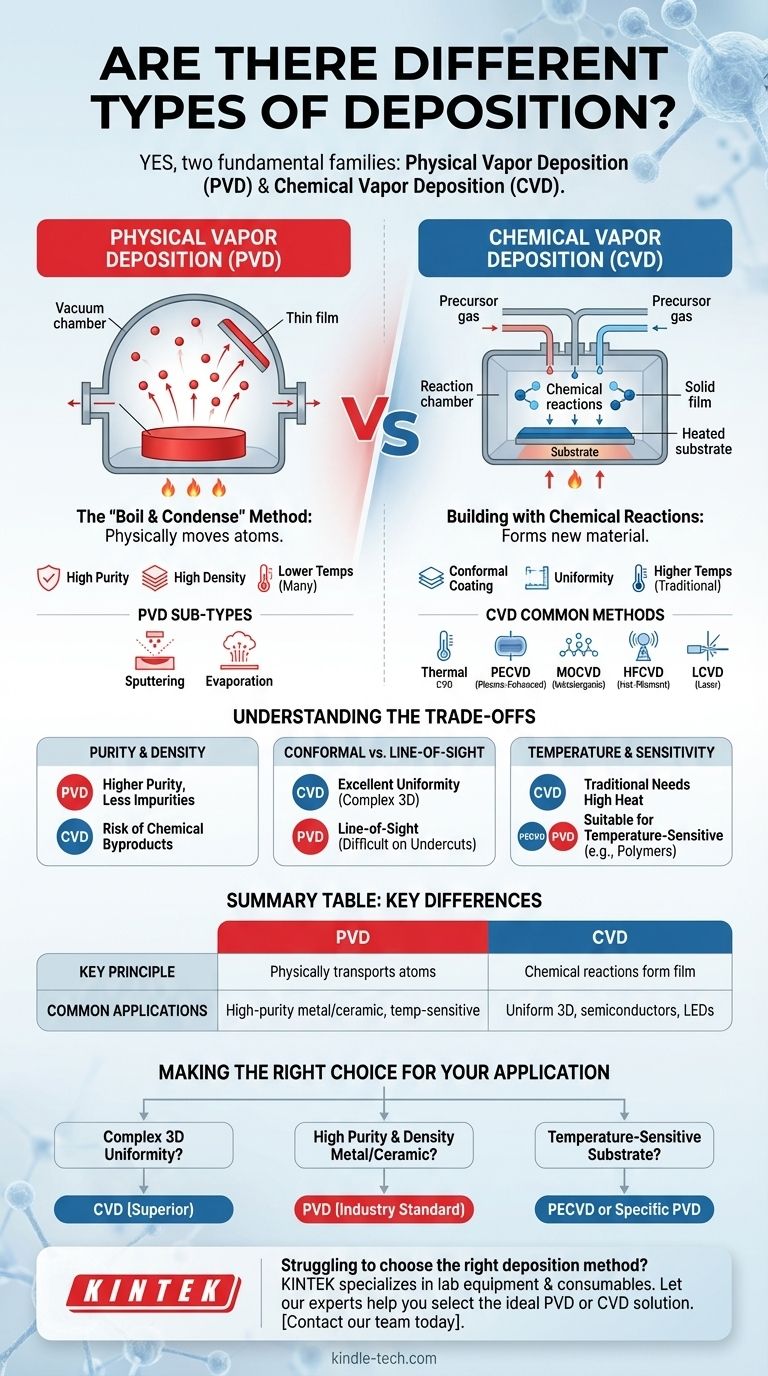

Yes, there are several methods for deposition, which are primarily categorized into two fundamental families: Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). These techniques are the cornerstone of modern materials science and manufacturing, used to apply ultra-thin functional films onto a surface, known as a substrate. The method chosen dictates the properties, quality, and cost of the final product.

The fundamental difference between deposition types lies in how the source material is transported to the target surface. Physical Vapor Deposition (PVD) physically moves atoms, while Chemical Vapor Deposition (CVD) uses chemical reactions to form and deposit a new material. Your choice depends entirely on the material's properties and the specific requirements of the final film.

The Two Pillars of Deposition: PVD vs. CVD

At the highest level, all deposition processes fall into one of two categories. Understanding this distinction is the first step to navigating the field.

Physical Vapor Deposition (PVD): The "Boil and Condense" Method

PVD is a process that takes a solid or liquid source material and transforms it into a vapor. This vapor then travels through a vacuum or low-pressure environment and condenses on the substrate as a thin film.

This method is analogous to boiling water and watching steam condense on a cool surface. PVD is typically used for materials with high melting points, such as metals and ceramics, that are difficult to work with chemically.

Chemical Vapor Deposition (CVD): Building with Chemical Reactions

CVD does not simply move existing material. Instead, it introduces one or more volatile precursor gases into a reaction chamber. These gases react and decompose on or near the substrate's surface, forming a new solid material that deposits as a film.

This process is fundamentally about creating a new material directly on the target surface through a controlled chemical reaction. It's often suitable when precursor materials have relatively low melting and boiling points.

Exploring the Sub-Types of Deposition

Within the two main families of PVD and CVD, numerous specific techniques have been developed to handle different materials and achieve specific film properties.

Common CVD Methods

The "flavor" of CVD is determined by how the chemical reaction is initiated and sustained.

- Thermal CVD: Uses high heat to provide the energy needed to break chemical bonds and drive the reaction on the substrate.

- Plasma-Enhanced CVD (PECVD): Uses an electric field to create a plasma (an ionized gas), which provides the energy for the reaction. This allows deposition to occur at much lower temperatures than thermal CVD.

- Metalorganic CVD (MOCVD): Uses precursor gases that contain both metal and organic components. This is a highly precise method critical for manufacturing advanced semiconductors and LEDs.

- Hot-Filament CVD (HFCVD): Uses a heated wire or filament to thermally decompose the precursor gases, a technique commonly used for creating synthetic diamond films.

- Laser CVD (LCVD): Uses a focused laser beam to heat a very small area on the substrate, causing the chemical reaction to occur only in that specific spot.

Understanding the Trade-offs

Neither PVD nor CVD is universally superior; they represent a series of engineering trade-offs. The right choice depends entirely on the goal.

Purity and Density

PVD processes can often produce films with higher purity and density. Because the source material is physically transported, there is less risk of incorporating impurities from chemical byproducts that can occur in CVD.

Conformal Coating vs. Line-of-Sight

CVD is exceptional at producing conformal coatings, meaning the film's thickness is uniform across a complex, three-dimensional surface. The precursor gases can flow around and into intricate features.

PVD, by contrast, is a line-of-sight process. The vaporized atoms travel in a straight line, making it difficult to coat undercuts or the inside of deep trenches.

Temperature and Substrate Sensitivity

Traditional CVD often requires very high temperatures to initiate the chemical reaction. This can damage or destroy thermally sensitive substrates, such as plastics or certain electronic components.

Techniques like PECVD were developed specifically to overcome this limitation by using plasma instead of heat. Many PVD processes can also operate at lower temperatures, making them suitable for a wider range of substrates.

Making the Right Choice for Your Application

Selecting a deposition method requires you to first define your non-negotiable requirements for the final product.

- If your primary focus is coating a complex 3D object uniformly: CVD is generally the superior choice due to its ability to conform to intricate surfaces.

- If your primary focus is depositing a very pure, high-density film of a metal or ceramic: PVD methods like sputtering or evaporation are often the industry standard.

- If your primary focus is depositing on a temperature-sensitive substrate like a polymer: Investigate specific low-temperature processes like Plasma-Enhanced CVD (PECVD) or certain PVD techniques.

Understanding these fundamental principles empowers you to select the precise deposition technique that meets your material and performance requirements.

Summary Table:

| Deposition Family | Key Principle | Common Applications |

|---|---|---|

| Physical Vapor Deposition (PVD) | Physically transports atoms from a source to a substrate. | High-purity metal/ceramic coatings, temperature-sensitive substrates. |

| Chemical Vapor Deposition (CVD) | Uses chemical reactions of precursor gases to form a film. | Uniform coatings on complex 3D objects, semiconductors, LEDs. |

Struggling to choose the right deposition method for your project? KINTEK specializes in lab equipment and consumables for all your deposition needs. Our experts can help you select the ideal PVD or CVD solution to achieve the precise film properties, purity, and conformity your application demands. Contact our team today to discuss your specific requirements and enhance your lab's capabilities.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method