Introduction to Electrolytic Cells

Electrolytic cells are chemical cells that use electricity to generate a non-spontaneous redox reaction. These cells are used in various electrochemical processes such as electrolysis and electroplating. Electrolysis is the process of using electrical energy to drive a chemical reaction that would not occur spontaneously. Electrolytes are used as the conducting medium for the flow of electrical current between the cathode and anode. The components of an electrolytic cell include electrodes, an electrolyte, and a power source. Electrolytic cells find applications in various fields ranging from metallurgy to medicine.

Table of Contents

- Introduction to Electrolytic Cells

- Definition of Electrolysis and Electrolyte

- Components of an Electrolytic Cell

- How Electrolytic Cells Work

- Applications of Electrolytic Cells

- Purification of Copper through Electrolysis

- Electroplating using Electrolytic Cells

- Other Applications of Electrolytic Cells

Definition of Electrolysis and Electrolyte

Electrolytic cells are devices that use electricity to drive chemical reactions. Electrolysis is a type of process where an electric current is passed through a liquid or a solution containing ions, which causes the substances inside to decompose. In this process, we use a direct current power source, meaning that the electrodes are always either positive or negative. A substance or mixture that conducts electricity and can undergo electrolysis is called an electrolyte.

What is Electrolysis?

Electrolysis is the process of using an electric current to drive a chemical reaction that separates the components of a compound. The two main components of the electrolytic cell are the anode and the cathode. The anode is the positive electrode, while the cathode is the negative electrode. When an electric current is passed through the electrolyte, the anions and cations move towards the respective electrodes. The anions move towards the anode while the cations move towards the cathode.

What is an Electrolyte?

An electrolyte is a type of substance or mixture that contains mobile ions that can undergo electrolysis. To sustain an electrolytic reaction, we need to have a complete circuit, which means we need to continuously get power from the battery or power supply. To do this, we need our ions to be able to move. Therefore, the electrolyte must be either a salt solution or a molten salt.

The choice of electrolyte depends on the specific application and the type of metal being purified or plated. Common electrolytes include sulfuric acid, sodium hydroxide, and various salts. The electrolyte plays a critical role in the electrolytic cell, as it contains the ions that will be reduced or oxidized during the electrolysis process.

In summary, electrolysis is the process of using an electric current to drive a chemical reaction that separates the components of a compound. An electrolyte is a substance or mixture that contains mobile ions that can undergo electrolysis. The choice of electrolyte depends on the specific application and the type of metal being purified or plated. The electrolyte plays a critical role in the electrolytic cell, as it contains the ions that will be reduced or oxidized during the electrolysis process.

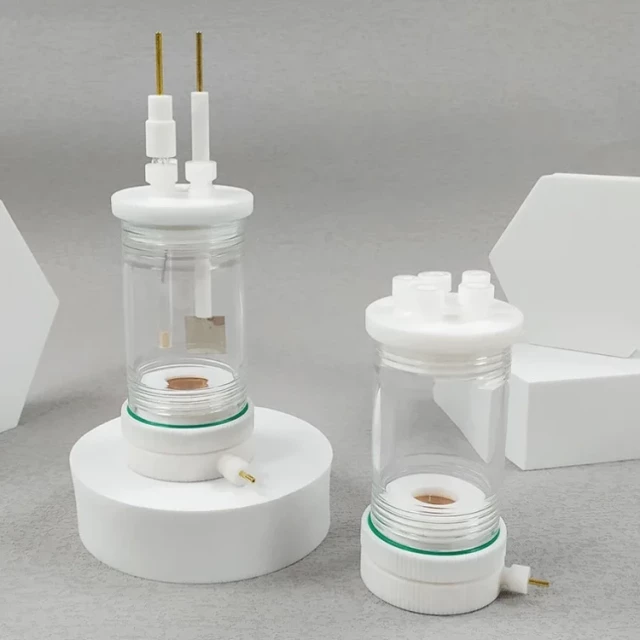

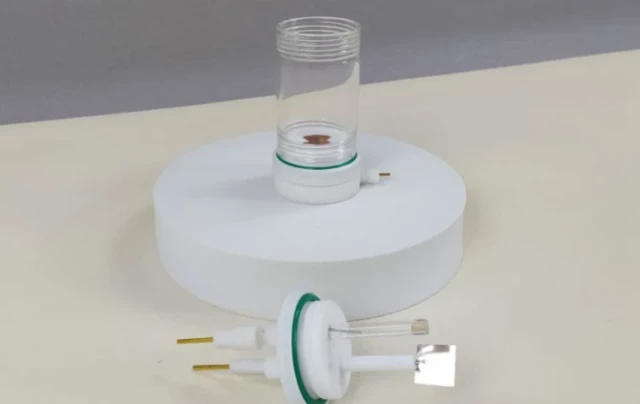

Components of an Electrolytic Cell

Electrolytic cells are electrochemical cells used for the electrolysis of compounds and have numerous applications in various industries. The main components of an electrolytic cell include the anode, cathode, electrolyte, electrical source, and a mechanism to control the flow of current.

Anode and Cathode

The anode is the electrode where oxidation occurs, and it is positively charged. The cathode is the electrode where reduction occurs, and it is negatively charged. During the electrolysis process, the anode attracts negatively charged ions, while the cathode attracts positively charged ions.

Electrolyte

The electrolyte is the solution that contains the metal ions to be purified or plated. Commonly used electrolytes in electrolytic cells include water (containing dissolved ions) and molten sodium chloride. The solution should have metal ions that can be reduced at the cathode and impurities that can be oxidized at the anode.

Electrical Source

The electrical source provides the energy for the process to occur. A direct current (DC) must be used since the process requires the flow of electrons in one direction only. A battery or a DC power supply can be used as an electrical source.

Mechanism to Control the Flow of Current

The mechanism to control the flow of current ensures that the process occurs at the desired rate. A resistor can be used to limit the flow of current, and a potentiometer can be used to adjust the voltage. The use of a voltmeter and an ammeter allows the measurement of the voltage and current, respectively.

Salt Bridge

In some cases, a salt bridge may be required to complete the circuit. A salt bridge is a tube filled with an electrolyte solution that connects the two half-cells. The salt bridge maintains electrical neutrality and allows the flow of ions between the two half-cells.

In conclusion, the components of an electrolytic cell are crucial in the process of electrolysis. The anode, cathode, electrolyte, electrical source, and mechanism to control the flow of current work together to ensure the successful purification or electroplating of metals. Understanding the components and their functions can help in the proper design and use of electrolytic cells for various industrial applications.

How Electrolytic Cells Work

Electrolytic cells are devices used to carry out electrolysis, a process that involves the use of an electric current to drive a non-spontaneous chemical reaction. The process of electrolysis is based on the principles of electrochemistry, which involves the movement of charged particles (ions) in an electric field. This movement of ions is facilitated by the presence of an electrolyte solution that contains ions that can conduct electricity.

Components of an Electrolytic Cell

An electrolytic cell has three main components: an electrolyte solution and two electrodes - a cathode and an anode. The electrolyte solution is typically a dissolved ion solution in water or other solvents, and the electrodes are made of materials that can conduct electricity and also react with the ions in the electrolyte.

Working of an Electrolytic Cell

When a direct current is applied to an electrolytic cell, electrons flow from the anode to the cathode, while ions flow from the electrolyte to the electrodes. At the anode, metal ions are oxidized and dissolve in the electrolyte solution. The resulting electrons are released into the external circuit. At the cathode, metal ions are reduced and deposited on the surface. This results in a pure metal product that can be used for various applications.

Electroplating

Electrolytic cells are also used in electroplating to deposit a thin layer of one metal onto the surface of another metal. The metal to be plated is made the cathode and the metal to be deposited is made the anode. When a direct current is applied, metal ions from the anode are oxidized and dissolve in the electrolyte solution, while metal ions at the cathode are reduced and deposited on the surface. This results in a metal coating that can be used for various applications, such as improving the appearance or corrosion resistance of a metal object.

Conclusion

In conclusion, electrolytic cells play a critical role in various applications, including purification and electroplating. The movement of ions in an electric field is facilitated by the presence of an electrolyte solution that contains ions that can conduct electricity. The resulting chemical reactions at the electrodes lead to the desired products. Electrolytic cells have various applications in industry and research, and their use is critical for the production of metals and other materials that are essential for modern society.

Applications of Electrolytic Cells

Electrolytic cells are commonly used in various industries for their ability to drive chemical reactions through electrolysis. In this process, electrical energy is used to break down a chemical substance into its component parts. This allows for the purification of metals and the creation of thin metal coatings on conductive surfaces, among other applications.

Electroplating

One of the most common applications of electrolytic cells is electroplating. This process involves the deposition of a thin layer of metal onto a conductive surface using an electrical current. Electroplating is used in many industries to improve the appearance of objects, increase their resistance to corrosion, and provide wear resistance. This process is also commonly used in jewelry making and other aesthetic applications.

Purification of Metals

Electrolytic cells are also used in the purification of metals obtained through mining or other industrial processes. Impure metals are dissolved in a solution and passed through an electrolytic cell. The process causes the impurities to be selectively removed from the solution, leaving behind a more pure metal. This is an economical and straightforward process for purification of non-ferrous metals.

Electrowinning or Electro-Refining

Electrowinning and electro-refining are electroplating applications used to produce various pure metals such as sodium, calcium, aluminum, and magnesium. The processes are used to purify metals by removing impurities, making them an essential tool in many industries. In electrowinning, a metal is kept in a liquid leach solution, and then a current is passed from an inert anode to the leach solution. This extracts the metal, and then the metal gets deposited on the cathode. While in the electro-refining process, the unrefined impure metals are present on the anodes, and because of electroplating, the pure refined metal gets deposited on the cathode.

Oxygen and Hydrogen Production

Electrolytic cells are used to produce oxygen in spacecraft and submarines and hydrogen fuel for various purposes. It is a process where electrolysis is used to break down water into its component parts, hydrogen and oxygen.

In conclusion, electrolytic cells are essential tools in many industries for their ability to drive chemical reactions through electrolysis. The applications of electrolytic cells in electroplating, the purification of metals, and the production of oxygen and hydrogen have made them indispensable in various fields.

Purification of Copper through Electrolysis

Copper is an essential metal used in various applications like electrical wiring, plumbing, and electronics. However, copper obtained from mines or ores is usually impure, containing other metals like lead, zinc, and silver. The impurities in copper can be removed through a process called electrolysis.

Electrolysis Process

In this process, an impure copper rod is made the anode, and a pure copper rod is made the cathode. Both the anode and cathode are immersed in an electrolyte solution of copper sulfate. When an electric current is passed through the solution, the copper ions move towards the cathode and get deposited on it, while the impurities settle at the bottom of the electrolytic cell as anode mud.

Multiple Cycles of Electrolysis

This process is repeated several times until the copper rod at the cathode becomes pure. The purity of the copper obtained through this process can be as high as 99.99%.

Uses of Purified Copper

The purified copper is then used in various applications like electrical wiring, plumbing, and electronics. It is important to note that electrolytic cells have revolutionized the purification and electroplating industry, providing a cost-effective and efficient way to produce high-quality metals.

In conclusion, the purification of copper through electrolysis is an essential process in the production of high-quality copper. The process involves the use of an electrolytic cell, where an impure copper rod is made the anode, and a pure copper rod is made the cathode. The copper ions move towards the cathode and get deposited on it, while the impurities settle at the bottom of the electrolytic cell as anode mud. This process is repeated several times until the copper rod at the cathode becomes pure. The purity of the copper obtained through this process can be as high as 99.99%. The purified copper is then used in various applications like electrical wiring, plumbing, and electronics.

Electroplating using Electrolytic Cells

Electroplating is a process that involves the deposition of a thin layer of metal onto a surface using an electrolytic cell. The process is commonly used in various industries, such as automotive, aerospace, and electronics, to improve the durability, appearance, and conductivity of materials.

Cathode and Anode

The electroplating process involves immersing a metal object, known as the cathode, in a solution containing a salt of the metal to be plated. An electrode of the metal to be plated, known as the anode, is also immersed in the solution. When a voltage is applied to the cell, metal ions are attracted to the cathode and deposit onto the surface.

Electrolyte Solution

The electrolyte solution used in electroplating depends on the metal to be plated. For example, copper plating uses a solution of copper sulfate, while nickel plating uses a solution of nickel sulfate. The concentration and pH of the electrolyte solution are also critical factors that affect the quality and thickness of the plated metal.

Current and Voltage

The current and voltage applied to the electrolytic cell are also essential factors that affect the electroplating process. The current density, which is the amount of current per unit area of the cathode, determines the thickness and quality of the plated metal. The voltage, on the other hand, determines the rate of the electroplating process.

Control Parameters

To achieve a high-quality and uniform plating, the electroplating process must be carefully controlled. Parameters such as the temperature, agitation, and current density must be optimized to ensure a consistent and defect-free plating.

Advantages of Electroplating

Electroplating has several advantages over other coating processes. It allows for the deposition of a thin layer of metal with high accuracy and precision, which is essential in industries such as electronics, where the thickness of the coating must be controlled to the micrometer level. Electroplating is also highly efficient, with a high deposition rate and low energy consumption. Additionally, the process is environmentally friendly, as it does not produce harmful byproducts.

In conclusion, electroplating using electrolytic cells is a common process used in various industries to improve the durability, appearance, and conductivity of materials. The process involves careful control of various parameters, such as the electrolyte solution, current density, and voltage, to ensure a high-quality and uniform plating. Electroplating has several advantages over other coating processes, making it an attractive option for many applications.

Other Applications of Electrolytic Cells

In addition to purification and electroplating, electrolytic cells have several other applications in various industries. Let's take a look at some of these applications.

Production of Chlorine and Sodium Hydroxide

One of the significant applications of electrolytic cells is the production of chlorine and sodium hydroxide. Chlorine and sodium hydroxide are widely used in the production of various products, including paper, textiles, and plastics. In the electrolytic cell, the electrolyte used is a solution of sodium chloride. When an electric current is passed through the solution, sodium chloride is broken down into its constituent ions, chlorine and sodium ions. The chlorine gas is produced at the anode, while the sodium hydroxide is produced at the cathode.

Production of Aluminum

Another important application of electrolytic cells is the production of aluminum. Aluminum is a widely used metal in the aerospace and automotive industries. The process of producing aluminum involves the electrolysis of aluminum oxide dissolved in molten cryolite. In the electrolytic cell, aluminum oxide is reduced to aluminum at the cathode, while oxygen is produced at the anode.

Production of Hydrogen Gas

Electrolytic cells can also be used in the production of hydrogen gas, which can be used as a fuel in fuel cells. In the electrolytic cell, water is electrolyzed to produce hydrogen gas and oxygen gas. The hydrogen gas is produced at the cathode, while the oxygen gas is produced at the anode.

Electrolysis of Minerals

Electrolytic cells can be used to extract metals from their ores. For example, copper can be extracted from its ore by the electrolysis of copper sulfate solution. In the electrolytic cell, copper ions are reduced to copper metal at the cathode, while the sulfate ions are oxidized to form oxygen gas and sulfuric acid at the anode.

Electrolysis of Saltwater

Electrolytic cells can also be used to desalinate saltwater. In the electrolytic cell, saltwater is electrolyzed to produce chlorine gas, hydrogen gas, and sodium hydroxide. The chlorine gas can be used for disinfection, while the hydrogen gas can be used as a fuel. The sodium hydroxide can be used for various industrial processes.

In conclusion, electrolytic cells have a wide range of applications in various industries, making them an essential tool in the production of many everyday products. From the production of chlorine and sodium hydroxide to the production of aluminum and hydrogen gas, electrolytic cells play a crucial role in the production of various products.

Related Products

- Multifunctional Electrolytic Electrochemical Cell Water Bath Single Layer Double Layer

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Thin-Layer Spectral Electrolysis Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- High Purity Gold Platinum Copper Iron Metal Sheets

Related Articles

- Understanding Flat Corrosion Electrolytic Cells: Applications, Mechanisms, and Prevention Techniques

- The Thermodynamic Paradox: Balancing Precision and Safety in Electrolytic Cells

- Understanding Electrolytic Cells and Their Role in Copper Purification and Electroplating

- Applications of H-Type Electrolytic Cell in Metal Extraction

- Exploring the Multifunctional Electrolytic Cell Water Bath: Applications and Benefits