Yes, a faulty furnace pressure switch can cause short cycling. While its primary role is to prevent ignition if a proper vent draft isn't established, an intermittent failure can cause the furnace to shut down mid-cycle. This happens when the switch incorrectly signals that the draft has been lost, forcing the system to stop the burners as a safety precaution, only to restart the process moments later.

While a failing pressure switch is a possible culprit for short cycling, its activation often signals a deeper problem. The switch is doing its job by reacting to an issue elsewhere in the system, most commonly a restriction in your furnace's venting or drainage lines.

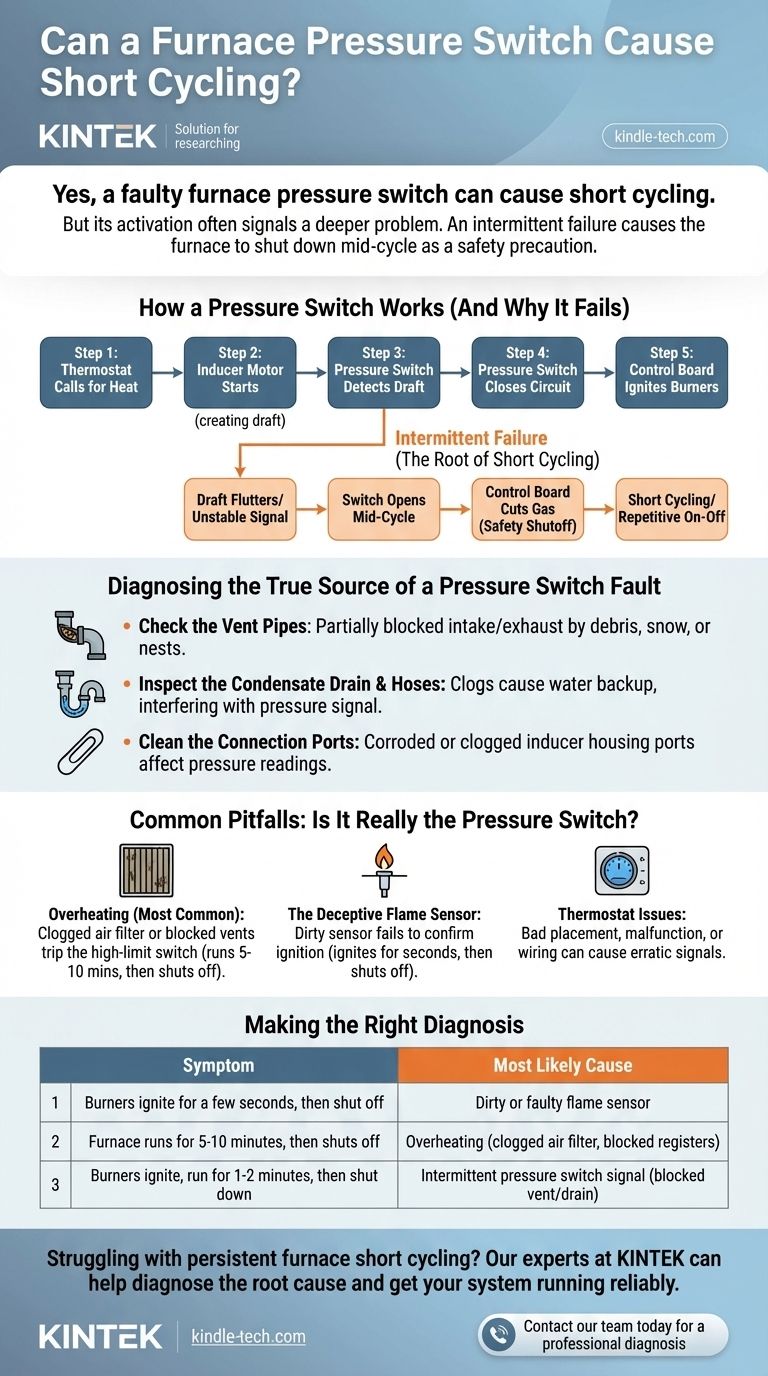

How a Pressure Switch Works (And Why It Fails)

A pressure switch is a fundamental safety device in modern furnaces. It acts as a gatekeeper, ensuring that toxic exhaust gases, like carbon monoxide, are being safely vented out of your home before allowing the main burners to ignite.

The Safety Handshake: From Draft to Ignition

When your thermostat calls for heat, the furnace control board first starts the inducer motor. This motor creates a small negative pressure, or draft, pulling air through the heat exchanger and out the vent pipe.

The pressure switch is designed to detect this specific draft. Once the correct pressure is achieved, the switch closes an internal circuit, sending an "all-clear" signal to the control board. Only then will the board proceed to ignite the burners.

The Intermittent Failure: The Root of Short Cycling

Short cycling occurs when the pressure switch's signal becomes unstable after the burners have already ignited.

If a partial blockage in a vent pipe or a failing inducer motor causes the draft to flutter, the pressure switch will open and close erratically. When it opens mid-cycle, the control board immediately cuts gas to the burners for safety. If the draft is re-established, the furnace may attempt to start the ignition sequence again, creating a short, repetitive on-off cycle.

Diagnosing the True Source of a Pressure Switch Fault

A pressure switch fault code rarely means the switch itself is broken. More often, it is correctly identifying a real problem with airflow or drainage. Before replacing the switch, you must investigate these common external causes.

Check the Vent Pipes

The most frequent cause of an intermittent pressure signal is a partially blocked intake or exhaust vent. These PVC pipes can be obstructed by leaves, snow, ice, or even an animal's nest. A quick visual inspection of the pipe terminations outside your home can often solve the problem.

Inspect the Condensate Drain and Hoses

High-efficiency furnaces produce condensation. If the condensate drain line or trap becomes clogged, water can back up into the inducer motor housing. This water can interfere with the pressure signal or even get into the small rubber hoses connected to the pressure switch, causing a blockage.

Clean the Connection Ports

The small rubber hose from the inducer housing connects to a port on the pressure switch. Over time, the port on the inducer housing can become corroded or clogged with debris. Gently removing the hose and clearing this port with a paperclip or small drill bit can restore a proper pressure reading.

Common Pitfalls: Is It Really the Pressure Switch?

Short cycling is a generic symptom with many potential causes. Misdiagnosing it as a pressure switch issue when it's something else can lead to wasted time and unnecessary repairs.

The Most Common Culprit: Overheating

The number one cause of short cycling is overheating. If the furnace cannot get rid of the heat it produces fast enough, a safety device called the high-limit switch will trip, shutting down the burners. This is most often caused by a severely clogged air filter or too many closed supply vents, which restrict airflow through your home.

The Deceptive Flame Sensor

If your furnace ignites for a few seconds and then shuts off, the problem is more likely a dirty flame sensor. This safety rod must be engulfed in flame to confirm ignition. If it's coated in soot, it can't send the proper signal, and the control board will shut off the gas.

Thermostat Placement and Malfunctions

A thermostat placed in direct sunlight, above a hot air vent, or near another heat source can get a false reading, causing it to shut the furnace off prematurely. A faulty thermostat or bad wiring can also cause erratic signals.

Making the Right Diagnosis for Your Furnace

To narrow down the cause, pay close attention to the sequence of events.

- If your furnace runs for 5-10 minutes then shuts off: Your issue is almost certainly overheating due to a clogged air filter or blocked registers.

- If your furnace's burners ignite for only a few seconds then shut off: This points directly to a dirty or faulty flame sensor needing to be cleaned or replaced.

- If the inducer motor starts, the burners ignite and run for a minute or two, then everything shuts down abruptly: This is the classic symptom of an intermittent pressure switch problem, which is most likely caused by a blockage in the vent pipes or condensate drain.

By understanding how these safety systems interact, you can move from guessing at the problem to methodically identifying the root cause of your furnace's behavior.

Summary Table:

| Symptom | Most Likely Cause |

|---|---|

| Burners ignite for a few seconds, then shut off | Dirty or faulty flame sensor |

| Furnace runs for 5-10 minutes, then shuts off | Overheating (clogged air filter, blocked registers) |

| Burners ignite, run for 1-2 minutes, then shut down | Intermittent pressure switch signal (blocked vent/drain) |

Struggling with persistent furnace short cycling?

Our experts at KINTEK can help you diagnose the root cause and get your lab or facility's heating system running reliably again. We specialize in providing dependable lab equipment and consumables to ensure your operations run smoothly.

Contact our team today for a professional diagnosis and let us help you maintain a safe, efficient environment.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the temperature range for quenching? Achieve Perfect Hardness for Your Steel Alloy

- What role does ammonolysis reaction equipment play in Co3Mo3N synthesis? Master High-Performance Catalyst Production

- How is a secondary vacuum annealing furnace used to study the failure mechanisms of protective coatings?

- What is the operating temperature of a batch type furnace? From 200°C to 3000°C for Your Specific Process

- What is the annealing process on properties? Achieve Softer, More Ductile Materials

- How does the discharge effect of a DC pulse power supply affect SPS nickel-based alloys? Achieve Rapid Densification

- What temperature is needed to braze stainless steel? The critical guide to alloy-specific brazing

- What is the role of a high-temperature furnace in the austenitizing process of Q345 steel? Optimize Heat Treatment