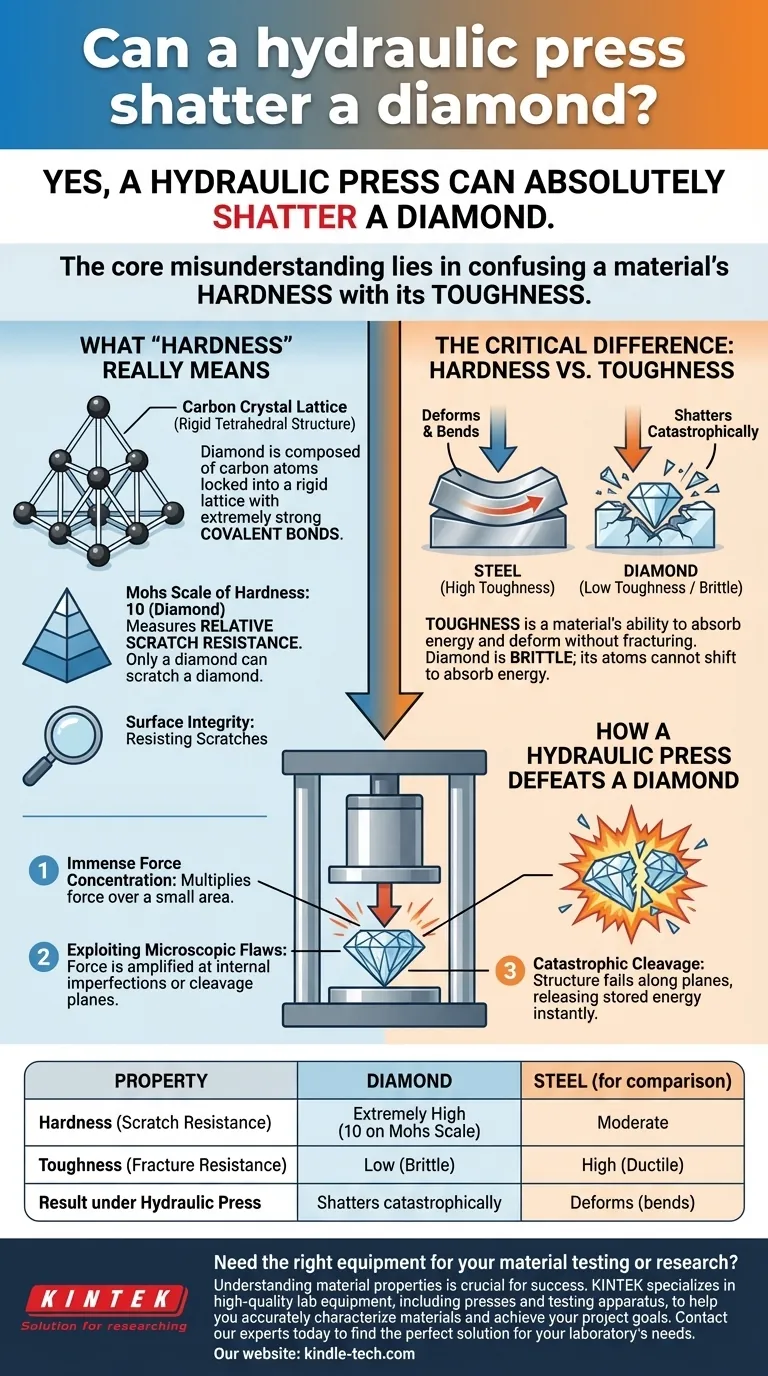

Yes, a hydraulic press can absolutely shatter a diamond. While diamonds are famously the hardest natural material on Earth, this hardness refers specifically to their incredible resistance to being scratched. When faced with the immense, focused compressive force of a hydraulic press, a diamond’s rigid crystal structure will fail, causing it to shatter catastrophically.

The core misunderstanding lies in confusing a material's hardness with its toughness. A diamond is extremely hard, meaning it resists surface scratches, but it is not tough, making it brittle and susceptible to shattering under sufficient impact or compressive force.

What "Hardness" Really Means

The reputation of a diamond is built on its unparalleled hardness. This property is a direct result of its unique atomic structure.

The Carbon Crystal Lattice

A diamond is composed of carbon atoms locked into a rigid, tetrahedral crystal lattice. Each carbon atom is bonded to four others with extremely strong covalent bonds.

These bonds are very short and very strong, making it incredibly difficult for another object to dislodge or scratch the atoms on the diamond's surface.

The Mohs Scale of Hardness

The Mohs scale, which ranks minerals from 1 (talc) to 10 (diamond), is purely a measure of relative scratch resistance.

A substance with a higher Mohs number can scratch any substance with an equal or lower number. A diamond can scratch steel, quartz, and even sapphire, but nothing can scratch a diamond except another diamond.

The Critical Difference: Hardness vs. Toughness

Understanding why a press can shatter a diamond requires separating the concepts of hardness and toughness. They are not the same property.

Hardness: Resisting Scratches

As established, hardness is about surface integrity. Think of it as the material's defense against intrusion or abrasion. A hardened steel file can't scratch a diamond.

Toughness: Resisting Fracture

Toughness is a material's ability to absorb energy and deform without fracturing. It is the opposite of brittleness.

Think of a steel beam. It can bend under a heavy load (deform) and bend back. This is high toughness. A glass rod, however, will not bend; it will simply snap. This is low toughness, or high brittleness.

A Diamond's Brittleness

The same rigid crystal structure that gives a diamond its hardness also makes it brittle. The atoms are locked so tightly that they cannot shift or deform to absorb energy.

Instead, when the force from a hydraulic press exceeds the strength of the atomic bonds along specific planes (called cleavage planes), the structure fails completely and instantly.

How a Hydraulic Press Defeats a Diamond

A hydraulic press creates the perfect conditions to exploit a diamond's primary weakness: its brittleness.

Immense Force Concentration

A hydraulic press multiplies force over a small area, generating immense pressure. This pressure overwhelms the diamond's structural integrity.

Exploiting Microscopic Flaws

Virtually all diamonds, even high-quality ones, have tiny internal imperfections or surface flaws.

Under immense pressure, these flaws act as stress concentration points. The force of the press is amplified at these weak spots, initiating a crack that propagates through the crystal lattice almost instantly.

Catastrophic Cleavage

Once a crack begins along one of the diamond's cleavage planes, the stored energy is released all at once. This results in the characteristic shattering effect rather than a simple crack or deformation.

Making the Right Choice for Your Goal

Understanding the distinction between these material properties is critical in engineering and design. The "strongest" material is only the best if its specific type of strength matches the intended application.

- If your primary focus is surface durability and wear resistance: Prioritize a material with high hardness, such as diamond coatings for cutting tools or sapphire for watch faces.

- If your primary focus is impact resistance and structural integrity: Prioritize a material with high toughness, such as steel for building frames or polycarbonate for safety glasses.

- If your primary focus is a balance of properties: You must look to engineered materials like composites or specific metal alloys designed to deliver both hardness and toughness.

Ultimately, a material's strength is not a single value but a profile of different characteristics, and knowing which one matters is the key to success.

Summary Table:

| Property | Diamond | Steel (for comparison) |

|---|---|---|

| Hardness (Scratch Resistance) | Extremely High (10 on Mohs Scale) | Moderate |

| Toughness (Fracture Resistance) | Low (Brittle) | High (Ductile) |

| Result under Hydraulic Press | Shatters catastrophically | Deforms (bends) |

Need the right equipment for your material testing or research? Understanding material properties like hardness and toughness is crucial for success. KINTEK specializes in high-quality lab equipment, including presses and testing apparatus, to help you accurately characterize materials and achieve your project goals. Contact our experts today to find the perfect solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- Is pressure constant in a hydraulic press? Unlock the Power of Force Multiplication

- Why are hydraulic presses required when studying FATT50? Precision Tools for Grain Refinement & Impact Toughness

- How does a laboratory hydraulic press ensure the quality of high-entropy ceramic green bodies? Get Perfect Sintering.

- What pressure should KBr pellets be? Optimize Your FTIR Spectroscopy with the Right Load

- How does a laboratory hydraulic press contribute to the formation of non-sintered LLZTO? Expert Densification Guide

- What are the components of a hydraulic press machine? A Guide to Core Parts & Functions

- How do you prepare a sample for XRD analysis? Achieve Accurate Crystal Structure Data

- How does a laboratory hydraulic press reduce interface impedance in solid-state batteries? Achieve Peak Ion Conductivity