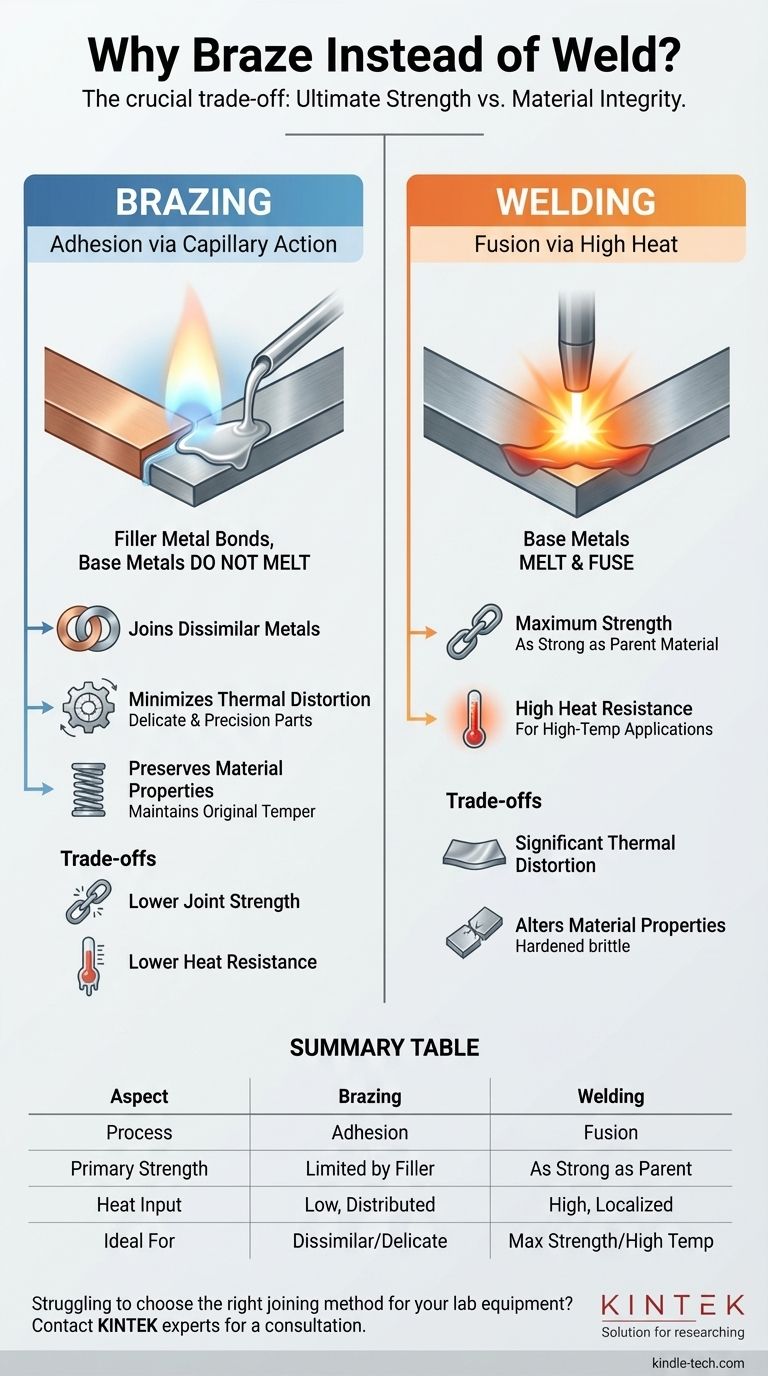

The choice between brazing and welding hinges on a crucial trade-off between ultimate strength and material integrity. You braze instead of weld when your priority is joining dissimilar metals, minimizing heat distortion on delicate parts, or preserving the base metals' original properties. While a welded joint is fundamentally stronger and more heat-resistant, brazing is a superior choice when the high heat of welding would compromise the entire assembly.

The core difference is simple: welding melts the base metals to fuse them together, while brazing uses a lower-temperature filler metal to bond them like a metallic glue. Your decision depends on whether the integrity of the original materials is more critical than the absolute strength of the joint itself.

The Fundamental Difference: Heat and Fusion

Understanding when to use each process starts with understanding how they work at a metallurgical level. They are not interchangeable; they are fundamentally different joining philosophies.

How Welding Works: A Fusion Process

Welding is a high-temperature fusion process. It uses an intense, focused heat source (like an electric arc or a flame) to melt the edges of the base materials.

A filler metal is often added to the molten pool. This mixture of melted base metal and filler metal then cools and solidifies, creating a single, continuous piece of metal.

This fusion is why welding provides superior strength and heat resistance. The joint becomes an integral part of the parent materials.

How Brazing Works: A Capillary Action Process

Brazing is a lower-temperature adhesion process. The base metals are heated, but crucially, they are never melted.

Instead, a filler metal with a lower melting point is introduced to the joint. This molten filler is drawn between the closely fitted surfaces of the parent materials by a phenomenon called capillary action.

The filler metal then solidifies, forming a strong, permanent bond that holds the base metals together without altering their core structure.

Key Advantages of Brazing

The lower heat and non-fusion nature of brazing create several distinct advantages that make it the ideal choice for specific applications.

Joining Dissimilar Metals

Because the base metals don't melt and mix, their metallurgical compatibility is far less of an issue. Brazing makes it simple to join fundamentally different materials, such as copper to steel or aluminum to brass, which can be difficult or impossible with conventional welding.

Minimizing Thermal Distortion

The significant and localized heat of welding causes materials to expand and contract rapidly, often resulting in warping and distortion. Brazing uses significantly less heat, which is applied more broadly, drastically reducing the risk of distortion. This is critical for maintaining tight tolerances on complex or delicate assemblies.

Preserving Material Properties

The intense heat of welding can alter the carefully engineered properties of the base metals, such as hardness from heat-treating or temper from work-hardening. Brazing's lower temperatures operate below the critical transformation points of most metals, leaving their metallurgical characteristics intact.

Understanding the Trade-offs

Choosing brazing means accepting a clear set of compromises in exchange for its unique benefits. Objectivity here is critical.

Strength is the Primary Compromise

A brazed joint's strength is limited by the strength of the filler metal. While a properly designed brazed joint is exceptionally strong, it cannot match the strength of a welded joint, where the bond is as strong as the parent material itself.

Lower Heat Resistance

This is a direct consequence of the process. The filler metal used in brazing has a lower melting point than the base metals. Therefore, a brazed assembly cannot be used in high-temperature applications where service temperatures might approach the filler's melting point.

Requires Cleaner Surfaces and Tighter Fits

Brazing relies on capillary action, which only works if the surfaces are extremely clean and the gap between parts is small and consistent. Welding is generally more forgiving of small imperfections in surface preparation and fit-up.

Making the Right Choice for Your Application

The best method is the one that meets the specific engineering demands of your project without creating unintended consequences.

- If your primary focus is maximum strength and high-temperature performance: Welding is the superior choice, as the fusion of base metals creates the most robust and heat-resistant bond.

- If your primary focus is joining dissimilar metals or delicate components: Brazing provides the control and low-heat input necessary to join incompatible materials without damaging or distorting them.

- If your primary focus is maintaining tight tolerances and preserving material temper: Brazing's gentle heating and lack of fusion make it the only viable option for heat-sensitive and high-precision assemblies.

Ultimately, choosing the right joining method requires you to look beyond the joint itself and consider the integrity of the entire finished part.

Summary Table:

| Aspect | Brazing | Welding |

|---|---|---|

| Process | Lower-temperature adhesion (filler metal bonds) | High-temperature fusion (base metals melt) |

| Primary Strength | Limited by filler metal strength | As strong as the parent material |

| Heat Input | Low, distributed heat | High, localized heat |

| Ideal For | Dissimilar metals, delicate parts, preserving temper | Maximum strength, high-temperature applications |

Struggling to choose the right joining method for your lab equipment or delicate components?

At KINTEK, we specialize in providing solutions for complex laboratory needs. Our expertise in material joining ensures your assemblies maintain their integrity and precision. Whether you're working with dissimilar metals or heat-sensitive components, we can help you select the optimal process.

Let's discuss your project and ensure a perfect bond. Contact our experts today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- How does high-temperature heating equipment simulate the service environment of ceramics? Expert Testing Strategies

- What materials are used in vacuum braze? A Guide to Metals, Alloys, and Filler Selection

- How does the degassing step in a vacuum oven influence the quality of molded F-LSR components? Enhance Material Strength

- What are the main components of a hot zone used in a high-temperature furnace? Ensure Optimal Performance and Efficiency

- What is classification of heating furnace? A Guide to Selecting the Right Industrial Furnace

- What is the role of a vacuum oven during the dehydration phase of molten salt electrolysis? Ensure Process Stability

- What is the difference between sintering and smelting? Consolidation vs. Extraction Explained

- What is the use of a heat treatment furnace? Transform Material Properties for Superior Performance