Essential Considerations for Selecting a Warm Isostatic Press

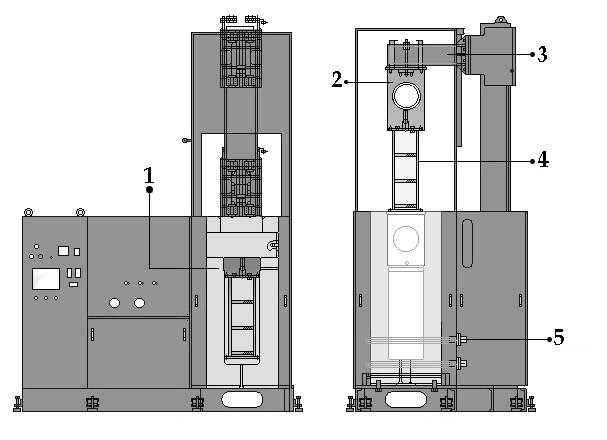

Cavity Size

The cavity size in a warm isostatic press is a critical dimension that directly impacts the process of placing and laminating blocks. This space is specifically designed to accommodate the packaging size of the blocks, ensuring that they fit securely within the press for optimal lamination. The cavity size must be carefully considered to avoid any potential issues during the lamination process, such as misalignment or incomplete bonding.

When evaluating cavity size, it is essential to take into account the dimensions of the blocks to be laminated. This includes both the length and width of the blocks, as well as any additional packaging materials that may be required. Ensuring that the cavity size is appropriately matched to the block dimensions will facilitate smoother operations and higher quality results.

Moreover, the design of the cavity should allow for easy insertion and removal of the blocks, without compromising the integrity of the lamination process. This ergonomic consideration not only enhances the efficiency of the operation but also reduces the risk of damage to the blocks and the press itself.

In summary, the cavity size is a fundamental aspect of selecting a warm isostatic press, as it directly influences the practicality and effectiveness of the lamination process. By carefully matching the cavity size to the block dimensions and packaging requirements, users can ensure a more streamlined and successful lamination experience.

Pressure Range and Accuracy

When selecting a warm isostatic press, one of the critical aspects to consider is the pressure range and accuracy of the equipment. The pressure range typically spans from 0 to 200 MPa, which is crucial for accommodating various materials and processes. This broad range ensures that the press can handle different types of materials, from soft polymers to hard metals, without compromising the structural integrity or desired properties of the final product.

Accuracy is another pivotal factor, often measured in terms of pressure tolerance, such as ±50 psi. High accuracy ensures that the pressure applied during the lamination process is consistent and precise, which is essential for achieving uniform results. Inconsistent pressure can lead to defects in the final product, such as uneven density or weak spots, which can compromise the overall quality and performance.

To illustrate the importance of these factors, consider the following table:

| Pressure Range | Accuracy (± psi) | Ideal For |

|---|---|---|

| 0 - 100 MPa | ±30 | Soft materials, low-stress applications |

| 100 - 200 MPa | ±50 | Hard materials, high-stress applications |

By understanding the pressure range and accuracy requirements, you can better match the equipment to your specific needs, ensuring optimal performance and product quality.

Temperature Considerations

When selecting a warm isostatic press, temperature considerations are paramount. The temperature range typically spans from 50℃ to 120℃, which is crucial for ensuring the proper processing of materials. This range allows for a variety of applications, from delicate operations requiring lower temperatures to more robust processes that demand higher heat.

Accuracy is another critical factor, with most systems maintaining a temperature accuracy of ±2℃. This precision ensures consistent results, minimizing variability in the final product. Achieving such accuracy requires advanced control systems and high-quality components, both of which contribute to the overall reliability of the press.

Uniformity of temperature distribution within the press is equally important. A uniform temperature ensures that all parts of the material being processed are exposed to the same conditions, preventing inconsistencies that could lead to defects. This uniformity is achieved through sophisticated heating elements and insulation techniques, which are integral to the design of modern warm isostatic presses.

In summary, the temperature considerations in a warm isostatic press involve a careful balance of range, accuracy, and uniformity, all of which are essential for delivering high-quality results.

Capacity and Ease of Use

When evaluating a warm isostatic press, the capacity to accommodate packaged blocks within the cavity size is a critical factor. This consideration directly impacts the efficiency and throughput of the pressing process. The cavity size must be sufficient to hold multiple blocks simultaneously, ensuring that the press can handle large-scale production needs without compromising on quality.

In addition to capacity, the ease of use of the operation interface is equally important. A user-friendly interface can significantly reduce the learning curve for operators, making the equipment more accessible and efficient. Features such as intuitive controls, clear indicators, and automated processes can enhance the overall user experience, minimizing the risk of errors and improving productivity.

To illustrate, consider the following table that outlines typical requirements for capacity and ease of use in a warm isostatic press:

| Feature | Requirement |

|---|---|

| Cavity Size | Sufficient to fit multiple packaged blocks simultaneously. |

| User Interface | Intuitive controls, clear indicators, automated processes. |

| Error Minimization | Reduced learning curve, fewer manual interventions. |

| Productivity | Enhanced throughput, efficient operation. |

By ensuring that both capacity and ease of use are optimally designed, manufacturers can achieve a balance between operational efficiency and user satisfaction, ultimately leading to better overall performance of the warm isostatic press.

Maintenance and Service

Ensuring the longevity and optimal performance of a warm isostatic press requires meticulous maintenance and service protocols. One critical aspect is the use of third-party instruments for detecting actual pressure and temperature. These instruments provide an independent verification of the readings from the press's internal sensors, ensuring accuracy and reliability. For instance, a calibrated pressure gauge from an external vendor can cross-check the internal pressure readings, while a thermocouple can verify the temperature settings.

In addition to pressure and temperature monitoring, the regular replacement of consumables such as seals is vital. Seals are integral to maintaining the press's integrity, preventing leaks, and ensuring consistent performance. Over time, seals degrade due to continuous exposure to high pressure and temperature, necessitating periodic replacement. This proactive approach not only extends the lifespan of the press but also prevents potential operational failures that could lead to costly downtime.

By integrating these maintenance practices, users can ensure that their warm isostatic press operates efficiently and reliably, meeting the stringent requirements of their applications.

Environmental Restrictions

When selecting a warm isostatic press, it's crucial to evaluate the environmental conditions under which the equipment will operate. Temperature and humidity sensitivity are paramount factors, as they directly influence the performance and lifespan of the press. For instance, high humidity can lead to corrosion, while extreme temperatures can affect the accuracy of the pressure and temperature controls.

Additionally, the load-bearing capacity of the plant where the press will be installed must be assessed. This ensures that the structural integrity of the building can support the weight of the press, especially during operation. Moreover, the installation area should be spacious enough to accommodate the press and allow for safe and efficient operation, maintenance, and potential future upgrades.

To summarize, understanding and addressing environmental restrictions not only ensures the optimal performance of the warm isostatic press but also safeguards the surrounding infrastructure and personnel.

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Warm Isostatic Press for Solid State Battery Research

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

Related Articles

- What is Isostatic Pressing Machine

- How Isostatic Presses Help Eliminate Defects in Materials

- Essential Equipment for Mass Production of Solid-State Batteries: Isostatic Press

- How to replace the rubber ring of isostatic press and what precautions should be taken

- Isostatic Pressing Technology in Solid-State Battery Production