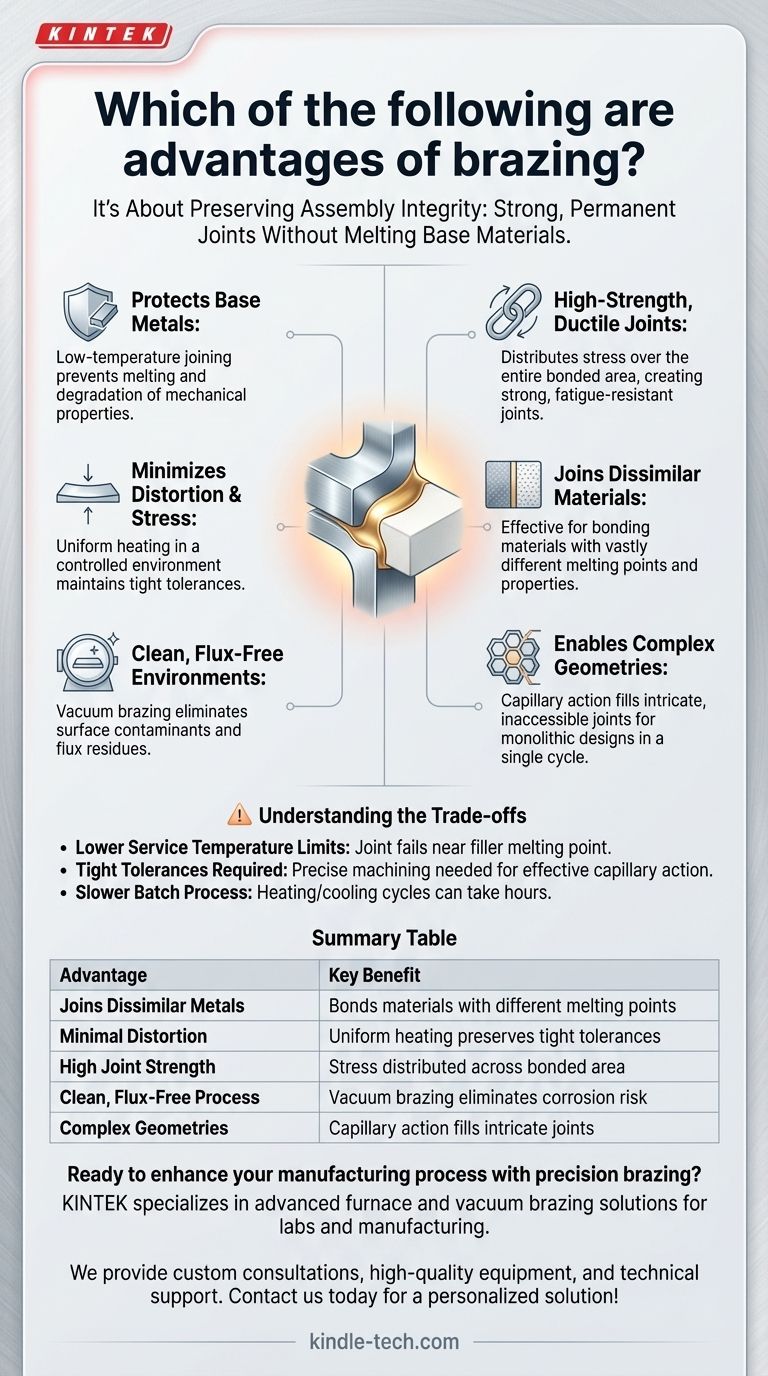

Fundamentally, the advantages of brazing stem from its ability to create strong, permanent joints without melting or damaging the base materials being joined. Key benefits include the ability to join dissimilar metals, achieve joint strengths that can exceed the parent materials, and manufacture complex assemblies with minimal distortion. The process, particularly furnace and vacuum brazing, also produces exceptionally clean parts that often require no post-processing.

Brazing is not merely a method for joining parts; it's a manufacturing process that preserves the integrity of the base materials while creating exceptionally strong, clean, and complex assemblies. It excels where precision, material diversity, and minimal thermal stress are more critical than raw joining speed.

Why Choose Brazing? It's About Preserving Assembly Integrity

While welding fuses metals together by melting them, brazing works more like a high-strength solder. A filler metal with a lower melting point is drawn into a tight-fitting joint by capillary action and forms a metallurgical bond. This core difference is the source of its primary advantages.

Low-Temperature Joining Protects Base Metals

The brazing process occurs at a temperature below the melting point of the components you are joining.

This is a critical distinction. Because the base metals do not melt, their fundamental mechanical and physical properties remain largely unaffected, preventing the degradation that can occur in the heat-affected zone of a weld.

Uniform Heating Minimizes Distortion and Stress

Methods like furnace and vacuum brazing heat the entire assembly in a highly controlled environment.

This uniform heating and slow, controlled cooling cycle drastically reduces thermal stress and distortion (warping). This makes brazing the ideal choice for high-precision components where maintaining tight tolerances is non-negotiable.

Clean, Flux-Free Environments

Modern brazing, especially in a vacuum furnace, creates an exceptionally clean environment.

This process removes surface contaminants like oxides, resulting in a bright, clean finish right out of the furnace. More importantly, it eliminates the need for chemical fluxes, which avoids the risk of flux inclusions that can cause corrosion or joint failure over time.

The Unique Capabilities of Brazing

Beyond preserving material integrity, brazing unlocks manufacturing possibilities that are difficult or impossible to achieve with other methods.

Creating High-Strength, Ductile Joints

When properly designed, a brazed joint distributes stress over the entire bonded surface area, rather than concentrating it at a single point.

This often results in a final joint that is stronger and more resistant to fatigue and vibration than the individual base metals themselves.

Joining Dissimilar Materials

Brazing is one of the most effective methods for creating strong, permanent bonds between completely different types of materials.

Because it doesn't rely on melting the base metals, you can easily join materials with vastly different melting points, such as steel to copper, ceramics to metal, or tungsten carbide to steel.

Enabling Complex Geometries

The capillary action of the brazing filler metal allows it to flow into long, narrow, and inaccessible joints.

This makes it possible to design and manufacture highly complex assemblies, such as intricate honeycomb structures or components with internal channels, by brazing multiple simple parts into one robust, monolithic structure. This can be done for multiple joints and multiple assemblies simultaneously in a single furnace cycle.

Understanding the Trade-offs

No process is perfect. To make an informed decision, you must recognize brazing's limitations.

Lower Service Temperature Limits

A brazed joint's primary weakness is heat. The component cannot be used in an environment where temperatures approach the melting point of the filler alloy, as the joint will fail. Welded joints typically have much higher service temperature limits.

Requirement for Tight Tolerances

Capillary action, the force that draws the filler metal into the joint, only works effectively with a very small, consistent gap between the parts (typically 0.001" to 0.005"). This requires precise machining of the components before brazing, which can add to the overall cost.

Slower Process and Batch Dependency

While you can braze many parts at once, the heating and cooling cycles in a furnace can take several hours. This makes brazing less suitable than welding for rapid, one-off repairs or single-unit production.

Making the Right Choice for Your Goal

Your decision to use brazing should be driven by the specific requirements of your project.

- If your primary focus is joining dissimilar materials: Brazing is the superior and often the only viable choice for creating a strong, permanent bond.

- If your primary focus is creating high-precision, distortion-free assemblies: Furnace or vacuum brazing's uniform heating provides unmatched dimensional stability.

- If your primary focus is manufacturing complex components with multiple or inaccessible joints: Brazing allows you to build intricate designs in a single, efficient operation.

- If your primary focus is maximum joint strength at high service temperatures: A properly designed weld on compatible materials will likely be a better choice.

Ultimately, selecting brazing is a strategic decision to prioritize the quality, precision, and integrity of the final assembly.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Joins Dissimilar Metals | Bonds materials with different melting points (e.g., steel to ceramic) |

| Minimal Distortion | Uniform heating preserves tight tolerances and prevents warping |

| High Joint Strength | Stress is distributed across the entire bonded area |

| Clean, Flux-Free Process | Vacuum brazing eliminates corrosion risk from flux residues |

| Complex Geometries | Capillary action fills intricate, hard-to-reach joints |

Ready to enhance your manufacturing process with precision brazing?

At KINTEK, we specialize in advanced brazing solutions for laboratories and manufacturing facilities. Our expertise in furnace and vacuum brazing ensures your assemblies achieve maximum strength, cleanliness, and dimensional accuracy—whether you're joining dissimilar materials or creating complex components.

We provide:

- Custom brazing consultations for your specific material challenges

- High-quality lab equipment and consumables tailored to brazing applications

- Technical support to optimize joint design and process parameters

Contact us today to discuss how our brazing expertise can improve your product integrity and manufacturing efficiency. Get in touch with our experts for a personalized solution!

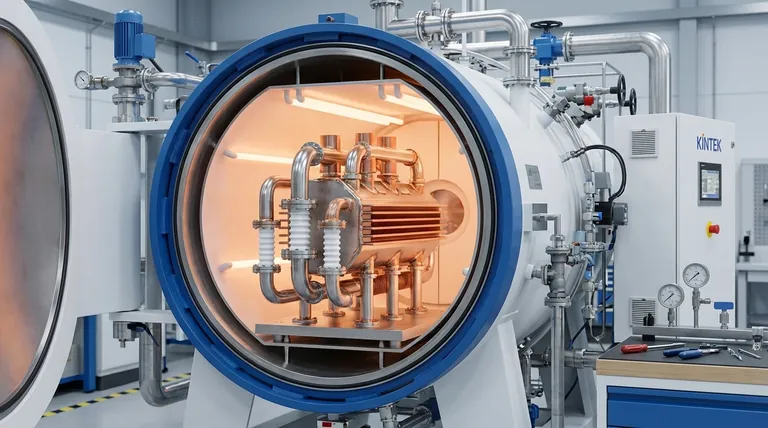

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Boron Nitride (BN) Ceramic Plate

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What are the different types of brazing welding? A Guide to Choosing the Right Heat Source