Yes, hydraulic fluid can absolutely overheat. Overheating is one of the most common and destructive issues in hydraulic systems, occurring when the system generates more heat than it can dissipate. This excess heat is a direct symptom of inefficiency, and it rapidly degrades the fluid, damages components, and leads to premature system failure.

Overheating is not just a temperature problem; it's a critical indicator of wasted energy within your hydraulic system. Addressing the root cause of this inefficiency is essential to protect the fluid, prevent component damage, and ensure long-term reliability.

Why Heat is the Enemy of Hydraulic Systems

Every hydraulic system is designed to convert mechanical power into fluid power. However, no system is 100% efficient. The energy lost during this conversion is released as heat, and managing this heat is fundamental to the system's health.

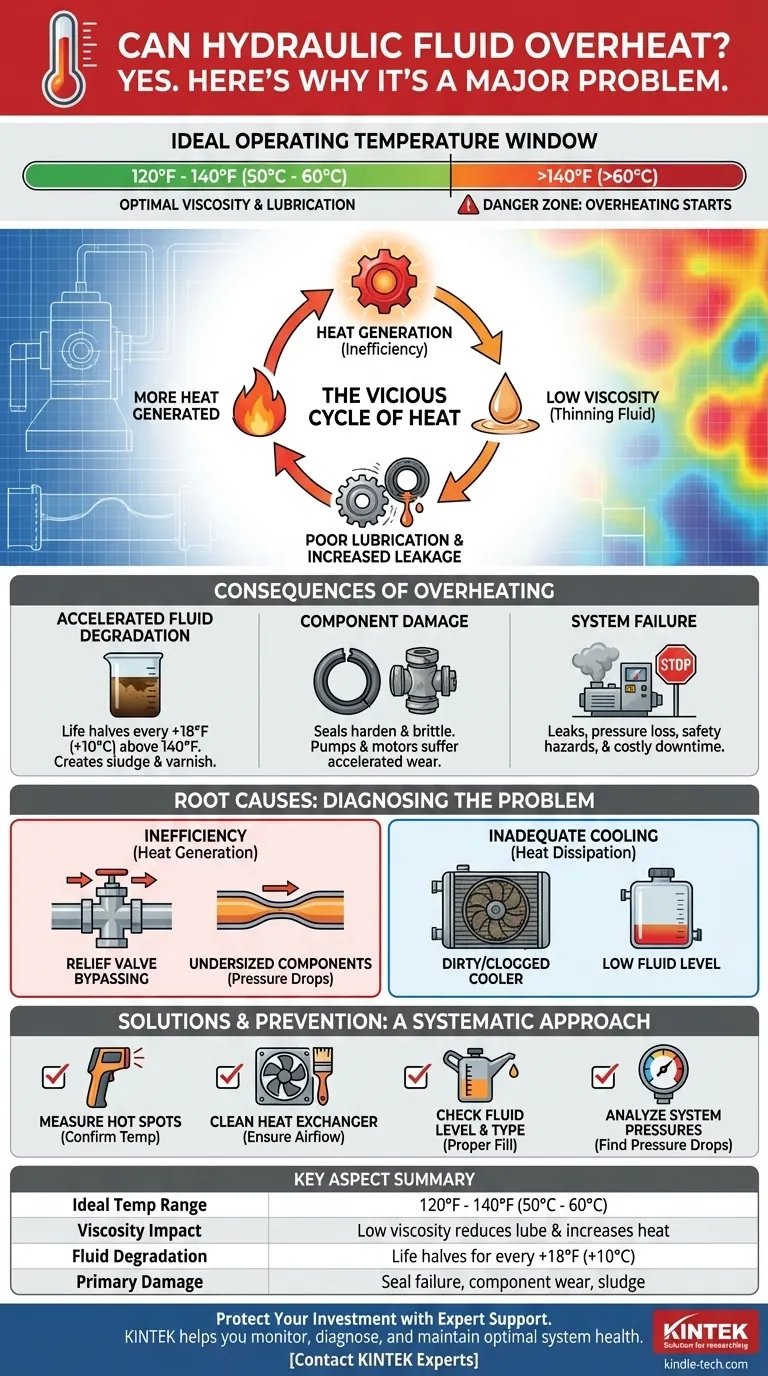

The Ideal Operating Temperature Window

Most hydraulic systems are designed to operate within a specific temperature range, typically 120°F to 140°F (50°C to 60°C).

Within this range, the hydraulic fluid maintains its optimal viscosity—its resistance to flow. This ensures efficient power transmission and proper lubrication of moving parts.

The Vicious Cycle of Low Viscosity

When the fluid temperature rises above its ideal range, its viscosity drops significantly. This "thinning" of the oil is the primary catalyst for damage.

Lower viscosity leads to reduced lubrication, allowing for more metal-to-metal contact inside pumps, motors, and valves. It also increases internal leakage (slippage), which makes the system less efficient and, in a destructive feedback loop, generates even more heat.

Accelerated Fluid Degradation

Heat is a catalyst for oxidation, the chemical reaction that breaks down hydraulic fluid. For every 18°F (10°C) increase in temperature above 140°F (60°C), the fluid's service life is cut in half.

This accelerated degradation creates sludge, varnish, and corrosive acids. Varnish can coat internal surfaces, causing valves to stick, while sludge clogs filters and orifices, starving the system of clean fluid.

Damage to Seals and Components

Excessive heat has a direct physical impact on system hardware. Seals and hoses, typically made of rubber or synthetic compounds, will harden, become brittle, and crack.

This leads to both internal and external leaks, reducing system pressure and creating safety and environmental hazards. The poor lubrication from low-viscosity fluid also causes accelerated wear on expensive components like pumps and motors.

Diagnosing the Root Causes of Overheating

Overheating is always a symptom of a deeper problem. The cause is either that the system is producing too much heat or that it is not dissipating heat effectively.

Inefficiency is the Primary Culprit

Heat is generated any time hydraulic fluid flows from an area of high pressure to low pressure without performing useful work. An infrared thermometer is an invaluable tool for finding these "hot spots."

Common sources include a relief valve that is set too low or is constantly open, or significant pressure drops across undersized hoses, valves, or clogged filters.

Inadequate Heat Dissipation

The hydraulic system's reservoir and cooler (heat exchanger) are responsible for removing heat. If this capability is compromised, temperatures will rise.

Check for a dirty or clogged cooler, a malfunctioning fan, or insufficient airflow around the reservoir. A low fluid level in the reservoir also reduces its ability to dissipate heat.

Environmental and Operational Factors

High ambient temperatures can overwhelm a system's cooling capacity, especially if the cooler was not sized for extreme conditions.

Similarly, operating the system continuously at maximum pressure and flow places a much higher thermal load on it than intermittent use.

Understanding the Trade-offs and Pitfalls

Addressing heat issues often involves balancing performance, cost, and complexity. Misunderstanding these trade-offs can lead to chronic problems.

The Relief Valve Problem

A pressure relief valve is a simple safety device, but it is a massive source of heat if fluid is constantly flowing across it. A system where the relief valve is frequently bypassing is fundamentally inefficient.

The correct solution is often a more sophisticated system design using variable displacement pumps or load-sensing controls, but this comes at a higher initial cost.

The Cost of Undersized Components

Using hoses, pipes, or valves that are too small for the required flow rate is a common design flaw. While it may save money upfront, it creates restrictions that lead to large pressure drops.

These pressure drops do no useful work and are converted directly into heat, costing far more in the long run through inefficiency and premature component failure.

The Limits of Air Cooling

Air-cooled heat exchangers are common and effective, but their performance is directly tied to the ambient air temperature.

In hot environments, an air cooler may be insufficient. Furthermore, their fins are highly susceptible to clogging with dust and debris, which requires diligent, routine cleaning to maintain effectiveness.

How to Solve and Prevent Overheating

A systematic approach is the best way to diagnose and resolve heat-related issues in a hydraulic system.

Start with Measurement

Use a reliable temperature gauge or an infrared thermometer to confirm the operating temperature. A thermal gun is excellent for scanning components to find specific hot spots that indicate a point of inefficiency.

Check the Cooling System First

The simplest and most common fixes are related to the cooling circuit. Ensure the heat exchanger is clean, the fan is operating correctly, and there is unobstructed airflow.

Analyze System Pressures

Measure pressures throughout the system to identify any unusually large pressure drops across specific components when the system is under load. This will pinpoint sources of inefficiency.

Ensure Proper Fluid and Fill Level

Verify that you are using the correct type and viscosity grade of hydraulic fluid for your system and operating conditions. Most importantly, ensure the reservoir is filled to the proper level.

Making the Right Choice for Your System's Health

Proactively managing thermal load is the key to a reliable and long-lasting hydraulic system.

- If you are troubleshooting an existing problem: Start with the simplest solutions—clean the cooler and check the fluid level before searching for sources of inefficiency with a pressure gauge and thermometer.

- If you are designing a new system: Do not undersize components. Invest in a properly sized cooling system for your expected ambient temperatures and duty cycle.

- For routine maintenance: Make cleaning the heat exchanger and checking fluid health a non-negotiable part of your schedule to prevent problems before they start.

Ultimately, treating your system's temperature as a vital sign is the most effective way to ensure its long-term health and performance.

Summary Table:

| Key Aspect | Critical Information |

|---|---|

| Ideal Temp Range | 120°F to 140°F (50°C to 60°C) |

| Viscosity Impact | Low viscosity reduces lubrication & increases heat |

| Fluid Degradation | Life halves for every 18°F (10°C) above 140°F |

| Common Causes | Relief valve issues, clogged cooler, undersized components |

| Primary Damage | Seal failure, component wear, sludge/varnish buildup |

Is your hydraulic system running hot? Protect your investment with expert support.

At KINTEK, we understand that overheating is a symptom of deeper inefficiencies that can lead to costly downtime and component failure. Our team specializes in providing the precise lab equipment and consumables needed to monitor, diagnose, and maintain optimal hydraulic system health.

We help you:

- Accurately monitor system temperatures and pressures with reliable measurement tools.

- Identify root causes of inefficiency to prevent recurring problems.

- Select the right fluids and components for your specific operating conditions.

Don't let heat damage derail your operations. Contact our hydraulic experts today for personalized solutions that extend equipment life and maximize reliability.

Visual Guide

Related Products

- Manual Lab Heat Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Lab Infrared Press Mold

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

People Also Ask

- What is KBr in chemistry? Discover Its Role in IR Spectroscopy and Beyond

- What are the applications of laboratory hydraulic presses in phase-transfer catalytic desulfurization research? Achieve Precise Catalyst Pelletization

- What happens if hydraulic pressure is too low? Avoid System Failure and Costly Damage

- What is the role of a laboratory hydraulic press in the solid-phase reduction of red mud? Optimize Sponge Iron Quality

- Is compression molding a fast process? A Guide to Faster Time-to-Market for Low-Volume Production

- What is the primary purpose of a laboratory hydraulic press for EIS testing on RPPO? Ensure Reliable Data Accuracy

- What are 3 important maintenance procedures for hydraulic systems? Prevent Costly Failures & Downtime

- How are laboratory hydraulic presses and pellet dies used in mechanochemistry? Unlock Precision in Solid-State Research