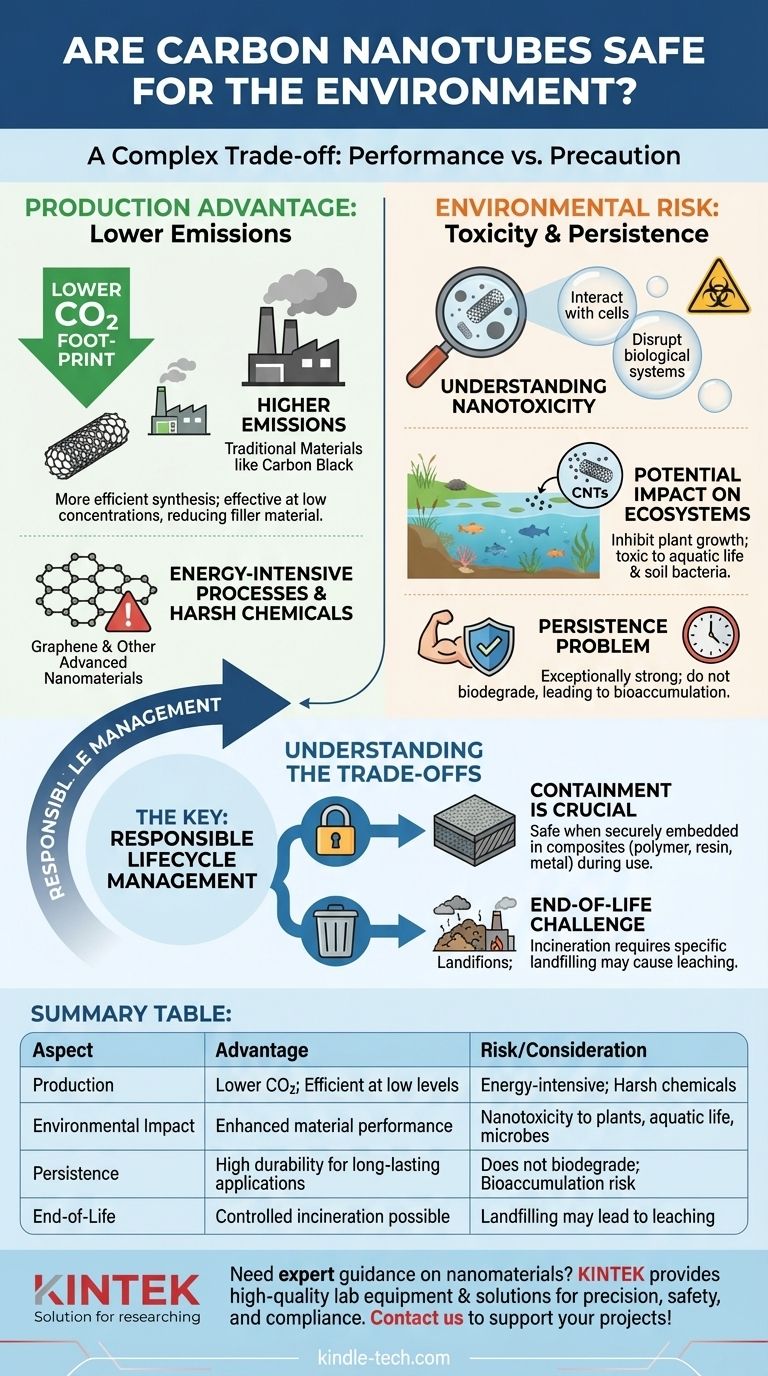

The environmental safety of carbon nanotubes (CNTs) is not a simple yes-or-no question. While their manufacturing process can have a lower carbon footprint compared to alternatives like carbon black, significant concerns exist regarding their potential toxicity and persistence if they are released into the environment. The key to their responsible use lies in understanding and managing their entire lifecycle.

The central issue is a trade-off: Carbon nanotubes offer superior performance and potential production-phase advantages, but this comes with the critical responsibility of preventing their release into ecosystems where their unique nanoscale properties could cause harm.

The Production Advantage: A Look at Emissions

When evaluating any material, its initial production footprint is a critical starting point. In this specific area, CNTs show notable advantages over some conventional alternatives.

Lower CO2 Footprint

The synthesis of carbon nanotubes is often more efficient than that of traditional materials like carbon black. This means producing one kilogram of CNTs can result in lower CO2 emissions.

Furthermore, CNTs are highly effective in composites at much lower concentrations, reducing the total amount of filler material needed and further contributing to a better environmental profile during manufacturing.

Comparison with Graphene

The production of other advanced nanomaterials, such as graphene, also presents environmental challenges. These processes can be energy-intensive, require significant water usage, and often involve harsh chemicals that must be carefully managed.

The Environmental Risk: Toxicity and Persistence

The properties that make CNTs so valuable in materials—their size, shape, and stability—are the same properties that raise concerns about their environmental impact upon release.

Understanding Nanotoxicity

Nanotoxicity refers to the adverse effects of nanomaterials on living organisms. Due to their incredibly small size, CNTs can interact with cells and biological systems in ways that larger particles cannot, potentially disrupting cellular functions in microbes, plants, and animals.

Potential Impact on Ecosystems

If released into soil or water, free carbon nanotubes could have negative consequences. Research has shown they can inhibit the growth of certain plants and be toxic to aquatic organisms and essential bacteria in the soil.

The Persistence Problem

Carbon nanotubes are exceptionally strong and durable. This is a major benefit for material science but a significant drawback for environmental safety. They do not biodegrade easily and can persist in the environment for long periods, leading to potential bioaccumulation.

Understanding the Trade-offs: Performance vs. Precaution

The decision to use CNTs requires balancing their undeniable performance benefits against the need for responsible environmental stewardship. The primary risk is not from their use, but from their potential escape.

The Benefit of Containment

The safest way to use CNTs is to ensure they are securely embedded within a larger material matrix, such as a polymer, resin, or metal. When locked in place, they cannot become airborne or leach into the environment, effectively neutralizing the toxicity risk during the product's useful life.

The End-of-Life Challenge

The greatest risk of environmental release occurs at the end of a product's life. Disposing of CNT-enabled composites requires careful consideration. Incineration can destroy the CNTs but may require specific conditions, while landfilling raises concerns about their potential to leach into soil and groundwater over time.

Making the Right Choice for Your Goal

Evaluating carbon nanotubes requires looking beyond a single metric and considering your primary objective and risk tolerance.

- If your primary focus is reducing manufacturing CO2 and maximizing material performance: CNTs are an excellent choice, provided you can guarantee they remain locked within a stable composite matrix throughout the product's lifecycle.

- If your primary focus is minimizing potential ecotoxicity risk above all else: You may need to consider traditional fillers, accepting their lower performance, or ensure your end-of-life plan (e.g., controlled recycling or incineration) is robust.

- If your primary focus is a holistic environmental assessment: You must conduct a full lifecycle analysis that weighs the production benefits against the potential risks of disposal and environmental release.

Ultimately, the responsible use of carbon nanotubes depends on a clear understanding of both their remarkable potential and their environmental risks.

Summary Table:

| Aspect | Advantage | Risk/Consideration |

|---|---|---|

| Production | Lower CO2 emissions than carbon black; effective at low concentrations | Energy-intensive processes; use of harsh chemicals |

| Environmental Impact | Enhanced material performance when contained | Potential nanotoxicity to plants, aquatic life, and soil microbes |

| Persistence | High durability for long-lasting applications | Does not biodegrade easily; risk of bioaccumulation |

| End-of-Life | Can be destroyed via controlled incineration | Landfilling may lead to leaching into soil and groundwater |

Need expert guidance on selecting and safely handling nanomaterials like carbon nanotubes for your laboratory? KINTEK specializes in providing high-quality lab equipment and consumables tailored to your research needs. Whether you're developing advanced composites or conducting environmental impact studies, our solutions ensure precision, safety, and compliance. Contact us today to learn how we can support your innovative projects with reliable products and expert advice!

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- Why do we need optical coating? To Control Light and Enhance Optical Performance

- What is the process of thin film optical coating? Precision Light Control for Lenses & Mirrors

- Which of the following are properties of carbon nanotubes? Unlock Their Unique Electrical, Thermal & Mechanical Strengths

- What is thin film in wave optics? Harness Light Interference for Precision Optical Design

- What is sputtering inorganic materials? Achieve Superior Thin Film Deposition Quality

- What is the concept of thin film? Unlocking Unique Properties at the Nanoscale

- What are the properties of Gold (Au) relevant to its use in coatings? High-Performance Stability & Conductivity

- What are the characteristics of a coating produced by low-temperature arc vapor deposition (LTAVD)? Key Performance Insights