and guarantee consistent results for your most demanding projects.

Contact our experts today to discuss how a KINTEK vacuum furnace can enhance your laboratory's capabilities and product quality.

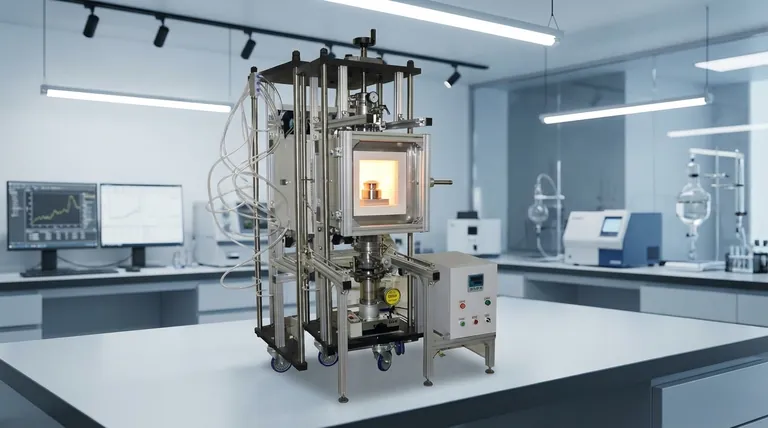

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory High Pressure Vacuum Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- How does the co-sintering process improve bulk-type ASSBs? Optimize Interfaces with Advanced High-Temperature Furnaces

- What are the major products from biomass pyrolysis? Tune Your Process for Biochar, Bio-oil, or Gas

- What features are required in high-temperature furnace equipment for the large-scale pyrolysis of nano-packaging particles?

- Why is a high-precision tempering furnace required for PM-HIP joints? Ensure Toughness in SA508 Steel

- Why are high-precision furnaces required for alkali glass electrolytes? Optimize Melt-Quenching Stability

- Does hardening increase strength? Unlock the Key to Superior Material Performance

- Why is vacuum heat treatment necessary after coating solid electrolyte? Ensure Accurate Ionic Conductivity Results