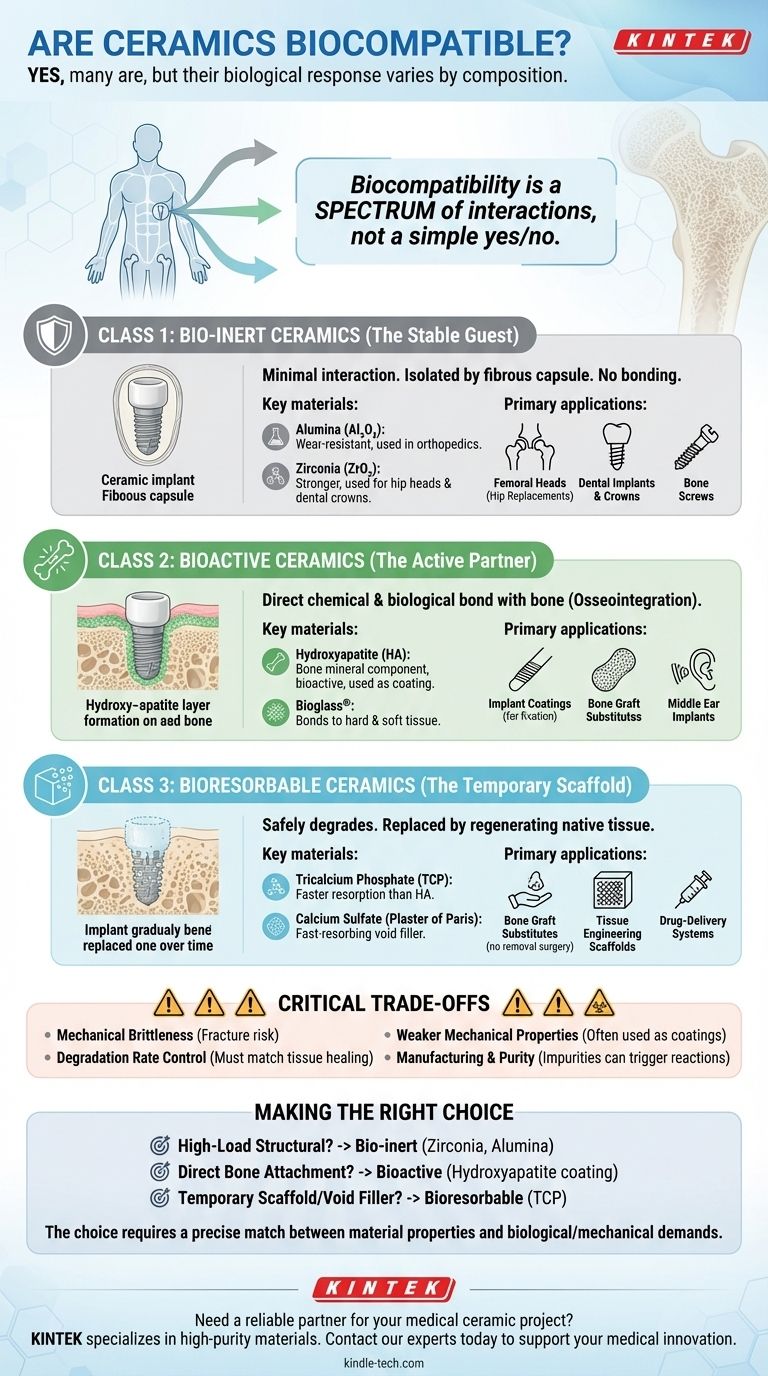

Yes, many ceramics are biocompatible, but their behavior within the body varies dramatically depending on their chemical composition. They are not a single class of material but a diverse group with distinct biological responses, making the choice of ceramic entirely dependent on the specific medical application.

The crucial takeaway is that "biocompatibility" for ceramics is not a simple yes-or-no property. It describes a spectrum of interactions, ranging from being completely ignored by the body (bio-inert), actively bonding with bone (bioactive), or safely dissolving to be replaced by new tissue (bioresorbable).

The Three Classes of Bioceramics

To understand their use, we must classify bioceramics not by what they are, but by what they do inside the body. This interaction defines their function and their suitability for a given medical device.

Class 1: Bio-inert Ceramics (The Stable Guest)

Bio-inert ceramics are designed to have minimal interaction with the surrounding biological tissue. Once implanted, the body forms a thin, fibrous capsule around them, effectively isolating the material.

They do not chemically bond with bone or release substances into the body. Their value lies in their exceptional chemical stability, hardness, and wear resistance.

Key Materials:

- Alumina (Al₂O₃): A very hard, dense ceramic with excellent wear resistance, commonly used for over four decades in orthopedics.

- Zirconia (ZrO₂): Even stronger and more fracture-resistant than alumina, making it the material of choice for modern hip implant heads and durable dental crowns.

Primary Applications:

- Femoral heads for hip replacements.

- Dental implants and crowns.

- Bone screws.

Class 2: Bioactive Ceramics (The Active Partner)

Bioactive ceramics form a direct chemical and biological bond with bone tissue. When implanted, they develop a hydroxyapatite layer on their surface that is chemically similar to the mineral phase of bone, encouraging bone cells to attach and grow.

This ability to integrate with the host tissue, a process called osseointegration, is their defining characteristic.

Key Materials:

- Hydroxyapatite (HA): The primary mineral component of natural bone, making it exceptionally bioactive. It is often used as a coating on metallic implants.

- Bioglass®: A specific composition of silica-based glass that is highly bioactive, bonding to both hard and soft tissue.

Primary Applications:

- Coatings on joint replacement stems to promote fixation.

- Bone graft substitutes and void fillers.

- Middle ear implants.

Class 3: Bioresorbable Ceramics (The Temporary Scaffold)

Bioresorbable (or biodegradable) ceramics are designed to degrade safely over time. The body's natural metabolic processes gradually dissolve the implant, and the material is replaced by regenerating native tissue.

The key design challenge is to match the degradation rate of the ceramic with the healing rate of the tissue it is supporting.

Key Materials:

- Tricalcium Phosphate (TCP): A type of calcium phosphate that resorbs more quickly than hydroxyapatite.

- Calcium Sulfate (Plaster of Paris): A fast-resorbing material used as a bone void filler.

Primary Applications:

- Bone graft substitutes that don't require a second removal surgery.

- Scaffolds for tissue engineering.

- Drug-delivery systems.

Understanding the Critical Trade-offs

Choosing a bioceramic involves balancing its biological benefits against its physical limitations. No single material is perfect for every situation.

Mechanical Brittleness

Bio-inert ceramics like alumina and zirconia are extremely strong under compression but are brittle. Unlike metals, they cannot deform under stress and are susceptible to catastrophic fracture from a sharp impact or an existing microscopic flaw.

Degradation Rate Control

For bioresorbable ceramics, the degradation rate is paramount. If the material dissolves too quickly, the implant loses its structural integrity before the new tissue is strong enough. If it dissolves too slowly, it can impede full tissue regeneration.

Weaker Mechanical Properties

Bioactive and bioresorbable ceramics generally do not possess the high mechanical strength of bio-inert ceramics. This is why hydroxyapatite is most often used as a coating on a strong metal core rather than as a load-bearing implant itself.

Manufacturing and Purity

The biocompatibility of any ceramic is highly dependent on its purity and processing. Trace impurities or incorrect phase composition can trigger an adverse immune response, turning a theoretically biocompatible material into a problematic one.

Making the Right Choice for Your Application

The selection of a bioceramic must be driven by the end goal—the specific problem you are trying to solve within the body.

- If your primary focus is a high-load, high-wear structural component: Bio-inert ceramics like zirconia and alumina are the established standard due to their strength and stability.

- If your primary focus is encouraging direct bone attachment and integration: A bioactive ceramic like hydroxyapatite, often as a coating on a metallic implant, is the ideal choice.

- If your primary focus is to fill a void and provide a temporary scaffold for new bone growth: A bioresorbable ceramic like tricalcium phosphate is the correct approach.

Ultimately, choosing the right ceramic requires a precise match between the material's properties and the specific biological and mechanical demands of its intended environment.

Summary Table:

| Class of Bioceramic | Key Interaction | Example Materials | Primary Applications |

|---|---|---|---|

| Bio-inert | Minimal interaction; fibrous encapsulation | Alumina (Al₂O₃), Zirconia (ZrO₂) | Hip replacement heads, dental crowns, bone screws |

| Bioactive | Direct chemical bond with bone (osseointegration) | Hydroxyapatite (HA), Bioglass® | Implant coatings, bone graft substitutes |

| Bioresorbable | Safely degrades and is replaced by new tissue | Tricalcium Phosphate (TCP), Calcium Sulfate | Bone void fillers, tissue engineering scaffolds |

Need a reliable partner for your medical ceramic project? Selecting the right bioceramic is critical for your device's success. KINTEK specializes in high-purity materials and components for medical and laboratory applications. Our expertise can help you navigate material selection, purity requirements, and manufacturing challenges to ensure your implant meets the highest standards of biocompatibility and performance.

Contact our experts today to discuss how we can support your medical innovation.

Visual Guide

Related Products

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- Why is Boron Nitride used in RRDE? Enhance Precision with Superior Insulating and Protective Material

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- Why is Boron Nitride utilized as a coating for graphite molds? Protect Your Mo-Na Powder During Sintering