We are psychologically wired to respect extremes.

When buying a car, we look at top speed. When buying a computer, we look at processing power. And when selecting a laboratory tube furnace, the instinct is to look immediately at one number: Maximum Operating Temperature.

It feels safe to buy the "strongest" option. If a furnace can reach 1200°C, surely it can handle a 900°C experiment with ease.

But this logic contains a dangerous blind spot.

In the delicate world of material science, heat is not just an intensity; it is a geography. The success of your process usually relies less on how hot the furnace can get, and more on where that heat actually lives.

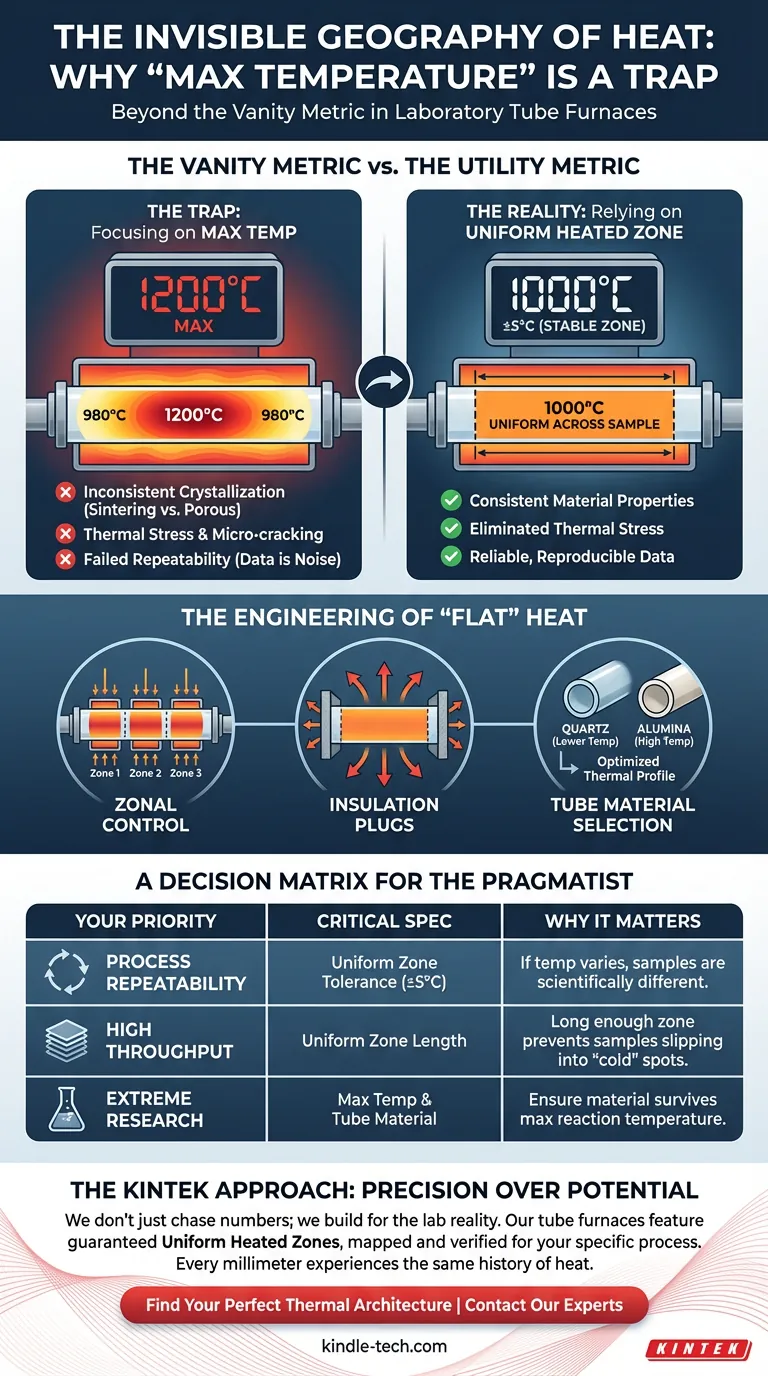

The Vanity Metric vs. The Utility Metric

The "range" of a TF tube furnace is technically defined by two parameters. However, buyers often treat them as one.

- Maximum Operating Temperature: The ceiling.

- Uniform Heated Zone: The floor (where the work actually happens).

Focusing on the first parameter is easy. It is a single, impressive number (often 1000°C or more).

Focusing on the second requires an engineer's mindset. It asks a harder question: Inside this tube, how much space actually delivers the physics I need?

The Chaos of Thermal Gradients

Imagine placing a 10cm ceramic sample into a furnace set to 1000°C.

If your furnace has high power but poor design, the center of your sample might hit 1000°C, while the edges—closer to the uninsulated ends of the tube—hover at 980°C.

To the naked eye, the sample looks glowing and hot. To the microstructure of the material, this is a catastrophe.

- Inconsistent Crystallization: One end of the sample sinters; the other remains porous.

- Thermal Stress: The temperature gradient creates mechanical tension, leading to micro-cracking.

- Failed Repeatability: An experiment run today cannot be compared to one run next week if the sample placement shifts by merely a few millimeters.

This is why the Uniform Heated Zone is the only metric that truly matters. It defines the specific length within the tube where temperature variation is strictly controlled (typically ±5°C).

Outside this invisible zone, your data is noise.

The Engineering of "Flat" Heat

Creating a stable thermal environment is an act of resistance against thermodynamics. Heat wants to flow to cold areas. It wants to escape through the tube ends.

Achieving a long, flat uniform zone requires sophisticated architecture:

- Zonal Control: High-end furnaces often use multiple independently controlled heating zones to compensate for heat loss at the ends.

- Insulation Plugs: Physical barriers are essential to stop radiative heat loss from the tube apertures.

- Tube Material: The interaction between the heating element and the work tube (Quartz vs. Alumina) dictates the thermal profile.

There is a trade-off here. A longer physical furnace does not automatically grant a longer uniform zone. Length without control just creates a larger gradient.

Selecting for Reality, Not Potential

When specifying your equipment, you are engaging in a balance of constraints.

Higher temperatures cost more money (exotic elements, power consumption). Longer uniform zones cost more engineering effort.

The goal is to match the furnace's "geometry of heat" to your sample's physical footprint.

A Decision Matrix for the Pragmatist

| Your Priority | The Critical Spec | Why It Matters |

|---|---|---|

| Process Repeatability | Uniform Zone Tolerance | If the temp varies >±5°C, your "identical" samples are scientifically different. |

| High Throughput | Uniform Zone Length | You need a zone long enough to hold multiple samples without them slipping into the "cold" spots. |

| Extreme Research | Max Temp & Tube Material | Ensure the tube material (e.g., Alumina) can survive the max temp needed for the reaction. |

The KINTEK Approach

At KINTEK, we appreciate the romance of high numbers, but we build for the reality of the lab bench.

A furnace is not a blunt instrument; it is a precision tool. We specialize in tube furnaces where the Uniform Heated Zone is mapped, verified, and guaranteed. Whether you are sintering advanced ceramics or conducting atmosphere-controlled annealing, our equipment is designed to ensure that every millimeter of your sample experiences the exact same history of heat.

Don't let a temperature gradient ruin months of research.

Ready to find the perfect thermal architecture for your lab? Contact Our Experts

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab