Types of PECVD

Radio Frequency Enhanced Plasma Chemical Vapor Deposition (RF-PECVD)

Radio Frequency Enhanced Plasma Chemical Vapor Deposition (RF-PECVD) is a sophisticated technique for the deposition of polycrystalline thin films onto substrates. This method leverages the power of glow discharge plasma to influence the low-pressure chemical vapor deposition process, thereby enhancing the quality and efficiency of film formation. The inception of RF-PECVD can be traced back to 1994 when Nippon Konica first proposed the method, naming it after its predominant use of radio-frequency (RF) for plasma generation.

The RF-PECVD process is distinguished by its use of two primary coupling methods for the radio-frequency electric field: inductive coupling and capacitive coupling. These methods play a crucial role in the efficiency and effectiveness of the plasma generation, which in turn significantly impacts the deposition process.

Inductive coupling involves the use of an inductor to transfer energy to the plasma, creating a magnetic field that ionizes the gas molecules. This method is particularly effective in generating a high-density plasma, which is essential for rapid and uniform film deposition. On the other hand, capacitive coupling utilizes the electric field between two electrodes to energize the plasma. This approach is advantageous for its ability to maintain a stable plasma environment, ensuring consistent film properties.

The dual coupling methods employed in RF-PECVD offer a versatile approach to plasma generation, allowing for adjustments based on specific requirements of the deposition process. This flexibility makes RF-PECVD a preferred choice for various applications in semiconductor manufacturing and other advanced technologies.

Very High Frequency Plasma Chemical Vapor Deposition (VHF-PECVD)

When thin films are prepared using Radio Frequency Plasma Enhanced Chemical Vapor Deposition (RF-PECVD), achieving low-temperature deposition necessitates the use of diluted silane as the reaction gas. This approach, however, significantly limits the deposition rate. In contrast, Very High Frequency Plasma Chemical Vapor Deposition (VHF-PECVD) technology offers a substantial improvement in this regard. The VHF-excited plasma operates at a much lower temperature and boasts a higher electron density compared to conventional RF-generated plasma. This unique characteristic enables VHF-PECVD to achieve a notably higher deposition rate, making it a preferred choice for various practical applications.

The enhanced performance of VHF-PECVD can be attributed to the lower operating temperature and the elevated electron density within the plasma. These factors collectively contribute to a more efficient dissociation of the reaction precursors, leading to a faster deposition process. Unlike RF-PECVD, which relies on capacitive coupling with its inherent limitations in plasma density and precursor dissociation, VHF-PECVD leverages inductive coupling to generate a denser plasma. This density translates into a more efficient reaction, ultimately resulting in faster and more effective film growth.

Moreover, the broader applicability of VHF-PECVD stems from its ability to maintain low substrate temperatures while simultaneously achieving high deposition rates. This dual advantage is particularly beneficial in industries where the thermal sensitivity of the substrates is a critical concern. By minimizing thermal stress on the substrates, VHF-PECVD ensures the integrity and quality of the deposited films, thereby extending its utility across a wide range of materials and applications.

In summary, VHF-PECVD stands out as a superior alternative to RF-PECVD due to its ability to significantly enhance the deposition rate without compromising on temperature control. This technology not only addresses the limitations of RF-PECVD but also opens up new possibilities for the efficient and effective deposition of thin films in various industrial contexts.

Dielectric Blocking Discharge Enhanced Chemical Vapor Deposition (DBD-PECVD)

Dielectric Blocking Discharge Enhanced Chemical Vapor Deposition (DBD-PECVD) is a specialized form of non-equilibrium gas discharge characterized by the insertion of an insulating medium into the discharge space. This configuration is also referred to as a dielectric barrier discharge or silent discharge. The unique setup of DBD-PECVD amalgamates the expansive, uniform discharge properties of glow discharge with the high-pressure operational capabilities of corona discharge. This combination facilitates a controlled and efficient deposition process, making it increasingly popular for the synthesis of silicon thin films.

In the context of thin film preparation, DBD-PECVD offers several advantages. The presence of the dielectric barrier allows for a more stable and uniform discharge, which is crucial for the even distribution of deposited material. This stability is particularly beneficial in maintaining the quality and consistency of the silicon thin films. Additionally, the high-pressure operation mode inherent to DBD-PECVD enables efficient gas utilization, further enhancing the deposition rate and overall productivity of the process.

The integration of DBD-PECVD into thin film manufacturing processes underscores its potential to revolutionize the industry. By leveraging the synergistic effects of large-space uniform discharge and high-pressure operation, DBD-PECVD not only optimizes the deposition process but also opens new avenues for the development of advanced materials with superior properties. As research and application of this technology continue to evolve, its role in the fabrication of high-performance silicon thin films is expected to grow significantly.

Microwave Electron Cyclotron Resonance Plasma Enhanced Chemical Vapor Deposition (MWECR-PECVD)

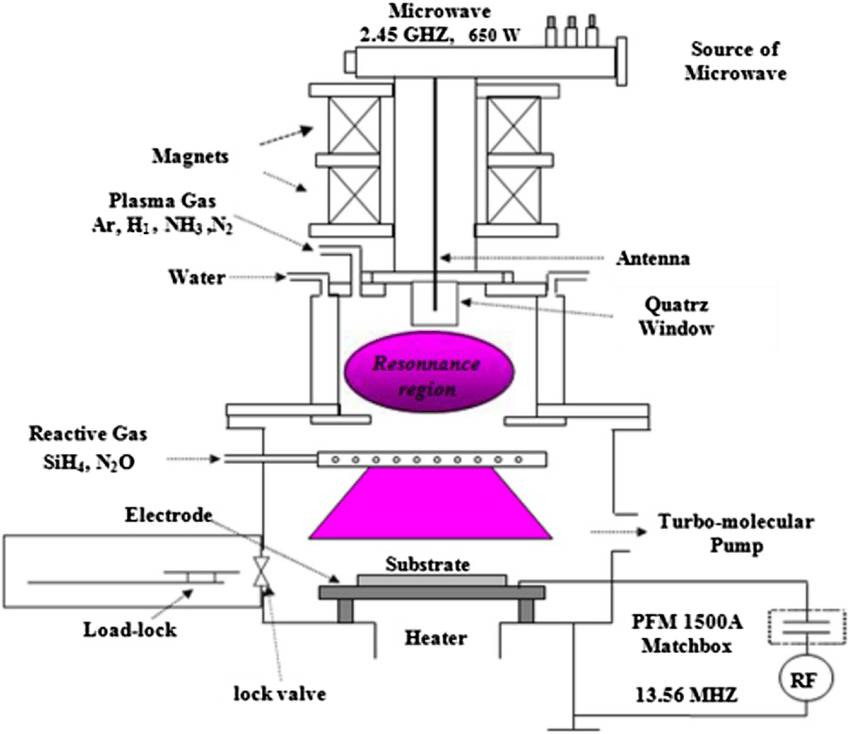

Microwave Electron Cyclotron Resonance Plasma Enhanced Chemical Vapor Deposition (MWECR-PECVD) is a sophisticated gas-phase chemical reaction that leverages the cyclotron resonance effect of electrons in microwave and magnetic fields to generate a highly active and dense plasma under vacuum conditions. This advanced technology is particularly renowned for its ability to produce high-quality thin films at remarkably low temperatures, making it a preferred method in various industrial applications.

The plasma in MWECR-PECVD is initiated through electromagnetic wave excitation, with a common operating frequency of 2450 MHz. By modulating the electromagnetic wave photon energy, the energy levels and survival lifetimes of the gas particles decomposed into plasma can be precisely controlled. This direct manipulation significantly influences the formation of the thin films and the subsequent surface treatment mechanisms, ultimately dictating the structural integrity, material properties, and long-term stability of the deposited films.

In essence, MWECR-PECVD represents a cutting-edge approach to thin film deposition, offering unparalleled control over the fundamental processes that govern film formation and quality. This method's ability to fine-tune the plasma characteristics ensures that the resulting films meet stringent performance criteria, making it a cornerstone technology in the realm of thin film science and engineering.

Basic Structure of PECVD Equipment

Fundamentals of the PECVD Process

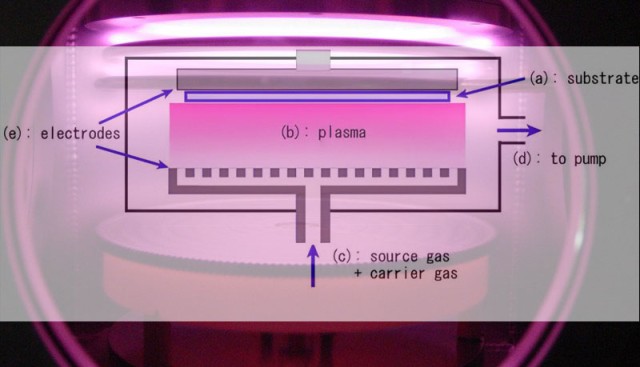

PECVD technology operates under low gas pressure, utilizing low-temperature plasma to generate a glow discharge at the cathode of the process chamber, which is essentially the tray where the sample is placed. This glow discharge, or an alternative heat generator, warms the sample to a predetermined temperature. Subsequently, an appropriate amount of process gases is introduced into the chamber. These gases undergo a series of complex chemical and plasma reactions, ultimately resulting in the formation of a solid film on the surface of the sample.

During the reaction process, the reaction gas enters the furnace cavity from the air inlet and gradually diffuses to the sample surface. Under the influence of the electric field excited by the radio frequency source, the reaction gas decomposes into electrons, ions, and active groups. These decomposition products then undergo chemical reactions to generate the initial components and side reactants that form the film. These products are adsorbed onto the sample surface in the form of chemical bonds, initiating the formation of crystal nuclei for the solid film. The crystal nuclei gradually grow into island-like structures, which continue to coalesce and grow into a continuous film. As the film grows, various by-products gradually detach from the surface and are evacuated from the outlet by the action of the vacuum pump.

The Basic Structure of PECVD Equipment

PECVD equipment is a sophisticated system designed to facilitate the deposition of thin films through plasma-enhanced chemical vapor deposition. This equipment is composed of several critical subsystems, each playing a vital role in the overall process.

Key Components of PECVD Equipment

-

Vacuum and Pressure Control System: This system includes mechanical pumps, molecular pumps, roughing valves, backing valves, gate valves, and vacuum gauges. These components work in tandem to maintain the required vacuum and pressure conditions within the deposition chamber, ensuring that the process occurs under optimal conditions.

-

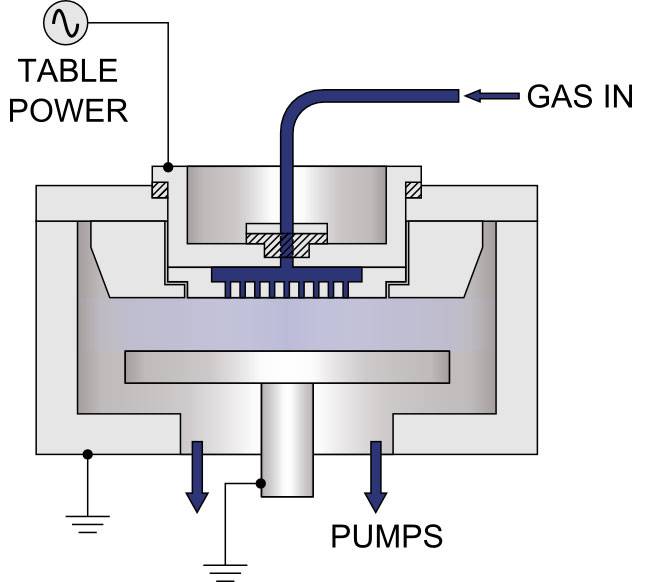

Deposition System: The deposition system is the heart of the PECVD equipment, consisting of a radio frequency (RF) power supply, water cooling system, and substrate heating device. The RF power supply ionizes the reactive gases, while the water cooling system ensures that the equipment remains at the appropriate temperature. The substrate heating device preheats the sample to the necessary temperature, enhancing the adhesion of the deposited film.

-

Gas and Flow Control System: The gas source for the PECVD system typically comes from gas cylinders housed in secure gas cabinets. These gases are carefully controlled and delivered to the process chamber through a network of control panels and pipelines, ensuring precise flow rates and concentrations.

-

System Safety Protection: Safety is paramount in PECVD operations. The system includes various safety mechanisms to protect against hazards such as gas leaks, electrical surges, and overheating. These protections are essential for maintaining a safe working environment and preventing equipment damage.

-

Computer Control: Modern PECVD equipment is often integrated with advanced computer control systems. These systems monitor and regulate various parameters of the deposition process, ensuring consistency and precision. They also provide real-time data and diagnostics, aiding in troubleshooting and optimization.

The block diagram of the PECVD equipment structure, as shown in Figure 2, provides a visual representation of how these components interact to achieve the desired film deposition. Each subsystem is meticulously designed to work harmoniously, ensuring the high-quality and efficient production of thin films.

Vacuum and Pressure Control System

The vacuum and pressure control system is a critical component of PECVD equipment, comprising a variety of mechanical and electronic elements designed to maintain the optimal operating conditions within the process chamber. This system includes mechanical pumps, molecular pumps, roughing valves, pre-stage valves, gate valves, and vacuum gauges. These components work in tandem to ensure that the vacuum levels within the chamber are precisely controlled, typically operating in the range of 10^-2 Torr.

To mitigate the adverse effects of atmospheric gases such as nitrogen, oxygen, and water vapor on the deposition process, the vacuum system employs dry pumps and molecular pumps. These pumps are specifically chosen for their ability to efficiently remove these gases, thereby maintaining a clean and stable environment for the deposition of thin films.

In addition to the basic components, the vacuum and pressure control system may also include advanced features such as vacuum gauge controllers with integrated vacuum gauges, electro-pneumatic vacuum valves, and vacuum air release and leak check valves. These advanced components enhance the system's capability to monitor and control the vacuum levels with greater precision.

For operations requiring inert gas environments, such as those involving Argon, Nitrogen, Helium, or non-flammable forming gas, the system can be configured to maintain a standard positive pressure of 2 PSIG (0.14 Bar). This is achieved through the use of a relief valve and a compound gauge located on the vacuum chamber.

In some advanced setups, additional options like a Flow Adapter Kit for continuous gas flow or a partial pressure control system can be integrated. These options provide enhanced flexibility and control, particularly in applications requiring precise gas mixtures and flow rates.

Overall, the vacuum and pressure control system is essential for ensuring the quality and consistency of the thin films produced by the PECVD process. By maintaining optimal vacuum and pressure conditions, this system significantly contributes to the efficiency and reliability of the entire PECVD equipment.

Precipitation System

The precipitation system is the heart of the PECVD (Plasma Enhanced Chemical Vapor Deposition) process, comprising several critical components such as the RF (Radio Frequency) power supply, water cooling system, and substrate heating device. These elements work in concert to facilitate the deposition of thin films onto substrates.

The RF power supply plays a pivotal role in the system, primarily responsible for ionizing the reaction gases. By applying radio frequency energy, it creates a plasma that initiates the chemical reactions necessary for film formation. This ionization process is crucial as it directly influences the quality and uniformity of the deposited film.

Complementing the RF power supply is the water cooling system, which ensures the efficient operation of various pumps within the PECVD setup. These pumps, including mechanical pumps, Roots pumps, dry pumps, and molecular pumps, are essential for maintaining the vacuum and pressure conditions required for the deposition process. The water cooling system not only regulates the temperature of these pumps but also issues an alarm if the water temperature exceeds the safe operating limits, thereby preventing potential damage to the equipment.

Additionally, the substrate heating device is integral to the precipitation system. It preheats the substrate to a specific temperature, optimizing the conditions for the chemical reactions to occur. This heating step is vital as it can significantly impact the adhesion, structure, and properties of the deposited film.

In summary, the precipitation system is a sophisticated assembly of technologies designed to control and enhance the PECVD process. Each component—the RF power supply, water cooling system, and substrate heating device—contributes uniquely to the overall efficiency and effectiveness of film deposition, making it a cornerstone of PECVD equipment.

Gas and Flow Control System

The gas and flow control system in a PECVD (Plasma-Enhanced Chemical Vapor Deposition) setup is a critical component that ensures the precise delivery of reactive gases to the process chamber. The primary gas sources are typically provided by gas cylinders, which are housed in specialized gas cabinets. These cabinets are equipped with multiple layers of safety protections to mitigate risks associated with gas handling and delivery.

The gases are meticulously controlled and regulated through a series of control panels located on the gas cabinets. These panels manage the flow rates and mix ratios of the gases, ensuring they are delivered to the process chamber in the exact proportions required for the desired film deposition. The gas flow is then channeled through a network of pipes that connect the gas cabinets to the process chamber, ensuring a seamless and uninterrupted supply of gases.

This system is integral to maintaining the consistency and quality of the film deposition process. Any deviation in gas flow or composition can significantly impact the properties of the deposited film, making precise control essential for achieving optimal results. The gas and flow control system, therefore, plays a pivotal role in the overall efficiency and reliability of the PECVD process.

Common Problems and Factors Affecting the Process

Common Equipment Problems and Treatment Measures

Common issues in PECVD equipment can significantly impact the quality and efficiency of the deposition process. These problems often manifest as inability to start the light, glow instability, poor quality of film formation, low sedimentation rate, and reaction chamber pressure instability. Each of these issues can be traced back to specific components of the equipment.

To address these problems, several diagnostic and corrective measures are typically employed:

-

RF Power Supply: A malfunctioning RF power supply can prevent the initiation of the plasma discharge, leading to an inability to start the light. Regular checks and maintenance of the RF power supply are essential to ensure stable operation.

-

Gas Flow Meter: Inaccurate gas flow can result in glow instability and poor film quality. The gas flow meter should be calibrated regularly to maintain precise control over the reaction gases.

-

Cavity Cleanliness: Contaminants in the reaction chamber can degrade the quality of the film and affect the sedimentation rate. Regular cleaning and maintenance of the cavity are crucial to prevent such issues.

-

RF Matching Circuit: Improper matching of the RF circuit can cause instability in the plasma discharge, leading to glow instability and pressure fluctuations. Ensuring that the RF matching circuit is correctly tuned is a key step in maintaining stable operation.

-

Vacuum Conditions: Vacuum leaks or inadequate vacuum conditions can lead to pressure instability and affect the overall process. Regular checks and maintenance of the vacuum system, including pumps and valves, are necessary to maintain optimal conditions.

By systematically addressing these components, operators can effectively troubleshoot and resolve common equipment problems, ensuring a stable and high-quality PECVD process.

Factors Affecting the Process

Several key factors significantly influence the quality and rate of film deposition in the Plasma Enhanced Chemical Vapor Deposition (PECVD) process. These factors include the spacing between the pole plates, the size of the reaction chamber, the operating frequency of the RF power supply, the level of radio frequency power, the gas pressure, and the temperature of the substrate. Each of these parameters plays a crucial role in determining the outcome of the deposition process.

-

Pole Plate Spacing and Reaction Chamber Size: The distance between the pole plates and the dimensions of the reaction chamber can affect the uniformity and density of the plasma. A well-designed chamber ensures that the plasma is evenly distributed, which is essential for consistent film quality.

-

Operating Frequency of RF Power Supply: The frequency at which the RF power supply operates can influence the energy distribution within the plasma. Higher frequencies can lead to more energetic and denser plasmas, which may enhance the deposition rate and film quality.

-

Radio Frequency Power: The amount of RF power applied directly impacts the intensity of the plasma. Higher power levels can accelerate the chemical reactions, leading to faster deposition rates, but may also increase the risk of damaging the substrate or producing non-uniform films.

-

Gas Pressure: The pressure of the gas in the reaction chamber affects the mean free path of the gas molecules. Lower pressures can lead to longer mean free paths, potentially improving the uniformity of the deposition, while higher pressures can enhance the collision rate, which might be beneficial for certain types of films.

-

Substrate Temperature: The temperature of the substrate is critical as it influences the mobility of the deposited atoms. Optimal substrate temperatures can enhance the coalescence of atoms, leading to smoother and denser films. However, excessive temperatures can cause thermal degradation of the substrate or the deposited film.

Understanding and controlling these factors is essential for optimizing the PECVD process, ensuring high-quality film deposition, and achieving the desired properties in the final product.

Conclusion

Summary of PECVD Equipment and Process

The PECVD (Plasma-Enhanced Chemical Vapor Deposition) process is intricate, demanding meticulous control over both the equipment and the process parameters to ensure the quality of the deposited film. Beyond maintaining the stability of the equipment, it is crucial to fully understand the underlying principles of the PECVD process and the myriad factors that influence film quality. This knowledge is indispensable for swiftly diagnosing and addressing any malfunctions that may arise during operation.

Key to this understanding is the grasp of the PECVD equipment's basic structure, which includes the vacuum and pressure control systems, the deposition system, and the gas and flow control system. Each component plays a vital role in the process:

-

Vacuum and Pressure Control Systems: These systems, comprising mechanical pumps, molecular pumps, and various valves, ensure the optimal pressure conditions within the chamber, crucial for the chemical reactions that form the film.

-

Deposition System: This core component includes the radio frequency (RF) power supply, water cooling system, and substrate heating device. The RF power supply ionizes the process gases, while the water cooling system maintains the appropriate temperatures, preventing overheating and ensuring consistent film formation.

-

Gas and Flow Control System: The precise control of gas flow and composition is vital. The gases, typically supplied from cylinders, undergo a series of chemical and plasma reactions, ultimately forming the solid film on the substrate.

In addition to these technical aspects, routine maintenance and repair of the equipment are equally important. Regular checks and upkeep ensure that the equipment operates efficiently, minimizing the risk of unexpected failures and prolonging the lifespan of the machinery. By combining a deep understanding of the PECVD process with diligent equipment maintenance, one can achieve high-quality film deposition and maintain the reliability of the PECVD system.

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Dental Porcelain Sintering Furnace