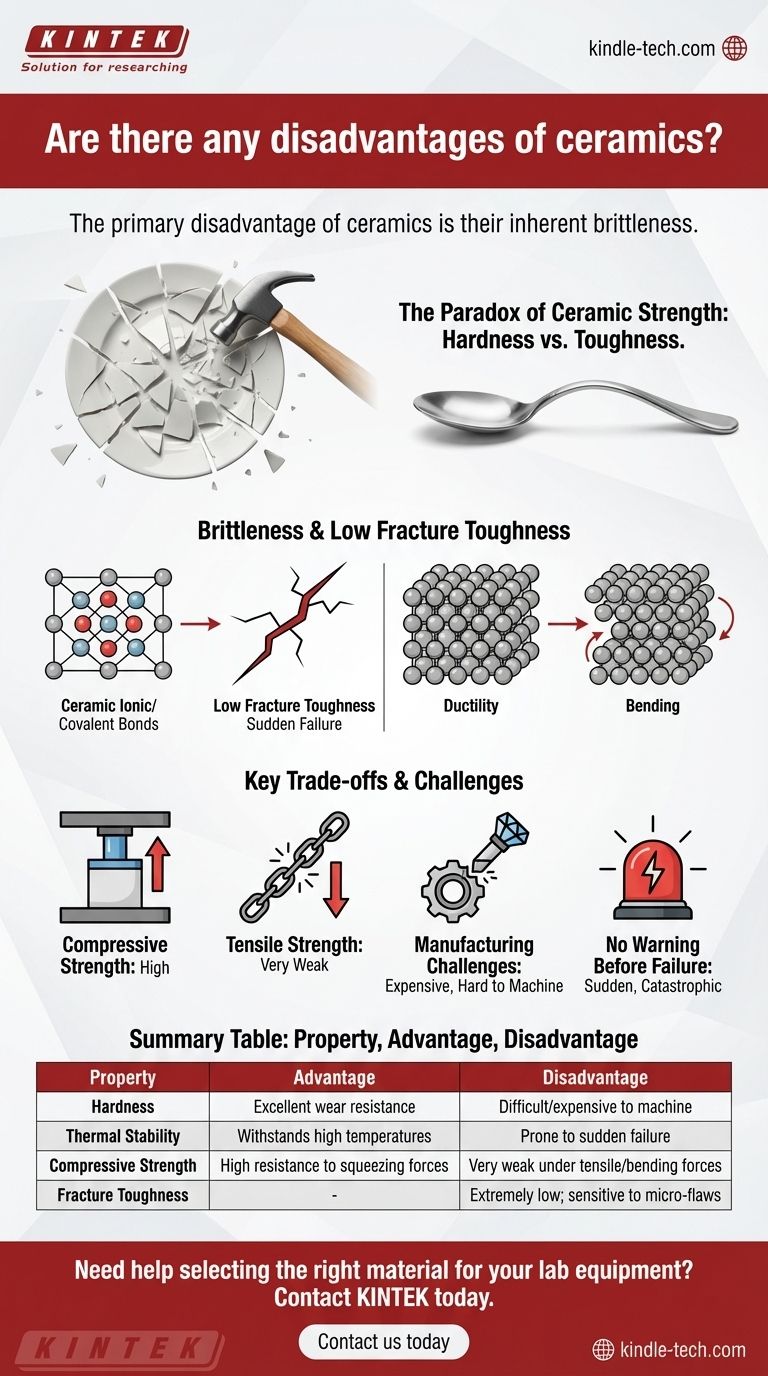

The primary disadvantage of ceramics is their inherent brittleness. While exceptionally hard and resistant to heat and wear, most ceramic materials have very low fracture toughness. This means that instead of bending or deforming under stress like a metal, they are prone to sudden, catastrophic failure when subjected to sharp impacts or tensile forces.

The core challenge with ceramics lies in a fundamental trade-off: their incredible hardness and stability come at the direct cost of toughness. Understanding this balance between compressive strength and brittleness is essential for their proper application.

The Paradox of Ceramic Strength: Hardness vs. Toughness

The very properties that make ceramics desirable—their rigidity and stability—are also the source of their main limitation. This is not a contradiction, but a direct consequence of their atomic structure.

Defining Brittleness

Brittleness is the tendency of a material to fracture with little to no detectable plastic deformation beforehand. When a ceramic part fails, it fails completely and suddenly.

Think of dropping a steel spoon versus a ceramic plate. The spoon might dent, a form of plastic deformation, but the plate shatters. This shattering is a classic example of brittle failure.

The Role of Microstructure

Ceramics are typically characterized by very strong ionic and covalent bonds holding their atoms in a rigid crystalline lattice. This structure is excellent at resisting compression and high temperatures.

However, these strong, fixed bonds prevent atoms from sliding past one another, a mechanism known as "dislocation slip." In metals, this slip is what allows the material to bend and deform. Without it, ceramics have no way to relieve stress other than by breaking these bonds, which results in a crack.

Low Fracture Toughness Explained

Fracture toughness is a measure of a material's ability to resist the propagation of a crack. Ceramics have notoriously low fracture toughness.

This means that once a microscopic crack forms, it requires very little energy to spread rapidly through the material, leading to complete failure.

Sensitivity to Pre-existing Flaws

The practical consequence of low fracture toughness is an extreme sensitivity to tiny, often invisible flaws. Microscopic pores, grain boundaries, or even minute surface scratches from manufacturing or handling can act as stress concentrators.

Under an applied load, the stress at the tip of one of these tiny flaws can be many times greater than the overall stress on the part, providing the starting point for a catastrophic crack.

Understanding the Key Trade-offs

Choosing to use a ceramic material requires acknowledging a specific set of engineering compromises. Ignoring these can lead to component failure.

Compressive Strength vs. Tensile Strength

Ceramics exhibit immense compressive strength—they can withstand enormous squeezing forces. This is why they are used for things like brake pads and building materials (bricks).

However, they are very weak under tensile strength (pulling forces) or bending, as these forces work to pull apart the atomic bonds and open up micro-cracks. Engineering designs must ensure ceramic parts are primarily loaded in compression.

Manufacturing and Machining Challenges

The extreme hardness of ceramics makes them very difficult and expensive to machine into complex shapes after they are fired.

Most shaping must be done before the final high-temperature sintering process. Any finishing or grinding after firing requires specialized and costly diamond-tipped tools, significantly increasing production costs compared to metals or polymers.

The Lack of "Warning" Before Failure

A critical disadvantage in many applications is that ceramics provide no warning before they break. A metal component will often stretch, bend, or warp, signaling that it is overloaded.

Ceramics do not provide this ductile "grace period." They fail suddenly and completely, which is unacceptable in applications where such a failure could endanger safety.

Making the Right Choice for Your Application

Your decision to use a ceramic should be based on a clear understanding of whether its strengths align with your primary goal and whether you can design around its weaknesses.

- If your primary focus is extreme hardness, wear resistance, or high-temperature stability: Ceramics are an excellent choice, but you must design the component to exist in a state of compression and protect it from impacts.

- If your primary focus is structural integrity under variable loads or impact resistance: A metal alloy or a fiber-reinforced composite material is almost always a better choice due to their superior toughness and ductility.

- If your primary focus is creating complex shapes at a low cost: Polymers or castable metals are far more suitable, as the cost and difficulty of machining ceramics can be prohibitive.

Understanding the fundamental trade-off between hardness and brittleness is the key to successfully leveraging the unique advantages of ceramic materials.

Summary Table:

| Property | Advantage | Disadvantage |

|---|---|---|

| Hardness | Excellent wear resistance | Difficult and expensive to machine |

| Thermal Stability | Withstands high temperatures | Prone to sudden, catastrophic failure |

| Compressive Strength | High resistance to squeezing forces | Very weak under tensile or bending forces |

| Fracture Toughness | - | Extremely low; sensitive to micro-flaws |

Need help selecting the right material for your lab equipment? At KINTEK, we specialize in providing lab equipment and consumables tailored to your specific needs. Whether you require the high-temperature stability of ceramics or the toughness of metals, our experts can guide you to the optimal solution. Contact us today to enhance your lab's performance and safety!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Rod Insulated for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

People Also Ask

- What is the temperature of alumina sintering? A Guide to Achieving Optimal Ceramic Density

- What is the process of making silicon carbide? From Raw Materials to Advanced Ceramics

- How do alumina ceramic tubes address technical challenges in electrochemical devices? Ensure Peak Signal Integrity.

- What is special about ceramic? Unmatched Durability Against Heat, Wear, and Chemicals

- What metrics were used to evaluate the grinding process of the composite ceramic (AlSiTi)? Optimize Your Grinding Result

- What role does polyurethane foam play as a sacrificial template? Create Advanced Porous MgO Ceramics

- What is the density of ceramic properties? A Guide to Material Selection for High-Performance Applications

- Are ceramics chemically unreactive? Discover Their Remarkable Corrosion Resistance