Isostatic Pressing: An Overview

Table of Contents

Definition and working of isostatic pressing

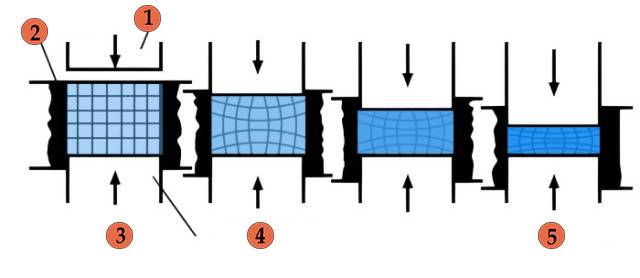

Isostatic pressing is a powder processing technique that uses fluid pressure to compact a part. The process involves placing metal powders in a flexible container, which serves as the mold. Fluid pressure is applied evenly over the entire outside surface of the container, causing it to press and form the powder into the desired geometry. Unlike other processes that exert forces on the powder through an axis, isostatic pressing applies pressure from all directions, resulting in uniform compaction.

Types of isostatic pressing: Cold, Warm, and Hot

Isostatic pressing can be categorized into three types: cold, warm, and hot.

-

Cold isostatic pressing involves compressing the powder at room temperature. This method is commonly used for materials that are sensitive to high temperatures or for applications where dimensional stability is crucial.

-

Warm isostatic pressing, as the name suggests, applies pressure to the powder at an elevated temperature. This technique allows for better plastic deformation of the material and can enhance the densification process.

-

Hot isostatic pressing involves subjecting the powder to high temperatures and pressures simultaneously. This method is effective for materials that require full densification and can help eliminate residual porosity.

Applications in aerospace, automotive, energy, medical, and electronics industries

Isostatic pressing finds applications in various industries due to its ability to produce dense and mechanically robust products. Here are some key sectors where isostatic pressing is utilized:

-

Aerospace: Isostatically pressed ceramics are used in aerospace applications for their high hardness, wear resistance, and thermal stability. The process enables the production of complex parts with superior structural integrity.

-

Automotive: Isostatic pressing plays a role in the manufacturing of ceramic parts for the automotive industry. These parts exhibit improved mechanical properties and are used in various components, such as engine parts and brake systems.

-

Energy: Isostatic pressing is employed in energy storage technologies like lithium-ion batteries and fuel cells. The demand for these technologies, coupled with the rise of electric vehicles and renewable energy systems, has increased the need for isostatic pressing.

-

Medical: The medical industry relies on isostatic pressing for the production of components used in medical devices and implants. The process ensures the creation of high-density materials with precise geometries and mechanical strength.

-

Electronics: Isostatic pressing is utilized in the electronics industry for the production of ceramic products such as tubes, fuse tubes, lighting tubes, and spark plug insulators. The process offers high-quality ceramic materials with excellent electrical insulation properties.

Isostatic pressing continues to evolve and find new applications across industries. Its ability to produce dense, uniform products with excellent mechanical properties makes it a valuable technique in the manufacturing and production of various materials.

Technological Advancements in Isostatic Pressing

Improved efficiency and effectiveness through advanced high-pressure isostatic press systems

Growing versatility and adaptability of isostatic pressing is enabling industries to seek advanced manufacturing solutions. This is projected to drive demand for isostatic pressing in the near future.

Increase in Adoption of Additive Manufacturing

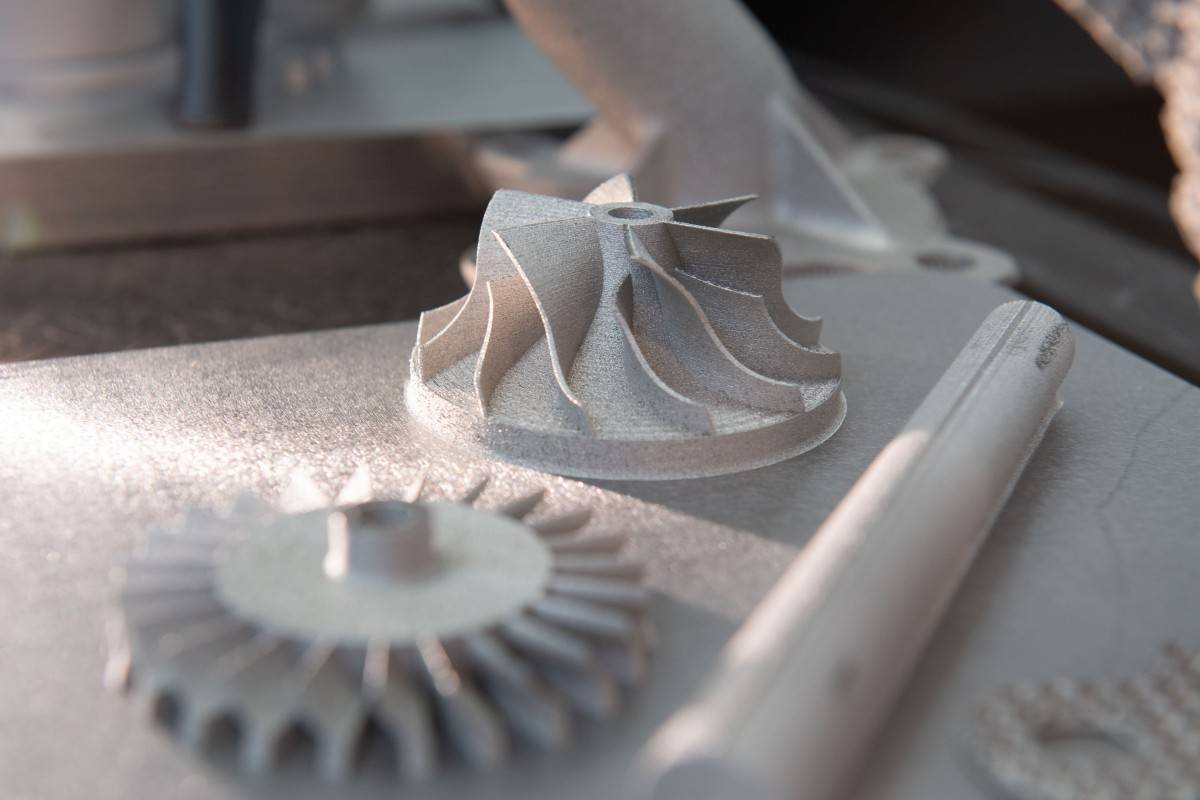

Additive manufacturing has gained traction in various industries in the past few years. This has led to an increase in demand for isostatic pressing as a post-processing technique. The combination of additive manufacturing and isostatic pressing provides a comprehensive solution for the production of complex and functional parts.

Isostatic pressing helps to achieve dimensional accuracy and stability for additive manufactured parts by subjecting the manufactured components to uniform pressure. Any residual stresses or distortions can be reduced or eliminated. This helps to maintain the intended dimensions and shape, ensuring the part meets the required specifications.

Role in powder metallurgy and production of complex-shaped components

Hot isostatic pressing plays an important role in powder metallurgy and 3D printing as well. KinTek has decades of experience creating both simple to complex components from powdered metal. KinTek technologies are a group of manufacturing processes used in the production of complex components; and now incorporate new, patent-pending techniques that combine 3D printing with well-established near net shape and selective surface net shape techniques. These solutions dramatically reduce the manufacturing time and production cost of a part compared to producing the same part using 3D printing alone.

Advancements in powder metallurgy techniques, such as improved powder fragmentation, alloy development, and binder systems enable the production of complex-shaped components with precise dimensional control and desirable microstructures. This factor contributes to the growth of the global isostatic pressing market size.

Expanded range of applications due to ongoing R&D

Technological advancements and ongoing R&D have expanded the range of applications for isostatic pressing, as it is widely used in the production of aerospace and automotive components, medical implants, semiconductor materials, and even 3D printing.

Industries such as aerospace, automotive, and medical require complex parts with specific geometries, and isostatic pressing offers a solution for producing these parts with superior structural integrity.

By applying hydrostatic pressure to the printed part, its density and mechanical strength can be improved, which is driving adoption in sectors that utilize 3D printing technology.

The isostatic press industry is seeing advances in process automation and control systems, reducing human error and ensuring higher product quality.

With growing concerns about sustainability and environmental impact, the isostatic pressing market is moving towards greener practices by optimizing resource utilization and reducing material waste in the stamping process.

Isostatic pressing has applications in energy storage technologies such as lithium-ion batteries and fuel cells, which, coupled with the popularity of electric vehicles and renewable energy systems, has increased the demand for isostatic pressing technologies.

Increased Adoption of Isostatic Pressing in Additive Manufacturing

Role of isostatic pressing as a post-processing technique

Additive manufacturing helps in providing compositional variations within the manufactured part due to uneven powder distribution or segregation. Isostatic pressing helps mitigate these issues by applying uniform pressure and promoting better material homogeneity throughout the component. This ensures consistent material properties and eliminates potential weak points or inhomogeneities, leading to greater usage of isostatic pressing in the market.

Benefits: dimensional accuracy, stability, material homogeneity

Isostatic pressing plays a crucial role in achieving dimensional accuracy and stability for additive manufactured parts. By subjecting the manufactured components to uniform pressure, any residual stresses or distortions can be reduced or eliminated. This helps to maintain the intended dimensions and shape, ensuring the part meets the required specifications.

Compatibility with various materials used in additive manufacturing

Additive manufacturing is continuously expanding its material capabilities, including the use of advanced alloys, ceramics, and composites. As isostatic pressing can be applied to various materials used in additive manufacturing, it enables the production of high-performance components with improved mechanical properties.

The growing versatility and adaptability of isostatic pressing is enabling industries to seek advanced manufacturing solutions. This is projected to drive the demand for isostatic pressing in the near future.

Overall, the combination of additive manufacturing and isostatic pressing provides a comprehensive solution for the production of complex and functional parts. With its ability to improve dimensional accuracy, stability, and material homogeneity, isostatic pressing is becoming increasingly adopted in the additive manufacturing industry.

Hot Isostatic Pressing (HIP): Enhancing Material Properties

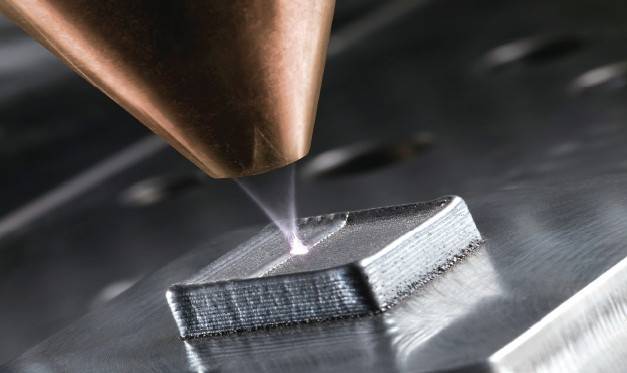

Hot Isostatic Pressing (HIP) is a material treatment process that involves the simultaneous application of high temperature and pressure to metals and other materials for a specified amount of time. This process is used to improve the mechanical, physical, and chemical properties of the materials.

HIP's contribution to the largest global isostatic pressing market share

The hot isostatic pressing (HIP) market holds the largest market share in the global isostatic pressing industry. This growth can be attributed to the increasing demand for reliable, high-performance components in industries such as aerospace, automotive, medical, energy, and manufacturing. HIP technology provides advanced manufacturing solutions that enhance material properties and component performance. Furthermore, advancements in materials, alloys, and improvements in HIP equipment technology further support the expansion of the market. The industry's focus on cost efficiency, waste reduction, and sustainable manufacturing practices also contributes to the growth of the HIP market.

Improvements in mechanical, physical, and chemical properties of materials

Hot isostatic pressing (HIP) significantly improves the mechanical, physical, and chemical properties of materials. It achieves near-net-shape densification of materials, improving density and reducing porosity. This leads to components with superior strength and performance. HIP eliminates residual stresses, improves fatigue resistance, enhances corrosion resistance, and achieves fine-grained microstructures, resulting in materials with superior performance characteristics. Moreover, HIP heals and eliminates defects in materials by subjecting components to high temperature and pressure, effectively removing voids, cracks, and other internal imperfections. This improves the structural integrity and reliability of the parts.

Applications in manufacturing of critical components

HIP has a wide range of applications in various industries, including aerospace, automotive, energy, medical, and tooling. It is used for manufacturing critical components such as turbine blades, engine parts, medical implants, tool steels, and advanced materials like super alloys and ceramics. The rise in demand for high-performance materials and complex-shaped components is expected to drive the adoption of HIP in the near future.

Hot Isostatic Pressing (HIP) plays a crucial role in improving the quality and performance of components produced by powder-based Additive Manufacturing (AM). It consolidates metal powders and metal matrix composites to produce fully dense components, eliminates porosity in sintered parts, produces metal-clad parts through diffusion bonding, and eliminates defects in castings. By utilizing HIP in the production of AM parts, the quality and performance of these components are assured and increased.

In conclusion, Hot Isostatic Pressing (HIP) is a valuable material treatment process that enhances the mechanical, physical, and chemical properties of metals and other materials. Its contributions to the global isostatic pressing market, improvements in material properties, and applications in critical component manufacturing make it a crucial technology for various industries. By utilizing HIP, businesses can achieve superior performance and reliability in their products, ensuring success in today's competitive market.

Regional Outlook of the Isostatic Pressing Industry

Asia Pacific as the leading region in the global market

The Asia Pacific region has emerged as the leading region in the global isostatic pressing market. The market in this region is projected to witness significant growth, primarily driven by factors such as large manufacturing bases, favorable government initiatives, and low labor costs. Countries like China, Japan, India, and South Korea are experiencing a rise in demand for high-performance components, which is further contributing to the growth of the market in this region.

Factors contributing to market growth in Asia Pacific

The growth of the isostatic pressing market in Asia Pacific can be attributed to various factors. One of the key factors is the rapid rise in demand for products with short production cycles in the healthcare sector. Isostatic pressing technology enables the production of dense and uniform products with excellent mechanical properties, making it ideal for the healthcare industry.

Another significant factor is the increasing use of additive manufacturing or 3D printing technology in the automotive sector. This technology has gained popularity due to its cost-effectiveness in manufacturing low-cost spare parts. The demand for such technology is driving the growth of the isostatic pressing market in Asia Pacific.

Emerging markets: North America and Europe

North America and Europe are also emerging markets for the isostatic pressing industry. These regions have established manufacturing industries in sectors such as aerospace & defense, automotive, and energy, which are driving the development of the isostatic pressing market.

In North America, the market is dominated by established industries, and it is expected to continue to lead in terms of revenue during the forecast period. Europe is also witnessing growth, with various industries embracing isostatic pressing technology for the production of high-quality components.

Overall, the global isostatic pressing market is projected to reach a valuation of $7.97 billion by 2027, with a CAGR of 6.0% from 2020 to 2027. The market is expected to witness steady growth, driven by factors such as the demand for products with short production cycles in the healthcare sector and the increasing use of additive manufacturing technology in the automotive sector.

By application, the aerospace & defense segment accounted for the major share in the global isostatic pressing market in 2019. However, the automotive segment is expected to witness the highest CAGR during the forecast period.

The regional outlook of the isostatic pressing industry highlights the significant growth potential in Asia Pacific, along with the emergence of North America and Europe as promising markets. These regions offer lucrative opportunities for manufacturers and stakeholders in the isostatic pressing industry.

If you are interested in this product you can browse our company website: https://kindle-tech.com/product-categories/isostatic-press, we always insist on the principle of quality first. During the production process, we strictly control every step of the process, using high quality materials and advanced production technology to ensure the stability and durability of our products. to ensure that their performance meets the highest standards. We believe that only by providing customers with excellent quality can we win their trust and long-term cooperation.

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

Related Articles

- Understanding the Isostatic Pressing Process and its Types

- Selecting Isostatic Pressing Equipment for High-Density Molding

- Isostatic Pressing Technology: Principles, Classification, and Applications

- Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

- Comprehensive Guide to Isostatic Pressing: Types, Processes, and Features(3)