While a powerful joining method, brazing presents four notable disadvantages that require careful consideration during design and manufacturing. Its primary limitations stem from the need for tight joint clearances for capillary action, the risk of heat damage to the base materials, the challenges of joining dissimilar materials due to thermal expansion, and the necessity for meticulous pre-cleaning and joint design.

The core challenge of brazing lies in its sensitivity. Its reliance on high heat and capillary action imposes strict constraints on joint design, material selection, and preparation that are not present in many other joining techniques.

The Requirement for Precise Joint Design

Brazing is not a process for filling large or inconsistent gaps. Its success is fundamentally tied to the precise engineering of the joint before the heating process ever begins.

The Constraint of Capillary Action

A brazed joint is formed when molten filler metal is drawn into the tight space between two components through capillary action. This physical phenomenon is the same force that pulls water up a narrow tube.

For this to work, the gap between the parts, known as the joint clearance, must be extremely consistent and small.

Strict Clearance Control

If the gap is too wide, capillary force is too weak to draw the filler metal through the entire joint, resulting in voids and a weak bond. If the gap is too narrow, the filler metal cannot flow in at all.

This necessitates high-precision machining and preparation of the components, which can significantly increase manufacturing costs compared to methods like welding that can accommodate less precise fit-ups.

Pre-Placing Filler Metal

Unlike welding where filler is added during the process, brazing typically requires the filler metal (often as a wire, ring, or paste) to be placed at the joint before heating. The part must be designed to accommodate this preform and ensure it is positioned correctly to flow into the joint when it melts.

The Impact of High Process Temperatures

The temperatures required to melt brazing filler metal (often above 450°C / 842°F) are high enough to permanently alter the properties of the base materials being joined.

Risk of Annealing and Weakening

Many metals, like hardened steels or work-hardened aluminum, derive their strength from specific heat treatments or mechanical processing. The heat of the brazing cycle can undo this work, annealing the material and causing it to soften and lose strength.

This is a critical consideration, as the finished assembly may not meet its required mechanical performance specifications even if the brazed joint itself is sound.

Challenges with Dissimilar Materials

When joining two different materials (such as a ceramic to a metal), a significant problem arises from their different rates of thermal expansion. As the assembly is heated to brazing temperature and then cooled, one material will expand and shrink more than the other.

This differential movement creates immense internal stress at the joint, which can cause the more brittle material to crack or the joint to fail upon cooling.

Understanding the Trade-offs

Choosing brazing means accepting a specific set of limitations in exchange for its benefits, such as clean joints and the ability to join thin sections.

Lower Strength Than Welded Joints

While a well-designed brazed joint can be stronger than the filler metal itself, it is generally weaker than the parent materials. A welded joint, by contrast, fuses the parent materials together, creating a continuous metallurgical bond that can often match the original material's strength.

The Need for Meticulous Cleaning

Capillary action and metallurgical bonding can only occur on perfectly clean surfaces. Any surface contaminants—such as oils, grease, or even natural oxide layers—will prevent the filler metal from "wetting" the surfaces and flowing into the joint.

This requires a rigorous, often multi-stage, cleaning process before assembly, adding time and complexity to the manufacturing workflow.

Corrosive Flux Residues

Many brazing processes, especially for materials like aluminum, require a chemical flux to break down surface oxides and allow the filler to bond. These flux agents are often highly corrosive.

If any flux residue is trapped in the joint or not completely cleaned off after brazing, it can lead to corrosion and premature failure of the assembly over time. This necessitates an additional, thorough post-brazing cleaning step.

Making the Right Choice for Your Goal

To determine if brazing is appropriate, you must weigh its disadvantages against the specific requirements of your application.

- If your primary focus is maximum joint strength: Consider welding, as it fuses the parent metals directly and typically creates a stronger, more monolithic joint.

- If you are joining heat-sensitive or pre-hardened components: Carefully evaluate if the brazing temperature will unacceptably soften or damage your materials; a lower-temperature process like soldering or an adhesive may be better.

- If you require joining dissimilar materials with high precision: Brazing can be an excellent choice, but you must carefully engineer the joint to accommodate stresses from thermal expansion.

- If your design involves loose tolerances or large gaps: Brazing is unsuitable; welding or mechanical fasteners are better equipped to handle these conditions.

Understanding these inherent limitations is the first step toward leveraging brazing effectively for the applications where it truly excels.

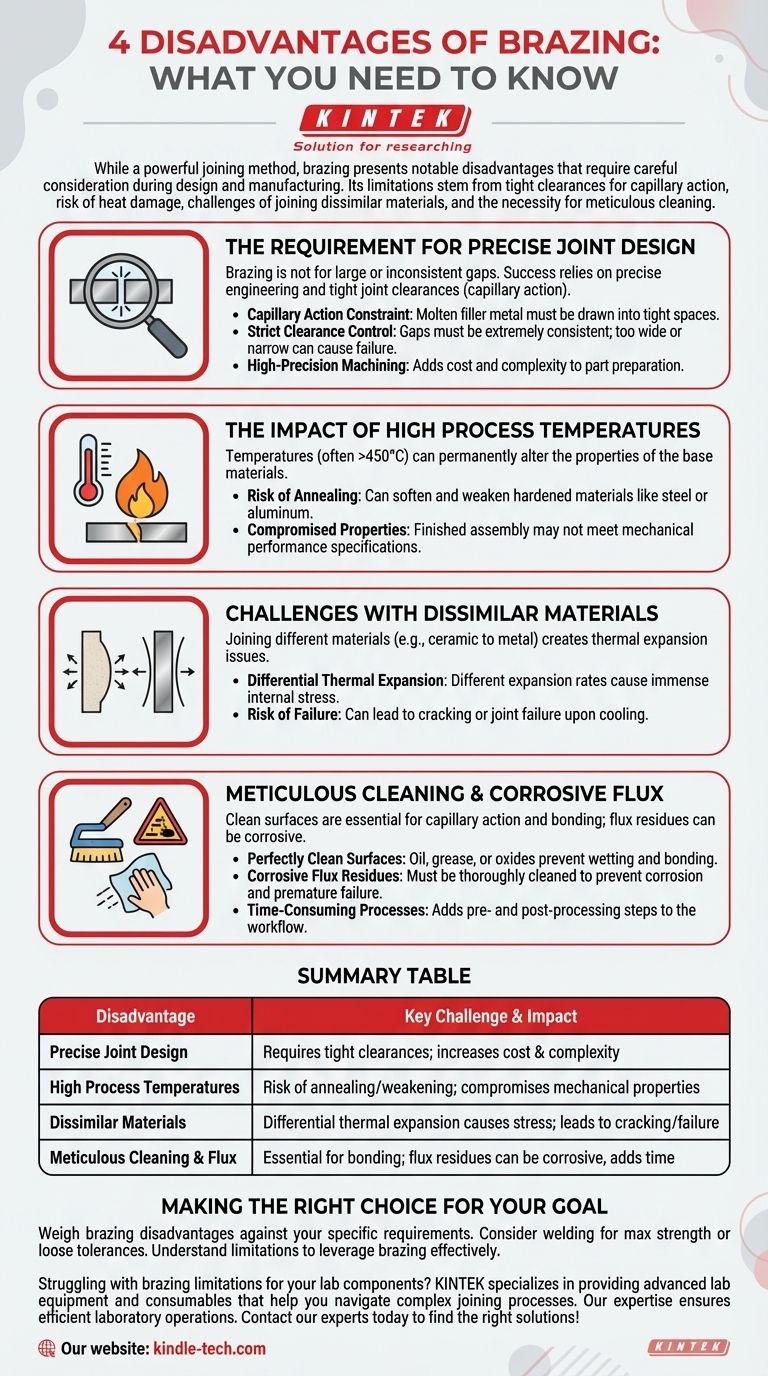

Summary Table:

| Disadvantage | Key Challenge | Impact on Manufacturing |

|---|---|---|

| Precise Joint Design | Requires tight, consistent clearances for capillary action | Increases cost and complexity of part preparation |

| High Process Temperatures | Risk of annealing and weakening base materials | Can compromise the final assembly's mechanical properties |

| Dissimilar Materials | Differential thermal expansion causes stress | May lead to cracking or joint failure upon cooling |

| Meticulous Cleaning & Flux | Essential for proper bonding; flux residues can be corrosive | Adds time-consuming pre- and post-processing steps |

Struggling with brazing limitations for your lab components? KINTEK specializes in providing advanced lab equipment and consumables that help you navigate complex joining processes. Our expertise ensures your laboratory operations are efficient and your materials are handled with precision. Contact our experts today to find the right solutions for your specific laboratory needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Lab-Scale Vacuum Induction Melting Furnace

- Boron Nitride (BN) Ceramic Plate

- Thermally Evaporated Tungsten Wire for High Temperature Applications

People Also Ask

- What is the most important part in preheating before welding? Master Cooling Rate Control for Stronger Welds

- What environmental conditions does a vacuum carbon tube furnace provide? Optimize YAG Ceramic Sintering

- What is the primary function of a high-temperature furnace in thermal stability testing? Ensure Inhibitor Performance

- What is a high temperature furnace used for? A Guide to Material Transformation

- Can stainless steel be annealed? Discover the Key to Restoring Corrosion Resistance

- Where is vacuum furnace used? Essential for Aerospace, Medical, and High-Tech Manufacturing

- What is the operating temperature of a batch type furnace? From 200°C to 3000°C for Your Specific Process

- How does argon and nitrogen cooling compare in vacuum furnaces? A Guide to Faster, Cheaper Quenching