Chemistry is often a battle between the reaction you want to create and the vessel you are trying to contain it in.

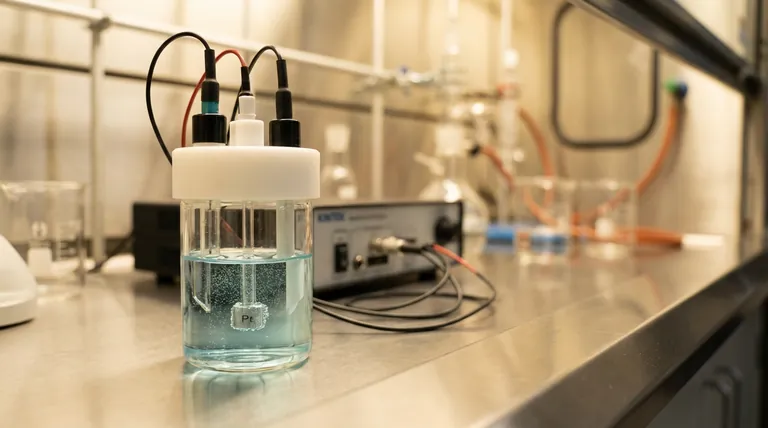

In electrochemistry, this tension is amplified. You are driving non-spontaneous reactions, forcing electrons to move where they usually wouldn't, often creating harsh environments involving corrosive electrolytes and fluctuating temperatures.

The scientist faces a paradox:

- You need to see the reaction (requiring transparency).

- You need to contain the aggression (requiring inertness).

This is why the design of a standard multifunctional electrolytic cell is not random. It is a specific engineering response to the physical demands of the laboratory.

The Glass Paradox

We humans are visual creatures. We trust what we can see.

In a "black box" experiment, uncertainty breeds. Is the electrode bubbling? Has the solution changed color? Is there precipitation?

This is why the cell body is constructed from High Borosilicate Glass.

It is not merely about aesthetics; it is about data verification. Borosilicate glass offers a specific set of defenses that allow the scientist to remain an observer, not a participant in the reaction:

- Chemical Stability: It refuses to interact with the vast majority of electrolytes. It does not leach impurities that could skew sensitive voltammetry readings.

- Thermal Shock Resistance: Reactions generate heat. Standard glass shatters under rapid temperature shifts; borosilicate expands and contracts with a stoicism that keeps the containment breach-proof.

The glass body is the window into the chaos. It provides the psychological assurance that the experiment is proceeding as planned.

The Stoic Ceiling

While the body must be transparent, the lid must be functional.

The lid is the control center. It must hold the "Holy Trinity" of electrochemistry—the Working, Counter, and Reference electrodes—in perfect alignment, millimeter-perfect, without degrading over time.

For this, we turn to Polytetrafluoroethylene (PTFE), often known as Teflon.

PTFE is the engineer's answer to corrosion. It is famously chemically inert. Vapors rising from a heated acidic electrolyte might attack a metal lid or degrade a rubber seal, but they slide off PTFE.

Beyond resistance, PTFE offers machinability.

To create a precise three-electrode system, the lid requires tight tolerances. PTFE is soft enough to be machined into complex geometries for airtight sealing but rigid enough to hold heavy electrodes in place. It bridges the gap between the chaotic internal environment and the ordered external laboratory.

The Trade-Offs of Survival

There are no perfect materials, only perfect compromises.

The standard Borosilicate/PTFE combination covers 90% of use cases. But engineering requires acknowledging the edge cases.

If your research involves Hydrofluoric Acid (HF), the rules change. HF eats glass. In this scenario, the transparency of borosilicate becomes a liability rather than an asset.

The solution is an All-PTFE Cell Body.

You gain total survival. You lose visibility.

It is a trade-off that must be made consciously. You are trading the ability to see the reaction for the ability to contain it.

The Ritual of Reset

A high-performance electrolytic cell is not a disposable consumable; it is a precision instrument.

Like a surgeon cleaning their tools, the care taken after the experiment defines the success of the next experiment.

- Drain immediately: Never store electrolytes in the cell long-term.

- Isolate: Store the solution in a separate sealed container.

- Purify: Wash and dry the cell thoroughly to prevent "ghost" readings from previous runs.

Summary of Material Logic

The choice between materials is a choice between priorities.

| Component | Material | Primary Psychological & Physical Function |

|---|---|---|

| Cell Body | High Borosilicate Glass | Visibility & Stability. Allows visual monitoring while resisting thermal shock. |

| Lid | PTFE | Control & Inertness. Provides a corrosion-proof platform for precise electrode mounting. |

| Special Body | Full PTFE | Survival. Essential for glass-etching acids (HF), sacrificing visibility for durability. |

Designing Your Experiment

At KINTEK, we understand that equipment should be the least of your worries. Your focus belongs on the data, not on whether your vessel can withstand the chemistry.

We design our electrolytic cells to be the silent partner in your research—chemically invisible and structurally sound. Whether you need the standard transparency of borosilicate or the ruggedness of a custom PTFE setup, we have the architecture to contain your science.

Let us help you achieve precise results. Contact Our Experts to discuss your specific chemical environment and find the ideal cell configuration for your laboratory.

Visual Guide

Related Products

- Super Sealed Electrolytic Electrochemical Cell

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell for Coating Evaluation

- Electrolytic Electrochemical Cell with Five-Port

- Electrolytic Electrochemical Cell Gas Diffusion Liquid Flow Reaction Cell

Related Articles

- The Architecture of Control: Mastering the Super-Sealed Electrolytic Cell

- The Architecture of Precision: Why the Invisible Details Define Electrochemical Success

- The Silence of the Seal: Why Electrochemical Precision is a Battle Against the Atmosphere

- The Architecture of Precision: Mastering the Five-Port Water Bath Electrolytic Cell

- The Glass Heart of the Experiment: Precision Through Systematic Care