Handheld XRF Analyzers

In-Line XRF Analzyer

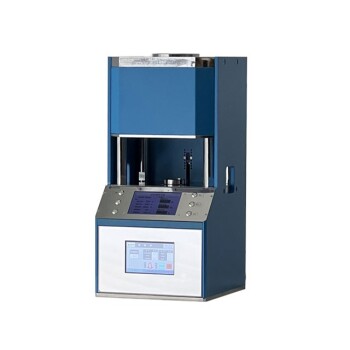

Item Number : XRF-700

Price varies based on specs and customizations

- Detector

- High performance SDD detector

- Power Supply

- 9 VAC power adapter

- Analysis Mode

- Alloy or Coating

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Introduction

In metal material analysis and grade identification, manually operated handheld XRF analysis is an efficient testing method. However, when there is a large number of products that need to be inspected or downstream customers require complete inspection of products, in the face of huge amount of inspection tasks, handheld XRF analyzers using manual inspection can no longer meet the requirement of the factory. Therefore, We launched the In-line 700 of online XRF analyzers, which can well meet the needs of users for online real-time detection of large-scale products. The chemical element composition information and the screening of faulty products have greatly improved the detection efficiency and reduced labor costs.

Applications

The Scientific In-line XRF analyzer XRF700 series is a versatile and efficient tool designed for real-time inspection and quality control in various industrial settings. This analyzer, equipped with advanced electronics and sophisticated mathematical algorithms, offers rapid, accurate, and non-destructive analysis, making it ideal for a range of applications in metal processing and quality assurance. Here are the main application areas of the In-Line XRF Analyzer:

- Metal Scraps Sorting: Efficiently sorts and categorizes different types of metal scraps based on their elemental composition, aiding in recycling processes.

- Factory Incoming Metal Material Inspection: Ensures that incoming materials meet specified standards by quickly analyzing their elemental composition.

- Production Quality Control (QC/QA): Monitors and controls the quality of products during the manufacturing process, ensuring compliance with quality standards.

- Quick Identification of Alloy Grades: Rapidly identifies the grade of alloys used in various applications, facilitating proper usage and processing.

- Rapid Identification and Sorting of Scrap Metal: Helps in the quick and accurate sorting of scrap metal, optimizing recycling operations and reducing waste.

- FAC Inspection: Performs Field Activated Chemistry (FAC) inspections to ensure the integrity and quality of materials in various industrial applications.

- Car Catalyst Converter Analysis: Analyzes the composition of catalyst converters in vehicles, ensuring they meet environmental and performance standards.

These applications highlight the In-Line XRF Analyzer's capability to enhance efficiency and accuracy in various industrial processes, contributing to better quality control and resource management.

Detail&Parts

Features

The XRF Scientific In-line XRF analyzer XRF700 series is a cutting-edge solution designed for real-time inspection and quality control in industrial production lines. This system is particularly beneficial for industries requiring high precision and efficiency in their quality assurance processes. Here are the key features that highlight its advantages:

- Flexible Configuration: The XRF700 series can be customized to fit various factory layouts and production scenarios, ensuring seamless integration into existing workflows.

- Integration with Robotic Arms and Automation: This feature allows for a high degree of automation, reducing the need for human intervention and enhancing the speed and accuracy of the inspection process.

- Efficient Detection Solution: By adapting to the characteristics of different samples, the analyzer provides a tailored approach to quality control, optimizing the detection process for various materials.

- Real-Time Inspection and Quality Control: The system operates around the clock, providing continuous monitoring and ensuring that any issues are detected immediately, thus minimizing downtime and waste.

- Automation of the Detection Process: With minimal human intervention required, the system reduces the potential for human error, leading to more reliable and consistent results.

These features collectively enhance the efficiency, accuracy, and reliability of quality control processes in industrial settings, making the XRF Scientific In-line XRF analyzer XRF700 series a valuable asset for modern manufacturing environments.

Principle

The In-Line XRF Analyzer uses X-ray Fluorescence (XRF) to analyze elemental composition. It bombards samples with X-rays, causing inner electrons to eject and emit characteristic photons, identifying elements in real-time for continuous quality control.

Advantage

- Flexible Configuration and Integration: The XRF Scientific In-line XRF analyzer XRF700 series can be flexibly configured and effectively integrated with robotic arms and automatic devices, adapting to the specific layout and requirements of factory production lines. This integration forms an efficient detection solution tailored to the characteristics of different samples, enhancing overall production efficiency and quality control.

- Automation and Minimal Human Intervention: The entire detection process is automated, reducing the need for human intervention and minimizing the potential for human error. This automation ensures consistent and reliable results, optimizing the workflow and reducing labor costs.

- Real-Time Inspection and Quality Control: The online inspection solution provides real-time monitoring and quality control of production line products around the clock. This continuous monitoring ensures that any issues or deviations in product quality are detected immediately, allowing for timely corrective actions and maintaining high standards of product quality.

- Non-Destructive Testing: Utilizing X-ray fluorescence (XRF), the analyzer performs non-destructive testing, preserving the integrity of the samples. Unlike destructive methods like acid and fire assay, the samples remain intact, which is crucial for materials that cannot be compromised or for further testing and analysis.

- Reliably Accurate and Precise: The analyzer achieves results comparable to fire assay, helping to prevent losses from under-karated or counterfeit materials. This high level of accuracy and precision is essential for industries dealing with precious metals and other valuable materials, ensuring that the materials meet the required standards and specifications.

- Detection of Gold Plating: The system is efficient in identifying gold-plated items, including gold-plated silver, gold-plated copper, steel, tungsten, and other non-gold substrates. This capability is crucial for distinguishing genuine gold from plated materials, which is important in industries dealing with precious metals to avoid fraud and ensure product authenticity.

- Designed for Practicality: Tailored for retail environments, the XRF analyzer is factory-calibrated and ready for use upon arrival. The closed-beam design ensures no x-ray exposure to customers or operators, enhancing safety and ease of use in various settings.

Specification

| Excitation Source | X-ray tube:Rhodium or tungsten anode target (optimized for application), 5 to 200 μA, 8 to 50keV (4 W max) |

| Detector | High performance SDD detector |

| Power Supply | 9 VAC power adapter |

| Analysis Mode | Alloy or Coating |

| Analysis range | Elements from Potassium (K19) to Uranium (U92) |

| IP Rating | IP54 |

| Temperature Range | 10C to 50C. continuous operation |

| Humidity | 10 % to 90 % relative humidity, non-condensing |

| Operating System | Linux |

| Software | Proprietary data acquisition and processing software package |

FAQ

What Is A Handheld XRF Analyzer?

What Is The XRF Scientific In-line XRF Analyzer XRF700 Series Used For?

How Does The In-line XRF Analyzer Integrate With Factory Production Lines?

What Are The Benefits Of Using The In-line XRF Analyzer?

Can The In-line XRF Analyzer Handle Different Types Of Samples?

What Are The Main Applications Of Handheld XRF Analyzers?

How Does A Handheld XRF Analyzer Work?

What Are The Advantages Of Using A Handheld XRF Analyzer?

Can Handheld XRF Analyzers Be Used For All Elements?

How Fast Can A Handheld XRF Analyzer Provide Results?

Are Handheld XRF Analyzers Suitable For Environmental Monitoring?

Do Handheld XRF Analyzers Require Extensive Training To Use?

4.8

out of

5

Fast delivery and easy integration for increased efficiency.

4.7

out of

5

Cost-effective solution for real-time 100% quality control.

4.9

out of

5

Rugged and durable design suitable for various working environments.

4.8

out of

5

Efficient real-time analysis and display of element content.

4.7

out of

5

Easy to install on the production line, saves time and labor costs.

4.9

out of

5

Low maintenance cost and quick recovery of investment.

4.8

out of

5

Unique design for effortless integration, great for factory use.

4.7

out of

5

Fast analysis results in seconds, saving valuable time.

4.9

out of

5

Reliable and accurate alloy grade identification.

4.8

out of

5

Remote real-time monitoring for efficient data management.

4.7

out of

5

Significant reduction in manual inspection costs, highly efficient.

4.9

out of

5

Real-time 100% quality control for processed products.

4.8

out of

5

Efficient pass/fail results and material composition info displaying.

4.9

out of

5

Advanced SDD detector for quick determination of product quality.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

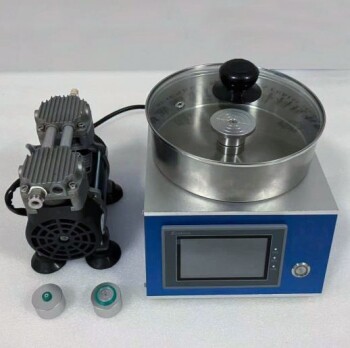

Scientific In-line XRF Spectrometer Module series can be flexibly configured, and can be effectively integrated with robotic arms and automatic devices according to the layout and actual situation of the factory production line to form an efficient detection solution that meets the characteristics of different samples.

XRF600 Handheld Soil Analyzer is an important tool for soil and sediment screening. It can detect hazardous heavy metals within seconds. Using XRF600 for on-site rapid soil screening significantly reduces the number of samples that need to send to laboratory for analysis, reducing analysis costs and analysis time. And soil treatment and remediation costs can be minimized by rapidly screening and delineating contaminated areas and identifying remediation areas on-site.

XRF600M, a fast, accurate, and easy-to-use handheld XRF mining analyzer designed for different analytical applications in the mining industry. The XRF600M provides on-site analysis of ore samples with minimal sample preparation, reducing the time for lab assay from days to minutes. With the fundamental parameters method, the XRF60M is capable of analyzing an ore sample without the need for any calibration standards.

XRF 200 Benchtop Gold analyzer offers a rapid and remarkably precise method for assessing karat or gold content, serving quality control, pricing, and practical utilization needs.

4 inch acrylic cavity fully automatic laboratory homogenizer

The 4-inch acrylic cavity fully automatic laboratory glue dispensing machine is a compact, corrosion-resistant, and easy-to-use machine designed for use in glove box operations. It features a transparent cover with constant torque positioning for chain positioning, an integrated mold opening inner cavity, and an LCD text display color facial mask button. The speed of acceleration and deceleration is controllable and adjustable, and multi-step program operation control can be set.

XRF900 are good choice for metal analysis in many fileds, delivering rapid, accurate results right in your hand.

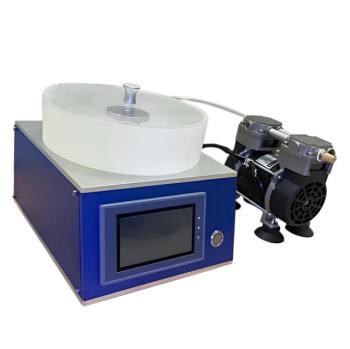

4 inch aluminum alloy chamber fully automatic laboratory glue homogenizer

The 4-inch aluminum alloy cavity fully automatic laboratory glue dispensing machine is a compact and corrosion-resistant device designed for laboratory use. It features a transparent cover with constant torque positioning, an integrated mold opening inner cavity for easy disassembly and cleaning, and an LCD text display color facial mask button for ease of use.

Handheld Precious Metal Analyzer

XRF990 handheld precious metal analyzer, based on advanced ceramic packaged microfocus X-ray tube and high-performance semiconductor detector, combined with advanced software algorithm, can quickly, accurately and non-destructively test gold, silver, platinum and other precious metals concentration in jewelry, to fast indentify the purity of jewelry, investment gold and various precious metal materials.

Handheld Lithium Battery Analyzer

XRF970 handheld lithium battery analyzer, based on advanced ceramic packaged microfocus X-ray tube and high-performance semiconductor detector, combined with advanced software algorithms, can quickly and accurately analyzer Ni, Co, Mn and other regulated elements in lithium batteries. It is an ideal portable analyzer for lithium battery manufacturers’ process quality control and safety precautions, and for waste lithium battery recyclers’ sorting tasks.

XRD sample holder / X-ray diffractometer powder slide

X-ray powder diffraction (XRD) is a rapid technique for identifying crystalline materials and determining their unit cell dimensions.

12 inch/24 inch high precision automatic diamond wire cutting machine

The high precision automatic diamond wire cutting machine is a versatile cutting tool that uses a diamond wire to cut through a wide range of materials, including conductive and non-conductive materials, ceramics, glass, rocks, gems, jade, meteorites, monocrystalline silicon, silicon carbide, polycrystalline silicon, refractory bricks, epoxy boards, and ferrite bodies. It is especially suitable for cutting various brittle crystals with high hardness, high value, and easy to break.

The handheld XRF coating thickness analyzer adopts high-resolution Si-PIN (or SDD silicon drift detector) achieve an excellent measurement accuracy and stability. Whether it is for the quality control of coating thickness in the production process, or random quality check and complete inspection for incoming material inspection, XRF-980 can meet your inspection needs.

Manual hydraulic presses are mainly used in laboratories for various applications such as forging, molding, stamping, riveting and other operations. It allows the creation of complex shapes while saving material.

XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

Produce perfect XRF samples with our steel ring lab powder pellet pressing mold. Fast tableting speed and customizable sizes for accurate molding every time.

Automatic heated hydraulic lab press laboratory hot press

The Automatic High Temperature Heat Press is a sophisticated hydraulic hot press designed for efficient temperature control and product quality processing.

XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

Get precise XRF samples with our plastic ring lab powder pellet pressing mold. Fast tableting speed and customizable sizes for perfect molding every time.

High precision diamond wire cutting machine

The high precision diamond wire cutting machine is a versatile and precise cutting tool designed specifically for material researchers. It utilizes a continuous diamond wire cutting mechanism, enabling precise cutting of brittle materials such as ceramics, crystals, glass, metals, rocks, and various other materials.

4 inch stainless steel chamber fully automatic laboratory glue homogenizer

The 4-inch stainless steel chamber fully automatic laboratory glue homogenizer is a compact and corrosion-resistant device designed for use in glove box operations. It features a transparent cover with constant torque positioning and an integrated mold opening inner cavity for easy disassembly, cleaning, and replacement.

Manual heated hydraulic lab press laboratory hot press

The Manual Heat Press is a versatile piece of equipment suitable for a variety of applications, operated by a manual hydraulic system that applies controlled pressure and heat to the material placed on the piston.

4 inch PTFE cavity fully automatic laboratory homogenizer

4 inch PTFE cavity fully automatic laboratory homogenizer is a versatile laboratory equipment designed for efficient and precise homogenization of small samples. It features a compact design, allowing for easy glove box operation and space optimization.

4 inch PP chamber fully automatic laboratory homogenizer

Compact and efficient glue homogenizer for precise sample preparation in laboratories, featuring a 4-inch PP chamber, corrosion-resistant design, user-friendly LCD display, and customizable speed settings for optimal homogenization results.

XRF Boric Acid lab Powder Pellet Pressing Mold

Get accurate results with our XRF Boric Acid lab Powder Pellet Pressing Mold. Perfect for preparing samples for X-ray fluorescence spectrometry. Custom sizes available.

Related Articles

Comprehensive Guide to XRF Spectrometer Modules: Integration, Applications, and Analysis Techniques

Explore the versatility and operational details of XRF Spectrometer Modules, including integration with automation, types of XRF spectrometers, and their applications in various industries. Learn how these modules enhance real-time inspection and quality control in production lines.

Comprehensive Guide to the XRF 200 Benchtop Gold Analyzer: Features, Benefits, and Applications

Discover the XRF 200 Benchtop Gold Analyzer, a rapid and precise tool for assessing gold content and alloy composition. Ideal for quality control and pricing in various settings.

Unlocking the Power of XRF Spectrometer Modules: A Comprehensive Guide

Explore the intricacies of XRF spectrometer modules, from basic components to advanced applications. Learn how these devices enhance elemental analysis in various industries.

Comprehensive Guide to the XRF Benchtop Gold Analyzer: Features, Benefits, and Applications

Explore the XRF 200 Benchtop Gold Analyzer, a cutting-edge tool for precise gold content assessment. Learn about its features, applications in quality control, and benefits for the gold industry.

A Comprehensive Guide to Handheld XRF Analyzers: Technology, Applications, and Benefits

Unlock the potential of handheld XRF analyzers with this comprehensive guide. Learn about the technology, applications, and advantages of these devices. From mining exploration to metal material analysis, understand how these analyzers provide fast, accurate, and non-destructive results.

Revolutionizing Quality Control: The Ultimate Guide to Handheld Alloy Analyzers

Explore the advanced features and benefits of handheld alloy analyzers, including fast analysis, real-time data management, and cost-effective solutions for industrial quality control. Discover how these devices can enhance your production processes and ensure 100% quality assurance.

Comprehensive Guide to Handheld Precious Metal Analyzers: Features, Applications, and Benefits

Explore the advanced capabilities of handheld precious metal analyzers like XRF 990 and XRF 200, their applications in jewelry testing, recycling, and quality control, and how they offer fast, accurate, and non-destructive analysis of precious metals.

Comprehensive Guide to Handheld Soil Analyzers: Revolutionizing Soil Testing and Remediation

Explore the capabilities of Handheld Soil Analyzers like AXR600, which offer rapid detection of heavy metals and reduce soil testing costs. Ideal for environmental monitoring and remediation.

Unlocking Purity: The Ultimate Guide to Handheld Precious Metal Analyzers

Discover the power of XRF990 handheld precious metal analyzer in accurately testing gold, silver, platinum purity. Ideal for jewelers, recyclers, and quality inspectors.

Ultimate Guide to Handheld Alloy Analyzers: Features, Applications, and Advantages

Explore the world of handheld alloy analyzers, their applications in various industries, and the benefits they offer. Discover how these devices provide rapid, accurate, and non-destructive analysis for quality control and material verification.

Comprehensive Guide to Handheld XRF Analyzers: Applications, Best Practices, and Selection Tips

Explore the versatile applications, best practices, and selection criteria for handheld XRF analyzers. Learn how these portable devices enhance efficiency and accuracy in various industries.

Handheld Coating Thickness Gauges: Accurate Measurement for Electroplating and Industrial Coatings

Discover the best practices and technologies for measuring coating thickness using handheld gauges. Ideal for electroplating, automotive paint, and powder coatings.