Yes, stainless steel can be PVD coated. In fact, stainless steel is considered an ideal base material, or substrate, for the Physical Vapor Deposition (PVD) process. The inherent properties of stainless steel allow the PVD coating to form an exceptionally strong and durable bond, enhancing the final product's performance and aesthetic qualities without requiring an intermediate plating layer.

The core principle to understand is that PVD coating on stainless steel is not about fixing a weakness, but about enhancing a strength. It adds a thin, extremely hard ceramic layer that elevates wear resistance and offers a vast palette of colors, all while leveraging the foundational durability and corrosion resistance of the steel itself.

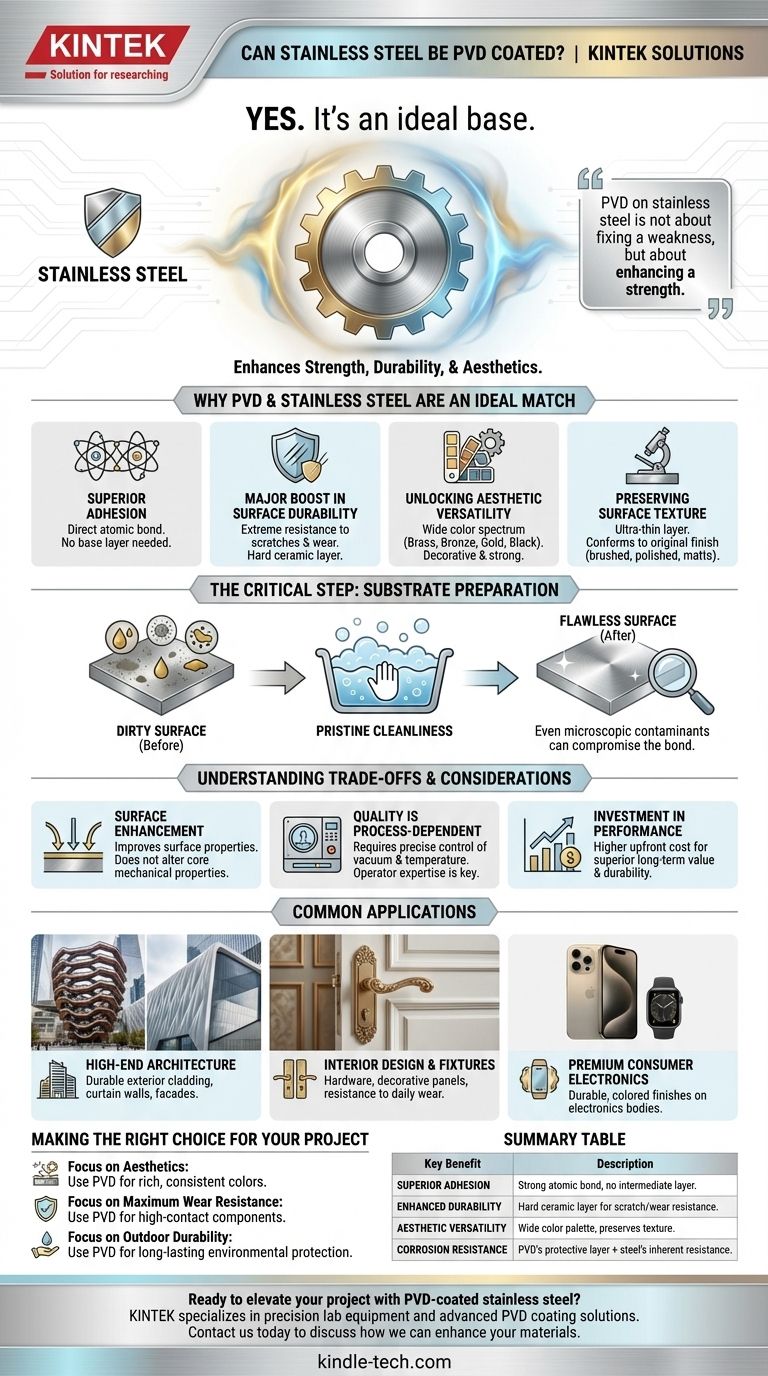

Why PVD and Stainless Steel Are an Ideal Match

The synergy between these two materials is a key reason for their widespread use in demanding applications. The combination delivers benefits that neither material can achieve alone.

Superior Adhesion

Stainless steel provides an excellent surface for PVD coatings. Unlike other metals that might require a base layer of nickel or chrome, PVD materials can be applied directly, forming a powerful atomic bond. This direct adhesion results in a more robust and reliable finish.

A Major Boost in Surface Durability

While stainless steel is already durable, a PVD coating adds a significant layer of protection. This vapor-deposited ceramic layer dramatically increases resistance to scratches, abrasions, and daily wear, protecting the steel from environmental factors and maintaining its original luster.

Unlocking Aesthetic Versatility

PVD coating liberates stainless steel from its classic silver appearance. By varying the gasses and metals used in the vacuum chamber, a wide spectrum of colors can be produced, including brass, bronze, gold, black, and even iridescent finishes. This allows for the aesthetic of a decorative metal with the superior strength of steel.

Preserving the Original Surface Texture

The PVD process deposits an extremely thin layer, typically only a few microns thick. This means the coating perfectly conforms to the original surface of the stainless steel, whether it's a brushed, polished, or matte finish. The underlying texture is preserved, not obscured.

The Critical Step: Substrate Preparation

The success of any PVD coating application hinges on one non-negotiable factor: cleanliness. The process occurs at a microscopic level, and any foreign material can compromise the bond between the coating and the steel.

The Importance of a Pristine Surface

Before entering the PVD vacuum chamber, the stainless steel part must be flawlessly clean. Any oils, grease, dust, or other contaminants will prevent the coating from adhering properly, leading to potential defects or failure of the finish.

How Contamination Affects Quality

Even a microscopic speck of dust can create a pinhole or weak spot in the coating. Proper cleaning is the first and most critical step in the quality control process, ensuring a consistent, high-quality finish across the entire part.

Understanding the Trade-offs and Considerations

While the combination is highly effective, it's important to approach it with a clear understanding of its characteristics and limitations.

It's a Surface Enhancement, Not a Base Metal Change

A PVD coating improves the surface properties of the steel, such as hardness and color. It does not alter the underlying mechanical properties, like tensile strength or flexibility, of the stainless steel part itself.

Quality is Process-Dependent

Although the PVD process is robust and has a large operating window, the final quality is highly dependent on the operator's expertise and the quality of their equipment. Consistent results require precise control over the vacuum, temperature, and deposition materials.

It's an Investment in Performance

PVD is an advanced finishing process. While it can be economically beneficial by eliminating the need for other plating layers, it represents a greater upfront investment than simpler finishes like painting or powder coating. Its value is realized in superior long-term performance and durability.

Where This Combination Excels: Common Applications

The blend of aesthetic versatility and extreme durability has made PVD-coated stainless steel a preferred choice in several high-profile industries.

High-End Architecture

From the exterior cladding on landmark structures like The Vessel in New York City to curtain walls, profiles, and facades on luxury hotels and retail stores, PVD provides a durable, weather-resistant, and visually striking finish.

Interior Design and Fixtures

The coating is commonly used for interior hardware, decorative panels, and fixtures where both a specific look and resistance to daily wear are required.

Premium Consumer Electronics

PVD is the technology behind many of the durable, colored finishes on high-end electronics. The iconic Space Gray and Gold finishes on products like the iPhone and Apple Watch are achieved by applying a PVD coating to a stainless steel body.

Making the Right Choice for Your Project

To determine if this process is right for you, consider your primary goal.

- If your primary focus is aesthetics: Use PVD to achieve rich, consistent finishes like brass, bronze, or black on a strong, corrosion-resistant stainless steel base.

- If your primary focus is maximum wear resistance: PVD provides a significant upgrade in surface hardness, making it ideal for high-contact components that need to resist scratches and abrasion.

- If your primary focus is outdoor durability: The combination of a PVD coating and stainless steel offers superior, long-lasting protection against environmental conditions and discoloration.

By pairing PVD with stainless steel, you are strategically enhancing an already high-performance material to meet the most demanding functional and aesthetic requirements.

Summary Table:

| Key Benefit | Description |

|---|---|

| Superior Adhesion | Forms a strong atomic bond directly with stainless steel, no intermediate layer needed. |

| Enhanced Durability | Adds a hard ceramic layer for superior scratch, abrasion, and wear resistance. |

| Aesthetic Versatility | Enables a wide color palette (gold, black, bronze) while preserving surface texture. |

| Corrosion Resistance | Combines PVD's protective layer with stainless steel's inherent rust resistance. |

Ready to elevate your project with PVD-coated stainless steel?

KINTEK specializes in precision lab equipment and consumables, including advanced PVD coating solutions for stainless steel. Whether you're in architecture, consumer electronics, or interior design, our expertise ensures a durable, high-quality finish that meets your exact specifications.

Contact us today to discuss how we can enhance your materials with superior PVD coating technology!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition