Pre-Operation Checks

Ensure Water, Electricity, and Gas Conditions

Before initiating the operation of the vacuum furnace, it is imperative to confirm that the essential utilities—water, electricity, and gas—are functioning within the specified parameters. This preliminary check ensures the safety and efficacy of the furnace operation.

Firstly, the electrical supply must be meticulously verified. The voltage should be precisely 380V, with an allowable deviation of no more than 10%. Any significant deviation from this standard could potentially disrupt the furnace's performance and pose safety risks.

Secondly, the gas pressure must be maintained at a steady 0.6MPa. This pressure level is crucial for the proper functioning of the furnace's gas-related systems, ensuring that all processes operate smoothly and efficiently.

Lastly, the water pressure must meet or exceed the minimum requirement of 0.5MPa. Adequate water pressure is essential for the cooling systems within the furnace, preventing overheating and ensuring the longevity of the equipment.

| Utility | Required Condition | Importance |

|---|---|---|

| Electricity | 380V ± 10% | Ensures stable operation and safety |

| Gas | 0.6MPa | Essential for smooth functioning of gas-related systems |

| Water | ≥ 0.5MPa | Crucial for cooling systems, preventing overheating and equipment longevity |

Ensuring these conditions are met before operation is not merely a procedural step but a critical safety measure that safeguards both the equipment and the personnel involved in the process.

Check and Clean Heating Room

Before placing any materials inside the heating room, it is imperative to conduct a thorough inspection and cleaning process. This ensures that the environment is free from any contaminants that could potentially affect the integrity of the materials and the operation of the vacuum furnace.

Key Elements to Check:

- Debris: Ensure the room is clear of any loose particles or foreign objects that could interfere with the heating process.

- Dust: Dust accumulation can compromise the vacuum integrity and should be meticulously removed.

- Oil: Any traces of oil can lead to unwanted reactions within the furnace and must be eliminated.

- Water: Moisture can cause corrosion and other detrimental effects. The room should be completely dry.

Materials Preparation:

The materials intended for placement within the heating room should also undergo a cleaning process. They must be:

- Dry: Completely free from moisture to prevent any unwanted chemical reactions or damage during the heating process.

- Clean: Free from dust, oil, and other contaminants to ensure the highest quality results.

By adhering to these meticulous cleaning and inspection protocols, you can significantly enhance the efficiency and reliability of the vacuum furnace operation.

Operation Sequence

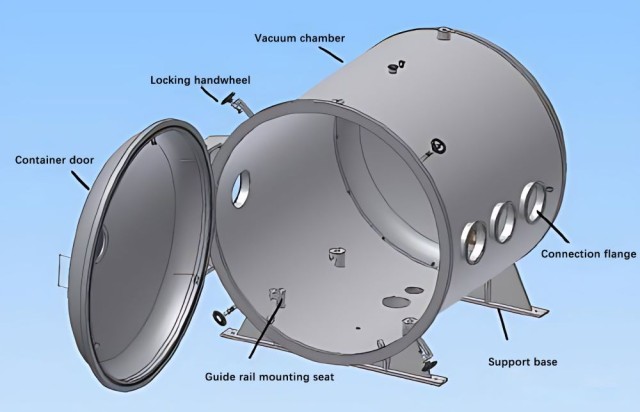

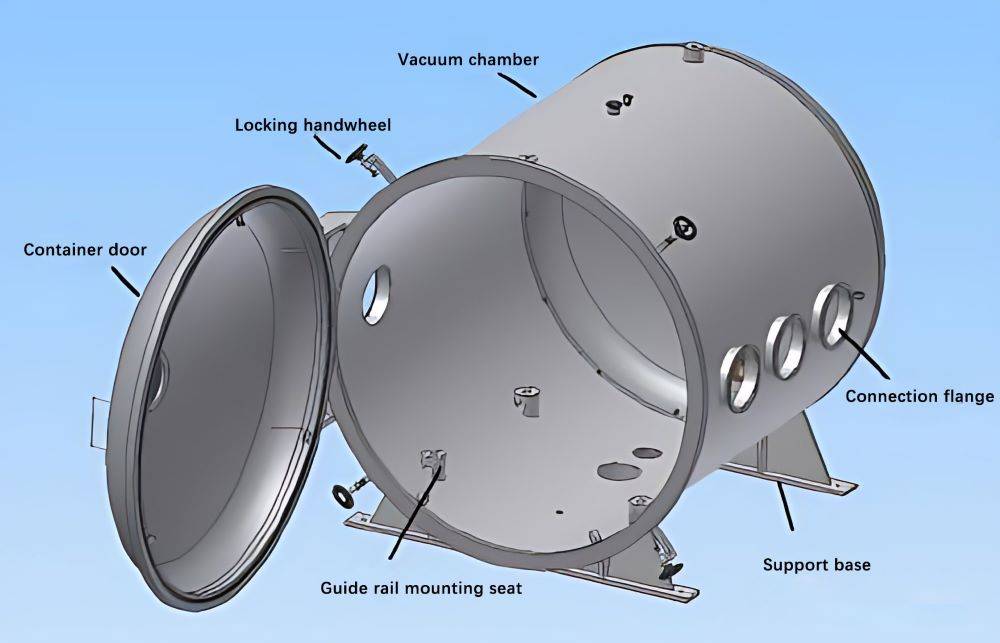

Loading and Initial Setup

Once the materials have been securely loaded into the vacuum furnace, the initial setup process begins. This step is crucial to ensure that the furnace is prepared for the subsequent operations. The first action is to set the control knob to the 'door off' position, which isolates the furnace chamber from any external pressures. This isolation is essential to maintain the integrity of the vacuum environment within the chamber.

Next, the mechanical pump is activated. This pump plays a pivotal role in the initial phase of vacuum creation by removing the bulk of the atmospheric gases from the furnace chamber. Simultaneously, the coarse pumping valve is opened to facilitate this process. The combined operation of the mechanical pump and the coarse pumping valve accelerates the evacuation of gases, thereby expediting the establishment of the initial vacuum.

Finally, the vacuum furnace power supply is turned on. This step energizes the furnace, enabling it to commence its internal processes. The power supply is critical for the subsequent stages, including the heating and cooling cycles, ensuring that the furnace operates efficiently and safely throughout the entire procedure.

By following these steps in sequence, the vacuum furnace is properly initialized, setting the stage for the next phases of the operation.

Achieving High Vacuum

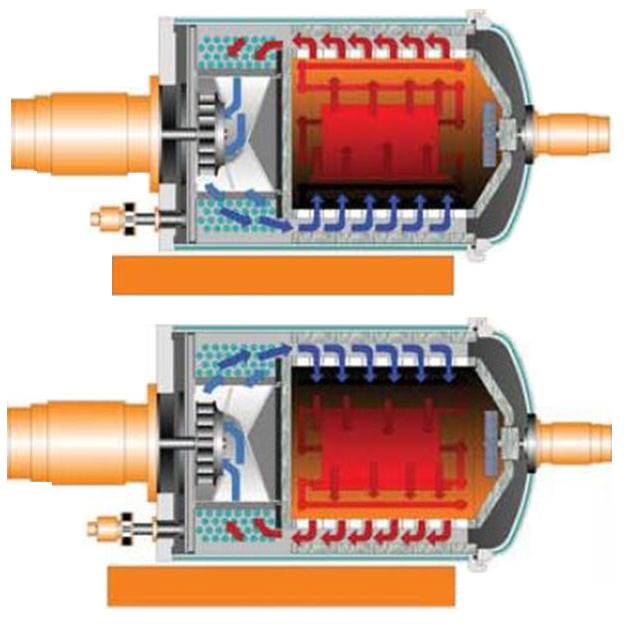

Achieving high vacuum in a laboratory setting requires meticulous attention to detail, as the materials exposed to the vacuum must be rigorously evaluated for their outgassing and vapor pressure properties. For instance, oils, greases, and rubber or plastic gaskets used as seals for the vacuum chamber must not emit gases when exposed to the vacuum, as these gases would hinder the attainment of the desired vacuum level. Often, all surfaces exposed to the vacuum must undergo high-temperature baking to eliminate adsorbed gases.

When the vacuum reaches a level higher than 1000 Pa, it is imperative to activate the Roots pump. This pump plays a crucial role in further reducing the pressure within the chamber. Once the vacuum surpasses 7 Pa, the pre-stage valve and dispersing pump should be opened. Prior to initiating the dispersing pump, it is essential to preheat it for a duration of 90 minutes. This preheating process ensures that the pump operates efficiently and minimizes the risk of outgassing, which could compromise the vacuum integrity.

The sequence of operations is critical to maintaining the integrity of the vacuum. The steps outlined ensure that the system progresses through the necessary stages to achieve and sustain the high vacuum required for various laboratory processes. Each component, from the Roots pump to the dispersing pump, must be managed with precision to avoid leaks or the release of unwanted gases.

Heating and Process Completion

Once the furnace chamber achieves the desired operating vacuum, initiate the heating process. This phase is crucial as it directly impacts the quality and integrity of the materials being processed. The heating process typically involves precise temperature control and monitoring to ensure uniformity and consistency.

As the heating process progresses, continuous monitoring is essential to detect any anomalies or deviations from the expected parameters. This ensures that the process remains within the safe and optimal operating range. If any issues are detected, corrective actions can be taken promptly to prevent potential damage or degradation of the materials.

Upon completion of the heating process, a 'process completion' alarm will sound, signaling the end of the cycle. At this point, the heating will automatically cease, and the system will transition to a standby mode. This alarm serves as a critical notification, alerting operators that the process has concluded and that it is safe to proceed with the next steps in the operation sequence.

The automatic cessation of heating upon process completion is a safety feature designed to prevent overheating and potential damage to the furnace or the materials being processed. It ensures that the system operates within predefined parameters, maintaining the integrity and reliability of the laboratory vacuum furnace.

Cooling Procedures

Natural Cooling

For natural cooling, allow the equipment to cool down gradually without any external intervention. This method is particularly useful for maintaining the integrity of the materials being processed. Once the temperature has stabilized and the equipment has cooled sufficiently, proceed to close the high valve, dispersion pump, and Roots pump. These components should remain closed until the furnace has reached ambient temperature.

To ensure the furnace pressure is balanced with the atmospheric pressure, open the manual bleeder valve. This step is crucial for preventing any pressure imbalances that could affect the performance of the furnace or the quality of the materials. The manual bleeder valve allows for a controlled release of pressure, ensuring a smooth transition from vacuum conditions to atmospheric conditions.

| Step | Action | Purpose |

|---|---|---|

| 1 | Allow natural cooling | Maintain material integrity |

| 2 | Close high valve | Prevent uncontrolled pressure changes |

| 3 | Close dispersion pump | Ensure equipment is not operating unnecessarily |

| 4 | Close Roots pump | Prevent unnecessary energy consumption |

| 5 | Open manual bleeder valve | Equalize furnace pressure with atmospheric pressure |

By following these steps, you ensure that the natural cooling process is both efficient and safe, protecting both the equipment and the materials being processed.

Forced Cooling

Forced cooling is a critical step in the vacuum furnace operation process, designed to expedite the cooling of the furnace chamber and its contents. After the process completion, it is imperative to systematically close several key components to ensure safe and efficient cooling. Begin by closing the vacuum gauge, high valve, rough pumping valve, and dispersing pumps. These actions prevent any unintended gas flow or pressure changes during the cooling phase.

Next, the furnace is filled with an inert gas, typically nitrogen or argon, to create a stable environment that safeguards the materials from oxidation or contamination. Simultaneously, the cooling fan is activated to facilitate rapid heat dissipation. The combination of inert gas filling and active fan cooling significantly reduces the time required for the furnace to reach a safe operating temperature.

Once the cooling process is complete, the manual bleeder valve is opened to equalize the pressure within the furnace chamber with the atmospheric pressure. This step is crucial to prevent any pressure differential that could damage the furnace or its contents. The meticulous sequence of operations ensures that the forced cooling process is both effective and safe, adhering to the highest standards of laboratory vacuum furnace procedures.

Post-Operation

Final Steps and Cleanup

After the furnace has sufficiently cooled, proceed to open the furnace door with caution. Carefully remove the processed materials, ensuring that no debris is left behind. Following this, it is crucial to systematically shut down the utilities. Start by closing the water supply, followed by the electrical connections, and finally, the gas lines.

Additionally, special attention must be given to the temperature of the 'dispersing pump'. Wait until it has cooled down to room temperature before taking further action. Once the 'dispersing pump' is at ambient temperature, you can safely close the 'mechanical pump' and the 'pre-stage valve'. This sequence ensures that all components are properly cooled and shut down, preventing any potential damage or safety hazards.

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Dental Porcelain Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace